Bernardo

HBS 150 Z Horizontal Band Saw Combo with Coolant

€1.299,00€1.372,87Unit price /UnavailableBernardo

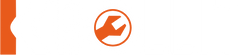

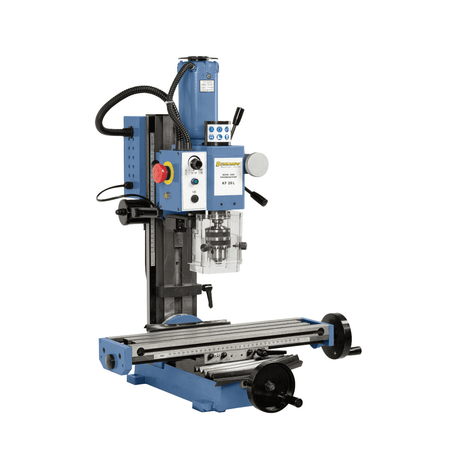

KF16 L Vario Drill/Milling Machine incl. three-axis digital display

€1.903,20Unit price /UnavailableBernardo

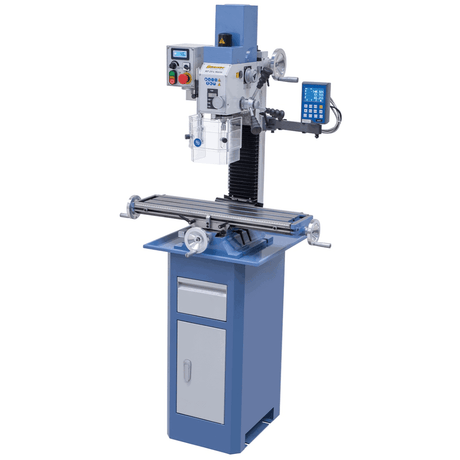

FM 50 HSV drilling and milling machine with 3-axis position display

€5.038,60Unit price /UnavailableBernardo

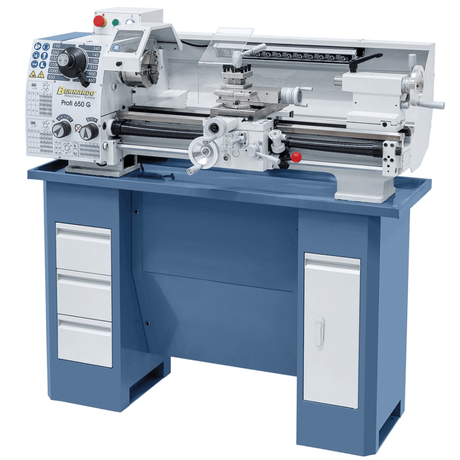

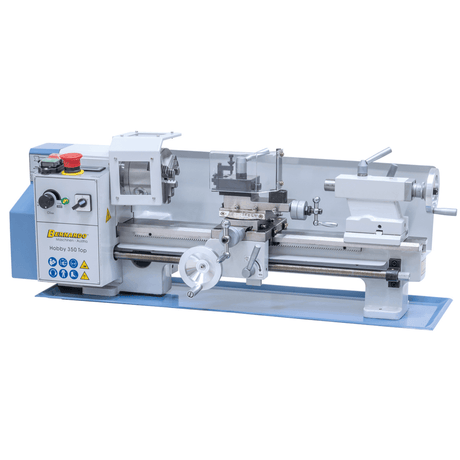

Metal lathe with guide spindles or arbor spindles Profi 650 G / 230 V

€3.245,00Unit price /UnavailableBernardo

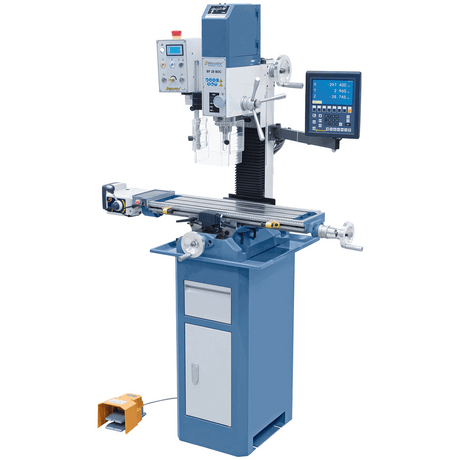

KF 25 Pro drilling and milling machine with feed and position display.

€3.257,40Unit price /UnavailableBernardo

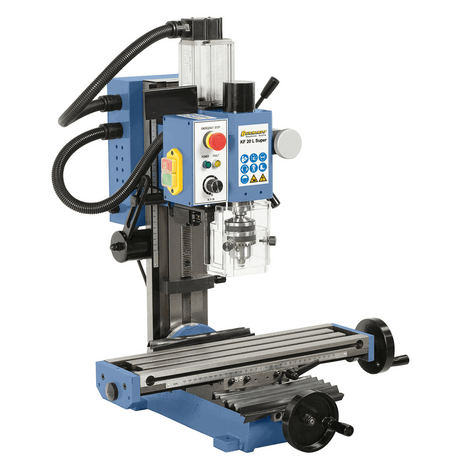

KF 25 L Vario drilling and milling machine with 3-axis digital display

€2.427,80Unit price /UnavailableBernardo

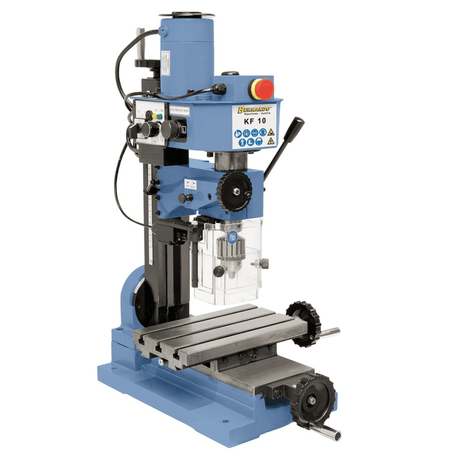

BF 35 BDC Drill and Milling Machine with 3-Axis Feed and Digital Display

€4.209,00Unit price /UnavailableBernardo

BF 28 BDC drilling and milling machine with 3-axis feed and position display

€3.440,40Unit price /UnavailableBernardo

Proficenter 650 G - 230V metal lathe with display and milling machine

€4.867,00Unit price /Unavailable

Frequently Asked Questions

Quali macchine servono per aprire una piccola officina?

Quali macchine servono per aprire una piccola officina?

Meglio macchine monofase 230V o trifase 400V?

Meglio macchine monofase 230V o trifase 400V?

Meglio un tornio convenzionale o CNC per iniziare?

Meglio un tornio convenzionale o CNC per iniziare?

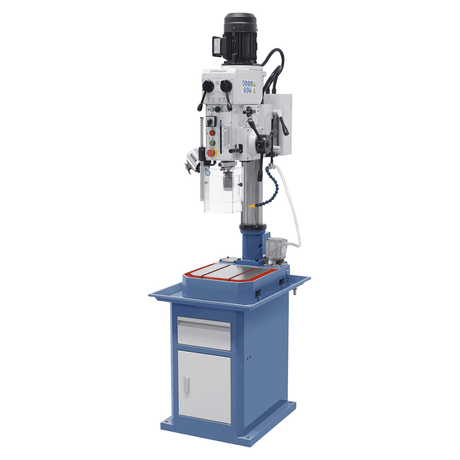

Che differenza c'è tra trapano a colonna e trapano-fresa?

Che differenza c'è tra trapano a colonna e trapano-fresa?

Quali sono i costi di manutenzione ordinaria?

Quali sono i costi di manutenzione ordinaria?

Quanto spazio serve per una piccola officina attrezzata?

Quanto spazio serve per una piccola officina attrezzata?