Bernardo | SKU:

04-1560XL

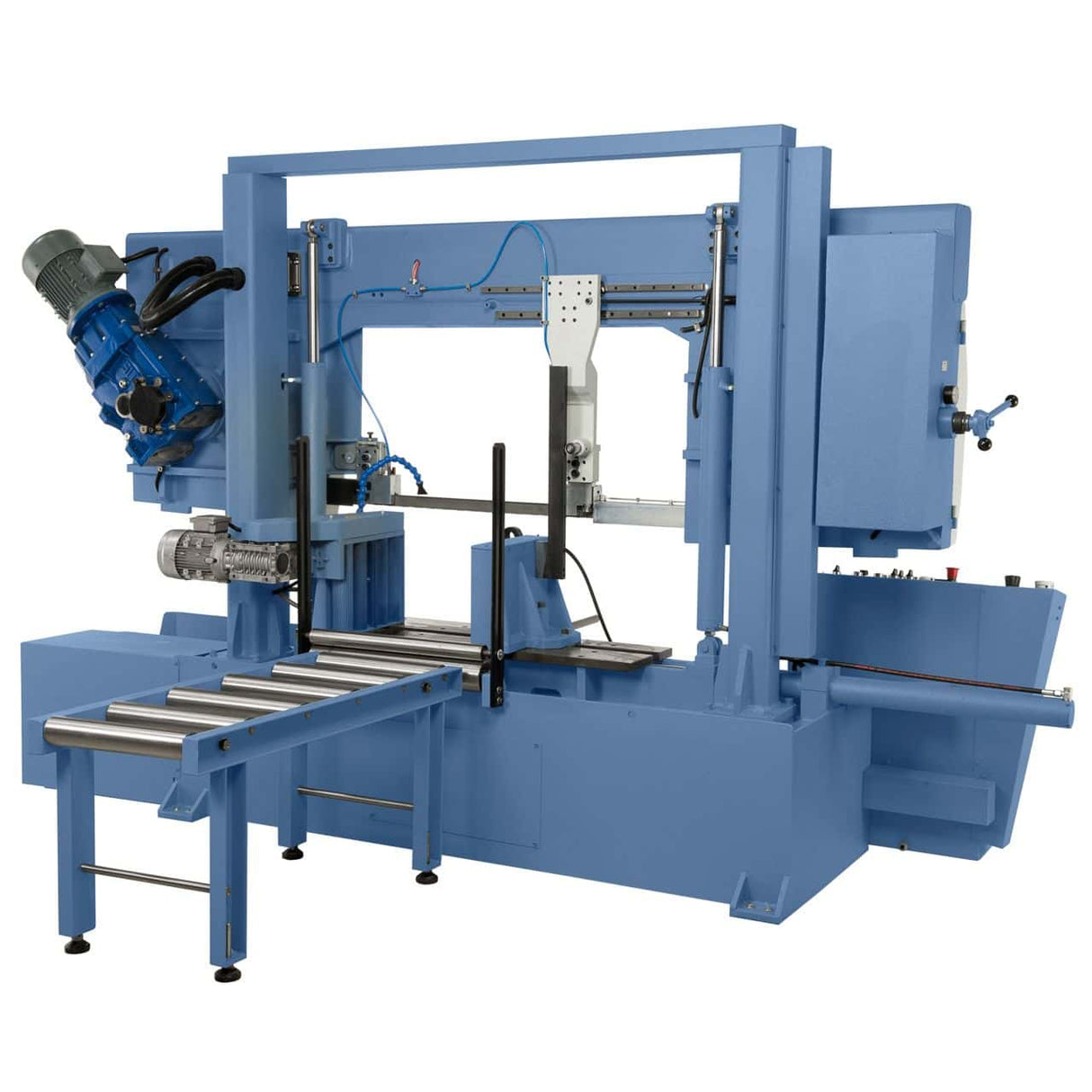

Fully automatic metal band saw MSB 560 V

Fully automatic metal band saw MSB 560 V is backordered and will ship as soon as it is back in stock.

Delivery and Shipping

Delivery and Shipping

Add some general information about your delivery and shipping policies.

-

Description

-

Technical Specifications

-

Product safety

-

Reviews

Description

The MSB 560 V fully automatic metal band saw is an excellent solution for a variety of industrial applications thanks to its advanced features and precision. One of the main advantages of this machine is the saw frame's approach via a finely honed linear guide. This means the saw frame moves smoothly and precisely along the cutting direction, ensuring accurate and uniform cuts on solid blocks of material.

This feature makes the MSB 560 V particularly suitable for processing robust and solid materials, such as metal blocks or other hard materials. The ability to make precise cuts on such materials is essential in many industries, where precision and cut quality are essential to ensure compliance with production standards and the safety of the final products.

Overall, the MSB 560 V fully automatic metal band saw stands out for its precision, its ability to work with solid materials, and its versatility. This machine is therefore an excellent choice for cutting needs in industries where quality, efficiency, and precision are paramount.

Property

- Fully automatic operation, including automatic saw arm lifting : The saw operates fully automatically, including automatically lifting the saw arm after each cut. This eliminates the need for manual intervention, increasing efficiency and reducing working time.

- Manually adjustable workpiece feed length : The workpiece feed length can be manually adjusted according to the size of the material being cut, providing flexibility and adaptability to the specific needs of the job.

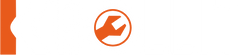

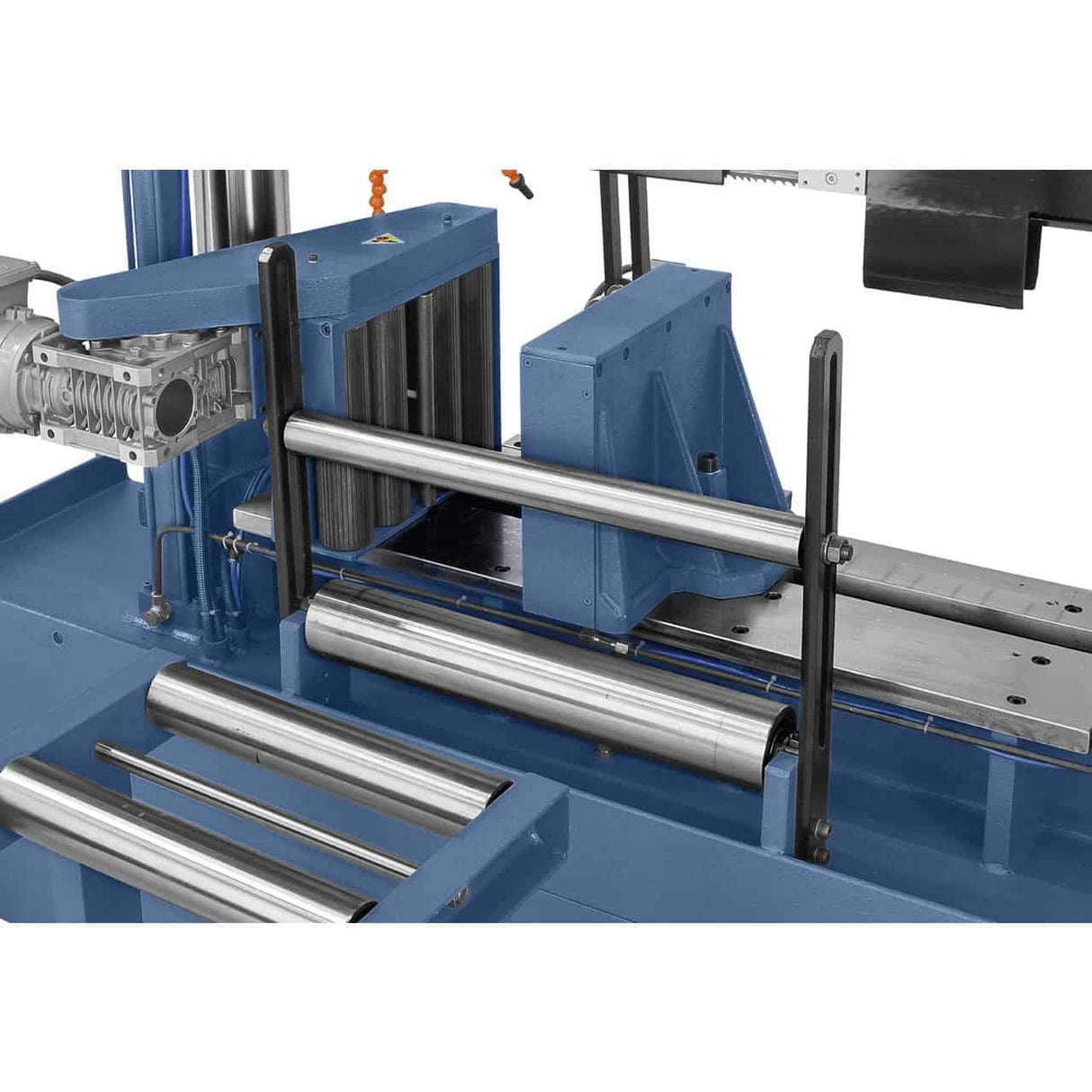

- The material is fed into the saw through motorized rollers in the vice, ensuring smooth and precise feed during cutting.

- Equipped with a bundle clamping device for cutting material packets : The presence of a bundle clamping device allows the material to be kept firmly fixed during cutting, ensuring accurate results even on material packets.

- Continuously adjustable speed, ideal for different materials : The saw speed can be continuously adjusted, allowing the machine to be adapted to different materials and thicknesses, ensuring optimal cutting results in every situation.

- Automatic blade breakage control stops the machine in the event of a blade breakage : A safety function automatically stops the saw from operating in the event of a blade breakage, ensuring operator safety and machine protection.

- Programmable number of pieces, ideal for series production : The machine allows the programming of the number of pieces to be cut, ideal for series production, allowing effective process automation.

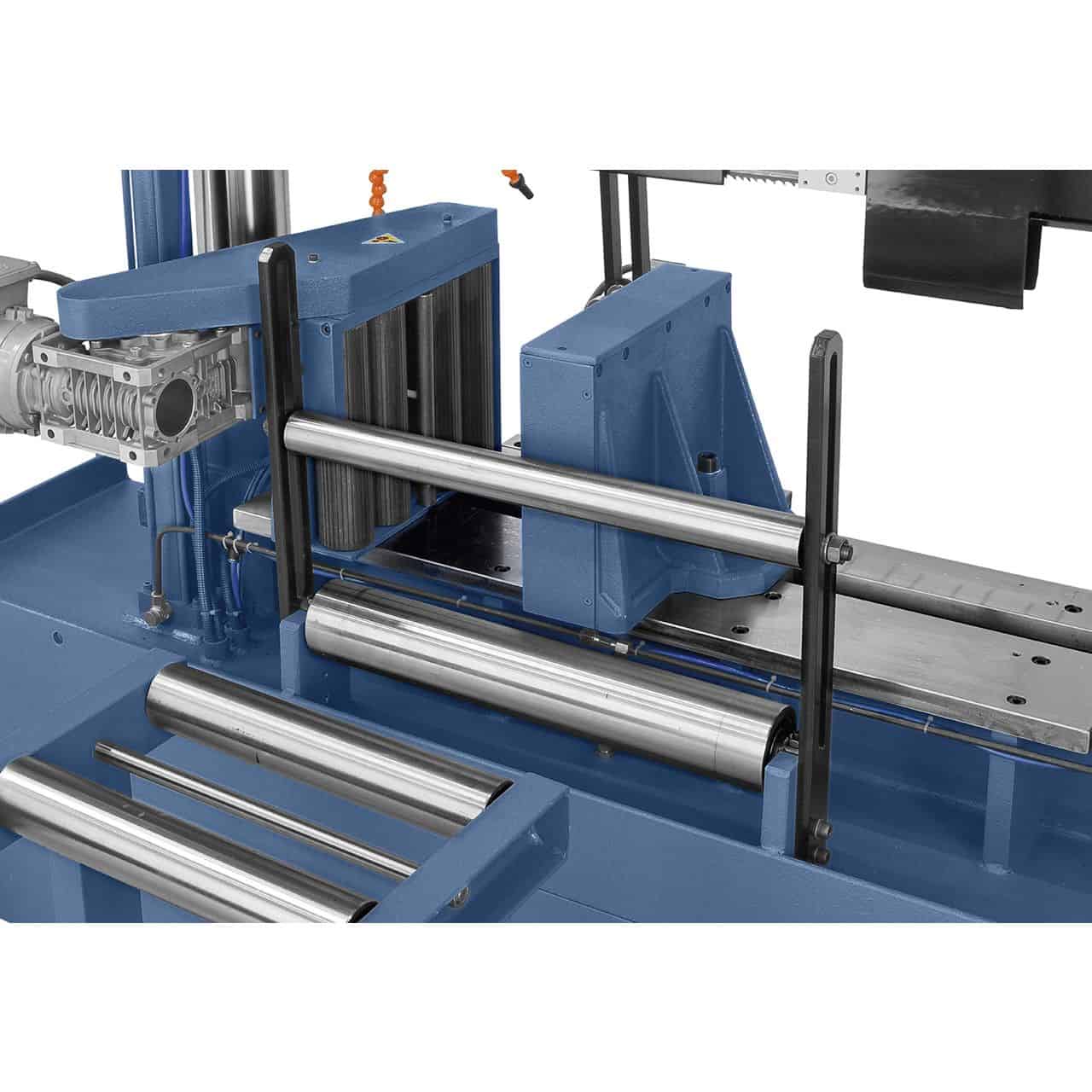

- Equipped with a pressure gauge for optimal adjustment of the belt tension : The presence of a pressure gauge allows you to optimally adjust the belt tension, ensuring a long blade life and precise cutting results.

- Greater stability through the precision guide for parallel cuts : A precision guide ensures greater stability when making parallel cuts, minimizing deviations and ensuring accurate and uniform results.

Standard accessories

- Saw band

- Piece stop

- Pressure gauge for tensioning the belt

- Hydraulic vice

- Refrigeration system

- Hydraulic cylinder

- Engine saver

- Automatic blade breakage control

- Automatic limit switch

- Hydraulic beam clamping device

- Roller conveyor

technical specifications

| 90° round cutting area | 560 mm |

| 90° flat cutting area | 570 x 560 mm |

| 90° square cutting area | 560 x 560 mm |

| Working height | 590 mm |

| Cutting speed, continuous | 20 - 100 m/min |

| Saw band dimensions | 6000 x 41 x 1.3 mm |

| Coolant circulation pump | 120 W |

| Engine power | 4.0 kW |

| Machine dimensions (L x W x H) | 3500 x 1050 x 2050 mm |

| Weight approx. | 2010 kg |

Technical Specifications

È adatta per acciai pieni, inox, tubi, profili e metalli non ferrosi di grandi dimensioni, con avanzamento automatico.

La macchina gestisce sollevamento e discesa del braccio, programmando numero di pezzi e avanzamento con rulli motorizzati.

A 90°: 560 mm tondo, 570 x 560 mm piatto, 560 x 560 mm quadro.

Sì, è dotata di un refrigerante da 120 W che mantiene la lama efficiente e prolunga la durata durante i tagli intensivi.

Integra controllo automatico rottura lama, spegnimento automatico e interruttore di protezione motore.

È consegnata in imballo protettivo, completa di lama, morsa idraulica, rulli motorizzati, serraggio superiore e manuale d’uso.