Bernardo | SKU:

04-1809

Pre-order

Vertical band saw with automatic table feed VMS 1000 A

€16.928,40

Unit price

/

Unavailable

Tax included

Shipping calculated at checkout.

Vertical band saw with automatic table feed VMS 1000 A is backordered and will ship as soon as it is back in stock.

Subscribe to our newsletter

Get the latest updates on all our new collections, sales, offers and product arrival dates.

-

Description

-

Technical Specifications

-

Product safety

-

Reviews

Description

The VMS 1000 A vertical bandsaw features automatic table advance, a feature that optimizes the cutting process, improving efficiency and productivity. This automatic advance allows the machine to feed material continuously and evenly during cutting, minimizing manual intervention and ensuring a smoother, more continuous workflow.

Thanks to its versatility, the VMS 1000 A can cut a wide range of materials, including steel, plastic, and non-ferrous metals. The VMS 1000 A is designed to offer high performance and reliability in material processing.

Property

- Solid cast iron table : The saw table is made of cast iron, providing a large, sturdy surface to support materials during the cutting process. This ensures a safe and stable working environment, reducing the risk of unwanted movement during operation.

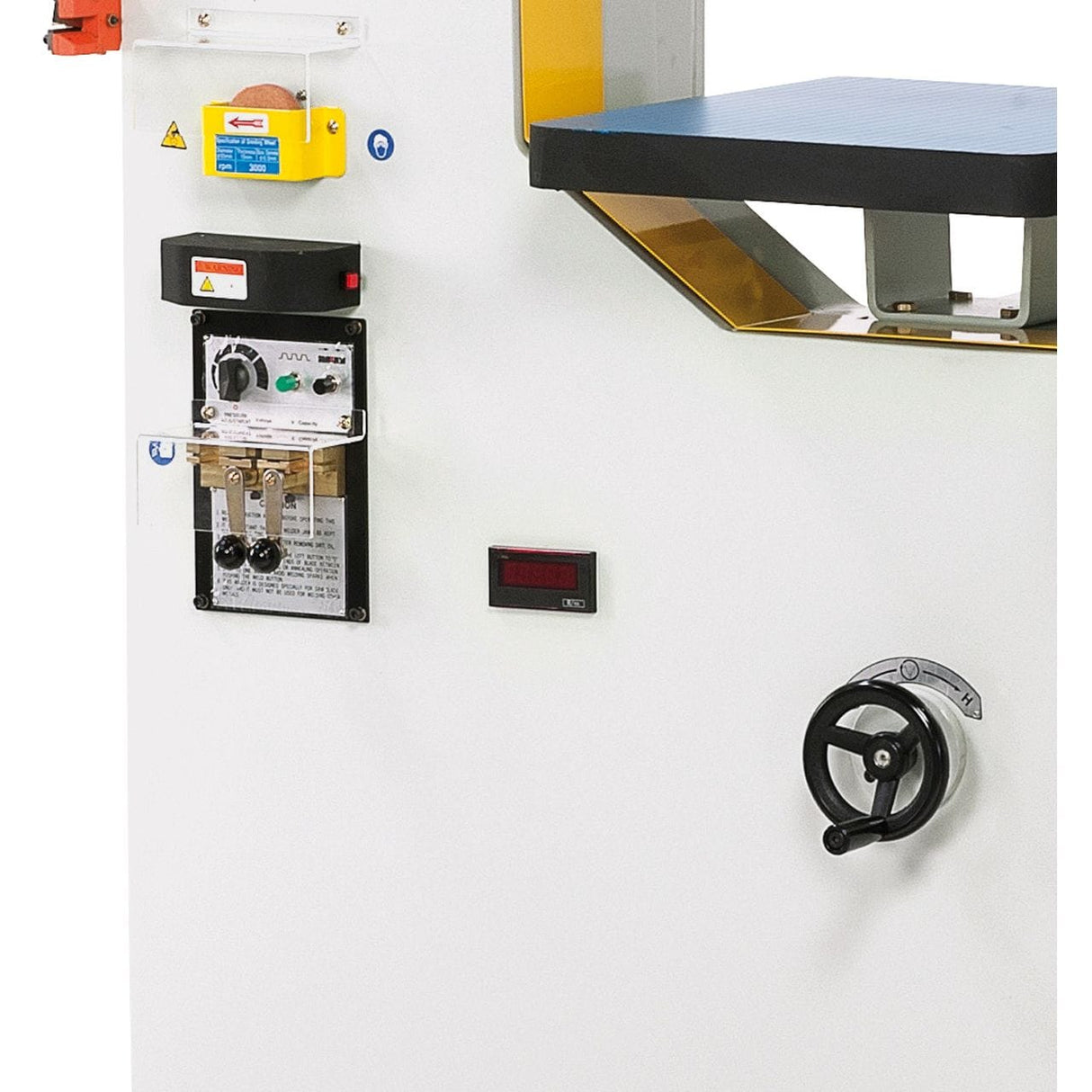

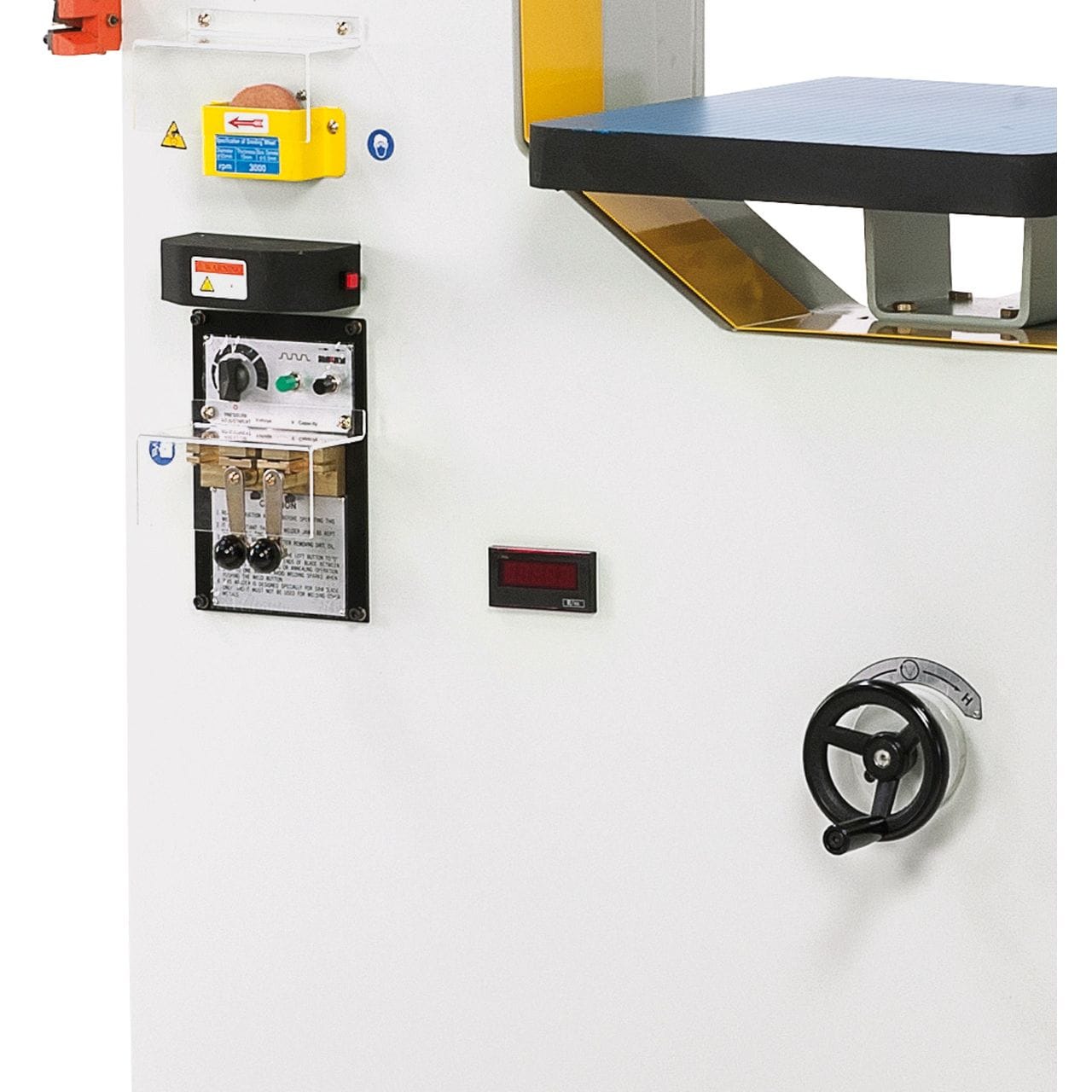

- Band welding device, annealing, cutting, and grinding device : The saw is equipped with a multifunctional device that allows band welding, annealing, cutting, and blade sharpening directly on the machine. This ensures efficient blade maintenance and reduces machine downtime, increasing overall productivity.

- Continuously adjustable cutting speed up to 500 m/min as standard : The cutting speed can be continuously adjusted up to 500 meters per minute, offering flexibility and precision during the machining process. This feature allows the speed to be adapted to the specific requirements of the material and type of cutting.

- Machine body made of sturdy steel construction : The machine body is made of sturdy steel construction, ensuring quiet operation and greater durability even in demanding work environments. This ensures structural stability and reduced vibration during use.

- Band guide with hardened and ground V-shaped guide jaws : The saw is equipped with a band guide with hardened and ground V-shaped guide jaws. This system provides precise blade guidance during cutting, ensuring optimal cutting results and longer blade life.

- Ideal for cutting contours and complex shapes : Thanks to its precision and versatility, the saw is ideal for cutting contours and complex shapes. This allows you to create detailed and intricate work with ease.

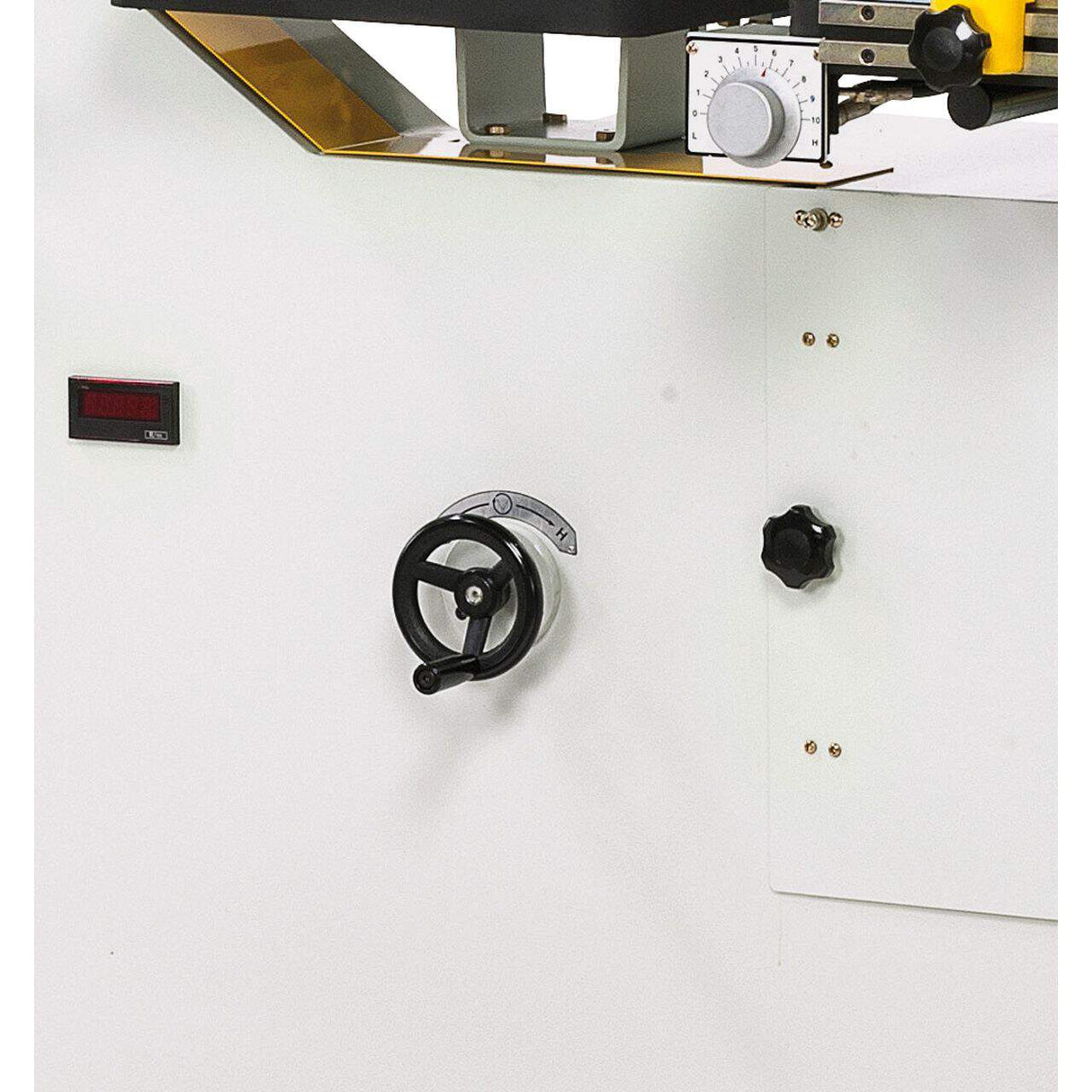

- Blade tension adjustment is done via the handwheel : The blade tension can be adjusted via a handwheel, allowing for precise control and quick correction of the blade tension while cutting.

- Blower with included compressor : The saw is equipped with a blower that uses an included compressor. This helps keep the work area clean and effectively removes chips and debris during the cutting process, improving efficiency and safety.

- For radial arm saws, 3 mm wide saw blades are available . For radial arm saws, 3 mm wide saw blades are available. This offers greater precision and flexibility during the cutting process, allowing you to achieve optimal cutting results even in more detailed cutting situations.

Standard accessories

- Saw band

- Band welding device with an annealing device

- Halogen lighting

- Cut

- Grindstone

- Chip brush

- Blowing device

- LED digital display

- Longitudinal stop

- Oblique beat

- Table length groove

technical specifications

| Cutting width | 1010 mm |

| Cutting height | 340 mm |

| Working height | 1000 mm |

| Cutting speed, level 1 | 20 – 85 m/min |

| Cutting speed, level 2 | 120 – 500 m/min |

| Saw band length | 4540 mm |

| Saw blade width | 3 – 20 mm |

| Table dimensions | 660 x 700 mm |

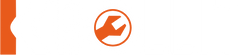

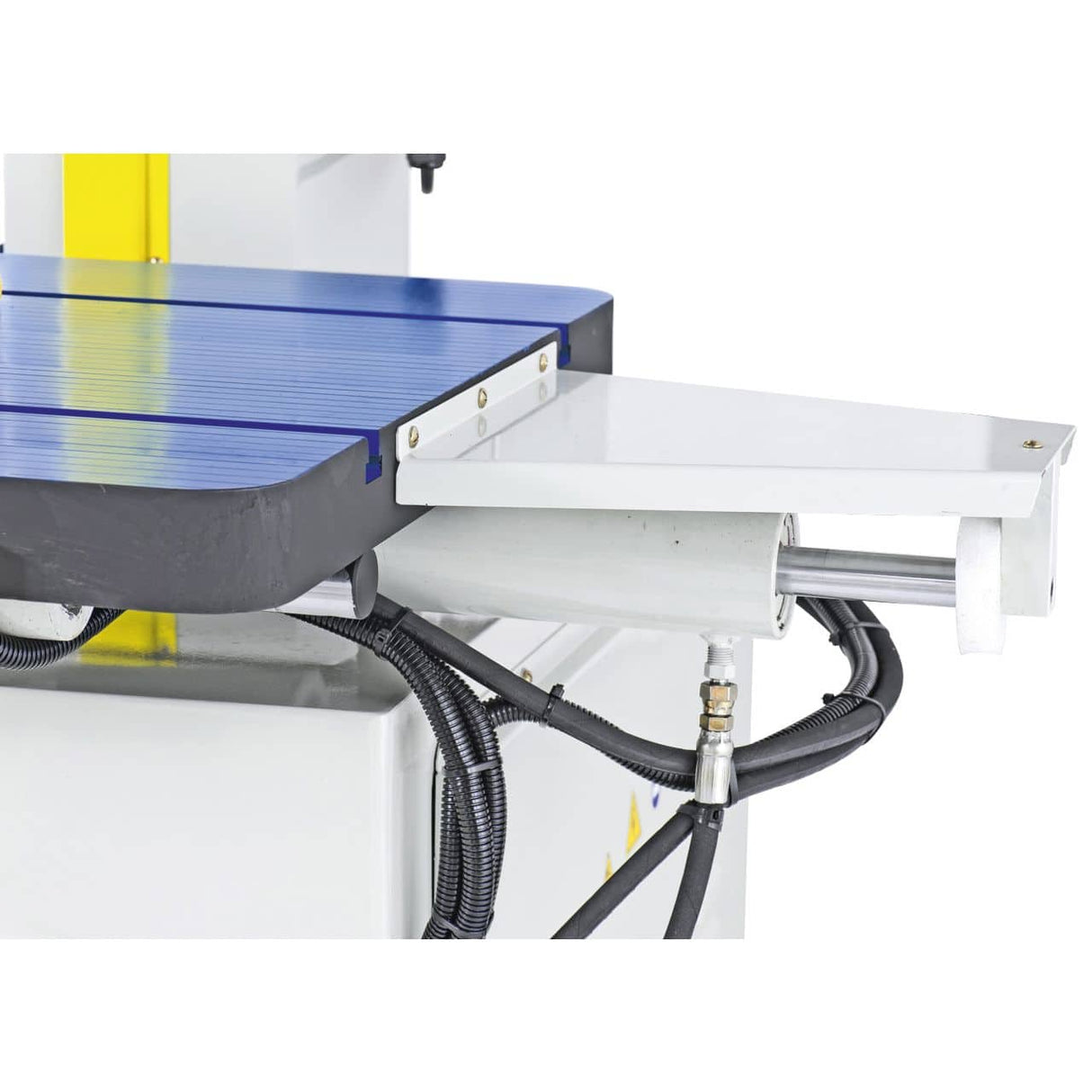

| Additional table dimensions | 450 x 490 mm |

| Table tilt area | S 5° / D 15° |

| Table race | 350 mm |

| Engine power | 1.5 kW |

| Sheet welding equipment | 4.2 kVA |

| Machine dimensions (L x W x H) | 1920 x 1110 x 2140 mm |

| Weight approx. | 950 kg |

Technical Specifications

È adatta per acciai, inox, metalli non ferrosi e materiali sagomati, perfetta per tagli complessi e lavorazioni di precisione.

L’avanzamento automatico riduce lo sforzo manuale, garantisce tagli costanti e migliora la produttività nelle lavorazioni seriali.

Capacità 1010 mm in larghezza e 340 mm in altezza, tavolo inclinabile L 5° / R 15°, corsa tavolo 350 mm.

Sì, è ideale per sagome complesse. Con lame da 3 mm è possibile realizzare raggi stretti e dettagli precisi.

Include saldatrice lama, cesoia, mola, chip brush, luce alogena, pistola ad aria compressa, LED display, guida parallela, guida angolare e tavolo scanalato.

È consegnata in imballo protettivo, completa di lama, saldatrice integrata, cesoia, mola, pistola ad aria compressa e manuale d’uso.