Bernardo | SKU:

06-1949XL

MTA 2060 x 3 mm NCC Motorized Guillotine Shear

MTA 2060 x 3 mm NCC Motorized Guillotine Shear is backordered and will ship as soon as it is back in stock.

Delivery and Shipping

Delivery and Shipping

Add some general information about your delivery and shipping policies.

-

Description

-

Technical Specifications

-

Product safety

-

Reviews

Description

Property

- Equipped as standard with a sheet metal support device, ideal for thin sheet metal

- Support arms on the front for easy processing of large panels

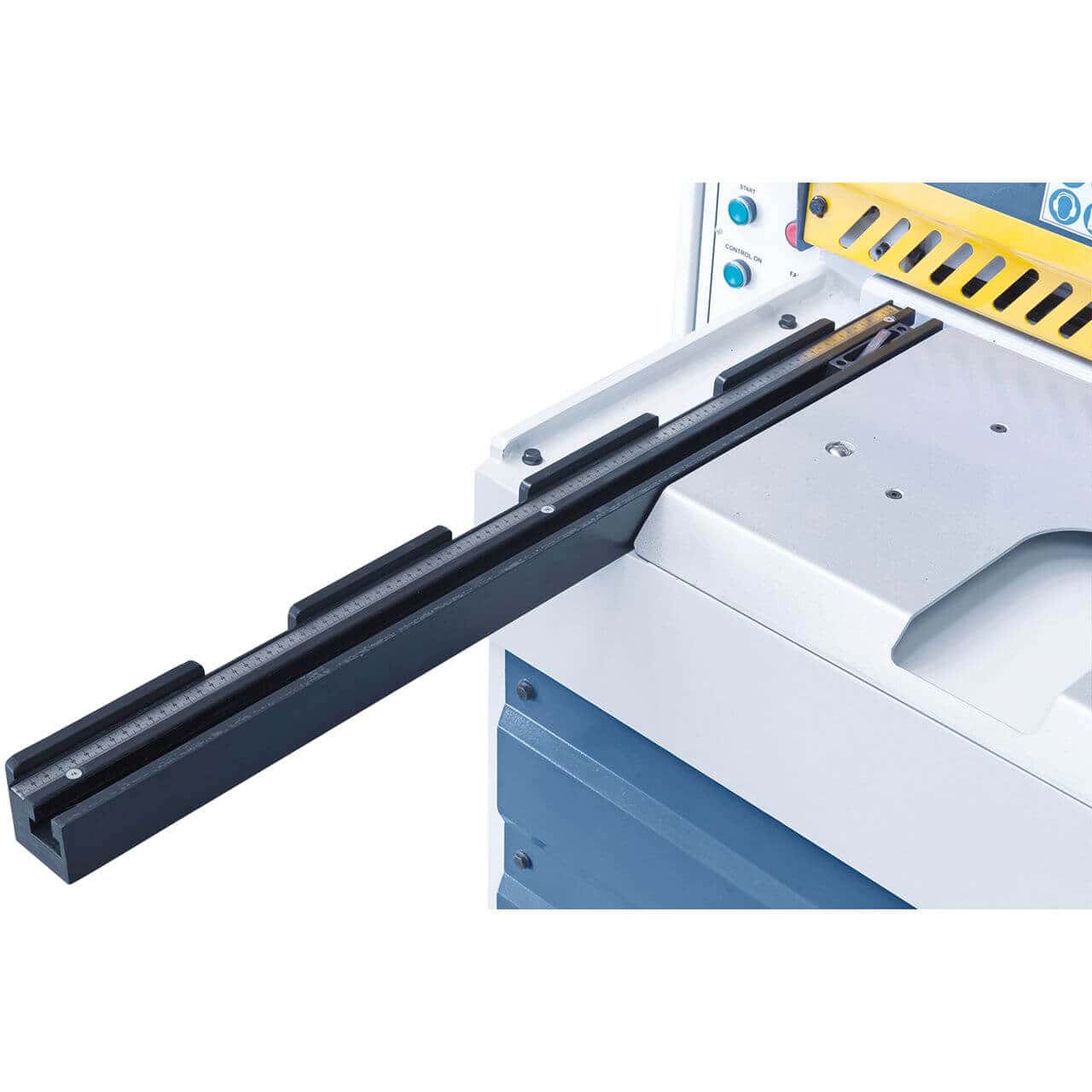

- Motorized rear stop, precise movement thanks to recirculating ball spindles

- Intuitive control panel with integrated controls

- Robust sheet steel construction for vibration-free operation

- Support table with right-angle stop on both sides

- High safety for the operator thanks to the protective cover and photocells on the back of the machine

- The 2-edge cutting blades made of quality steel ensure a clean, burr-free cut.

- Automatic press for fixing sheet metal

Standard accessories

- Lighting of the cutting area

- Numerically controlled motorized rear stop

- Front supports for slabs

- Side stops

- Protective sheet with photocells

- BRL 401.2 control unit

- Pneumatic sheet metal locking device

- Pedal with emergency stop

- Tool steel blades

technical specifications

| Cutting length | 2060 mm |

| Max. sheet metal thickness * | 3 mm |

| Cutting angle | 1st 30' |

| Races / min | 31 |

| Working height | 810 mm |

| Rear stop | 0 - 750 mm |

| Table width | 390 mm |

| Engine power | 4.0 kW |

| Length | 2600 mm |

| Depth | 2100 mm |

| Height | 1260 mm |

| Approximate weight | 1710 kg |

| * Material resistance 400 N/mm² |

Technical Specifications

Può tagliare lamiere fino a 2060 mm di lunghezza e 3 mm di spessore (acciaio 400 N/mm²), con precisione e senza bave.

È dotata di protezioni posteriori con fotocellule, pedale con arresto di emergenza e dispositivi di sicurezza integrati.

Garantisce stabilità durante il taglio di lamiere sottili o di grandi dimensioni, evitando deformazioni e migliorando la precisione.

Il backgauge è motorizzato e movimentato da viti a ricircolo di sfere, controllato dal sistema NC BRL 401.2 per regolazioni precise.

La cesoia pesa circa 1710 kg e viene fornita con imballo industriale protettivo, pronta per l’installazione in officina.

Può tagliare acciaio, alluminio, rame, ottone e altri metalli fino a 3 mm di spessore con alta precisione.