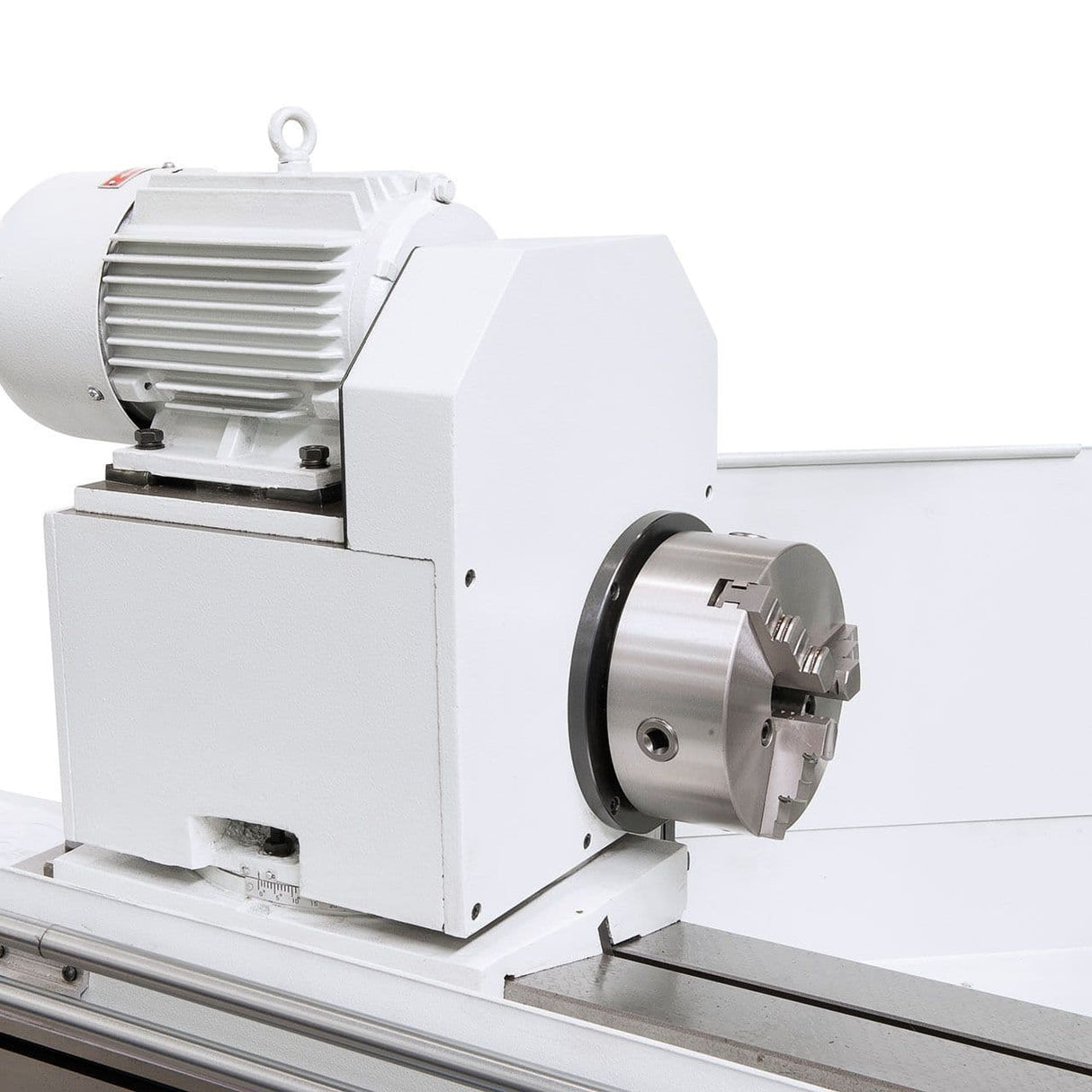

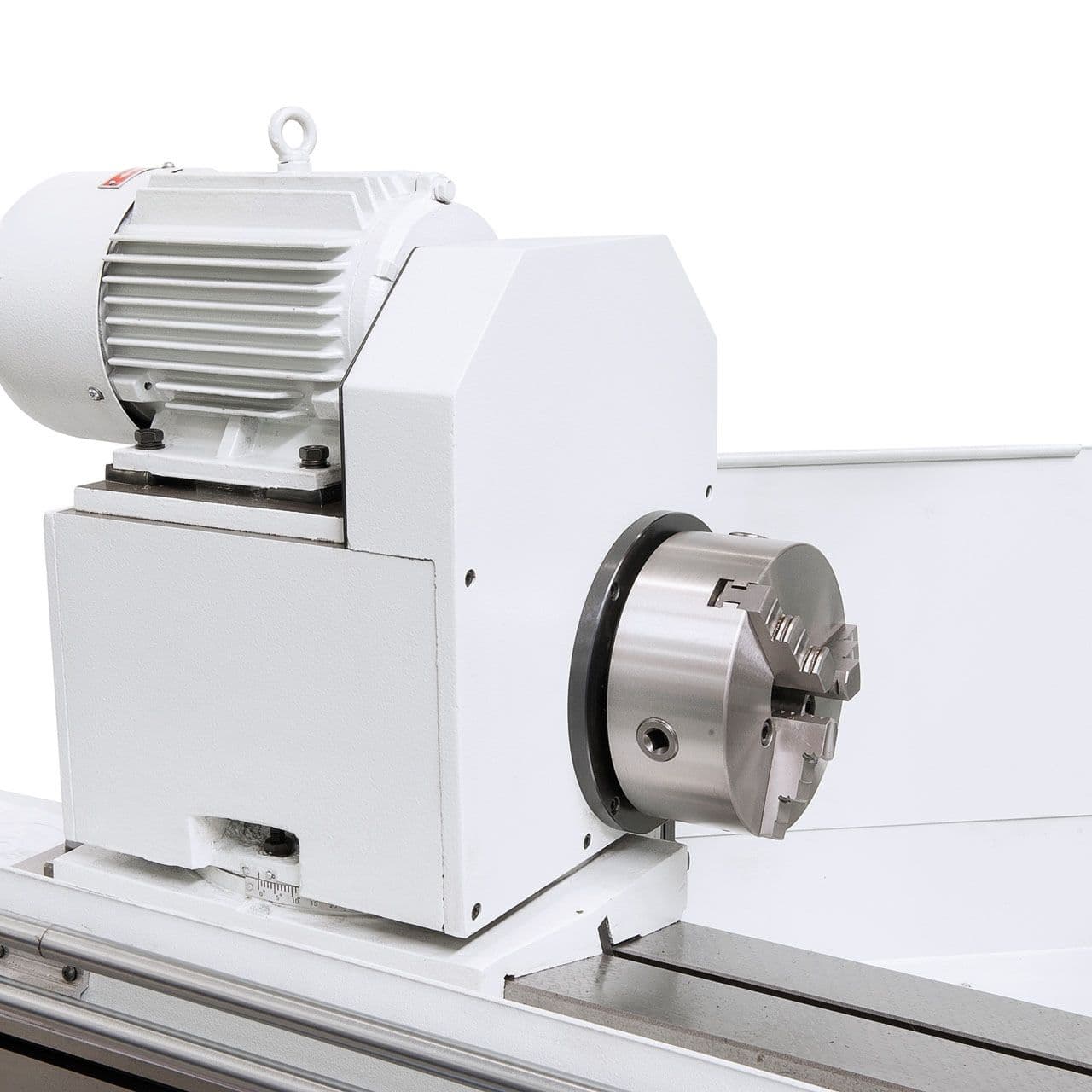

Universal cylindrical grinder URS 1500 N

Universal cylindrical grinder URS 1500 N is backordered and will ship as soon as it is back in stock.

Subscribe to our newsletter

Get the latest updates on all our new collections, sales, offers and product arrival dates.

-

Description

-

Technical Specifications

-

Product safety

-

Reviews

Description

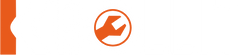

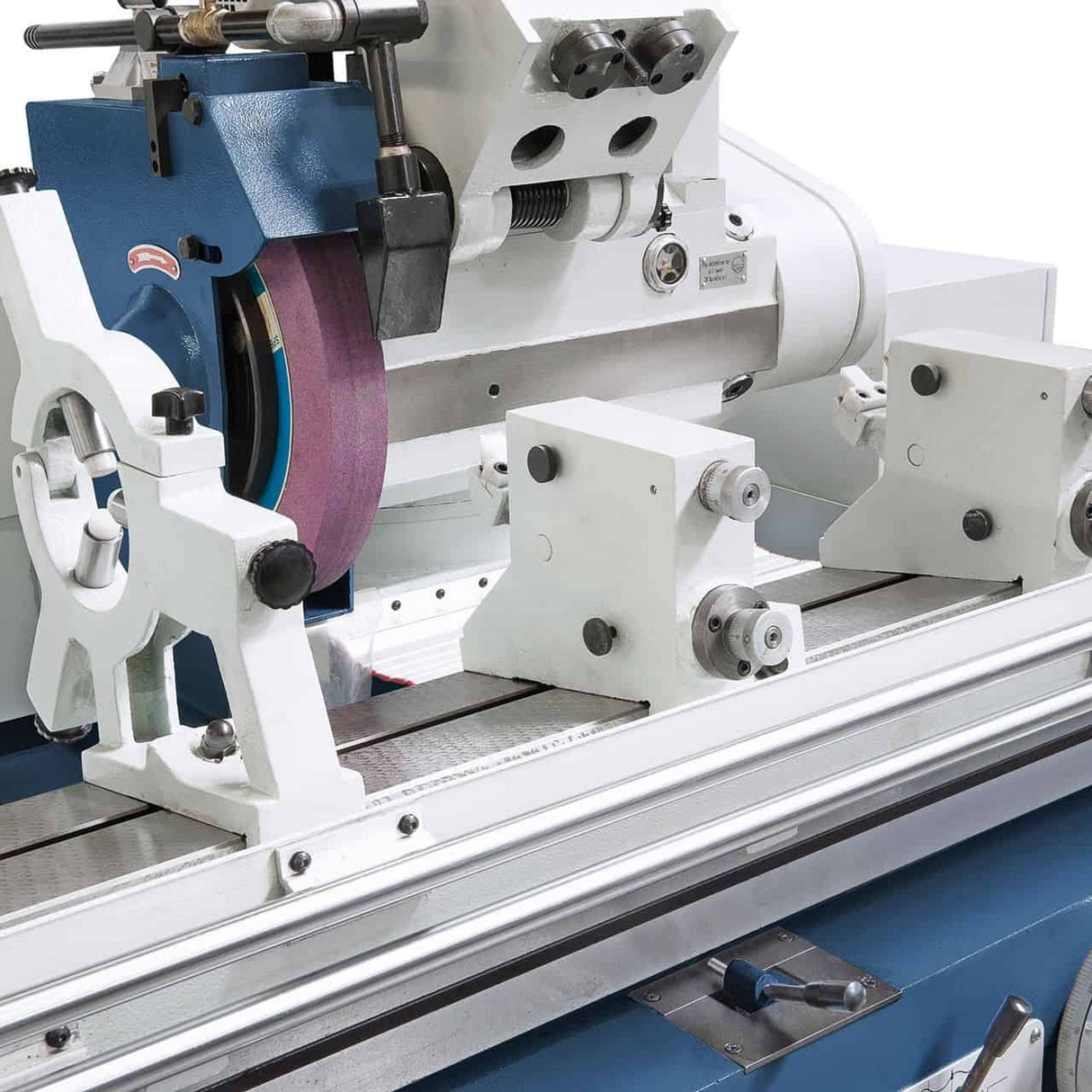

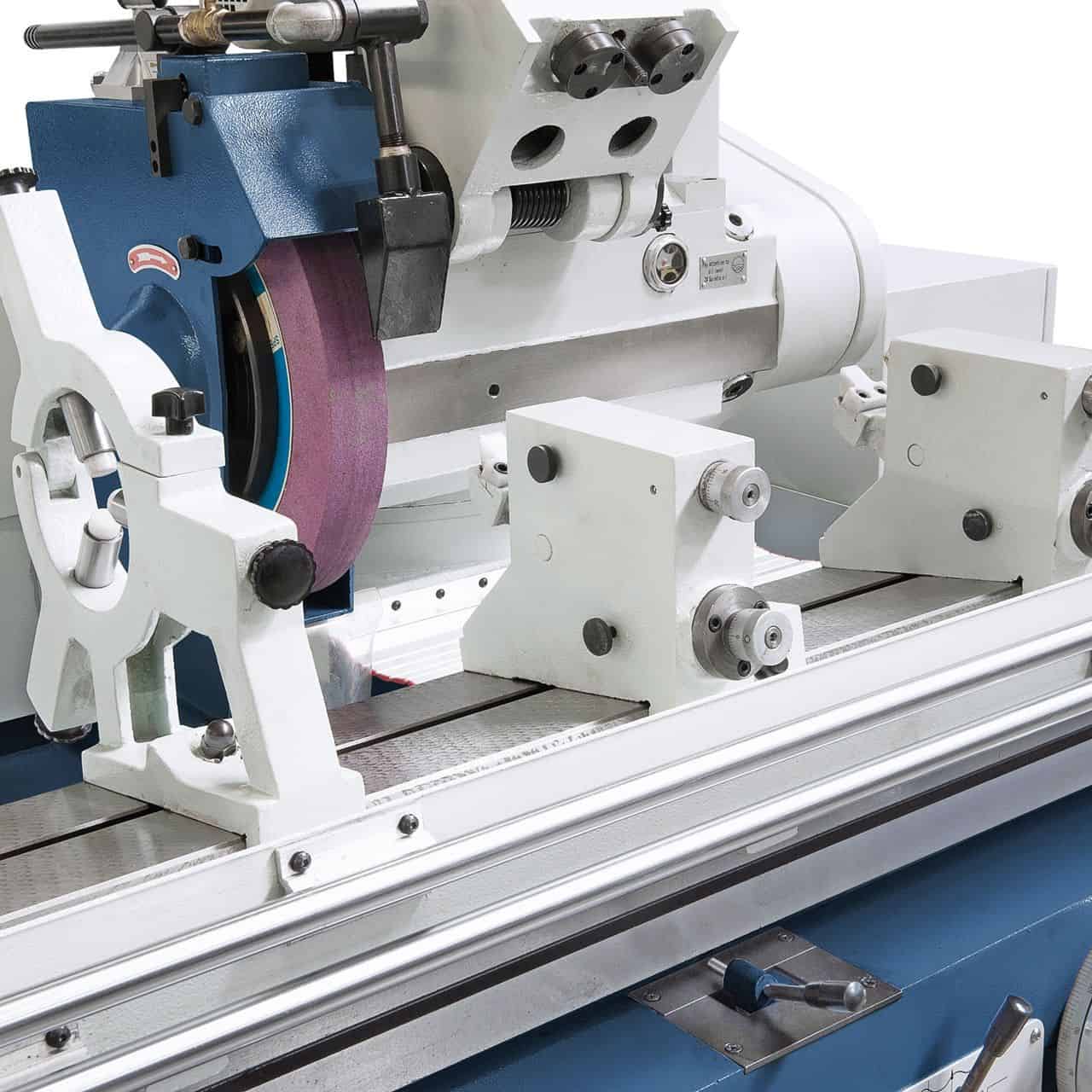

The URS 1500 N universal cylindrical grinder is suitable for external cylindrical grinding operations on workpieces up to 320 mm in diameter; the standard internal grinding attachment further expands its application range. This machine is primarily used in mechanical machining, toolmaking, and forming, as well as for finishing small series.

Property

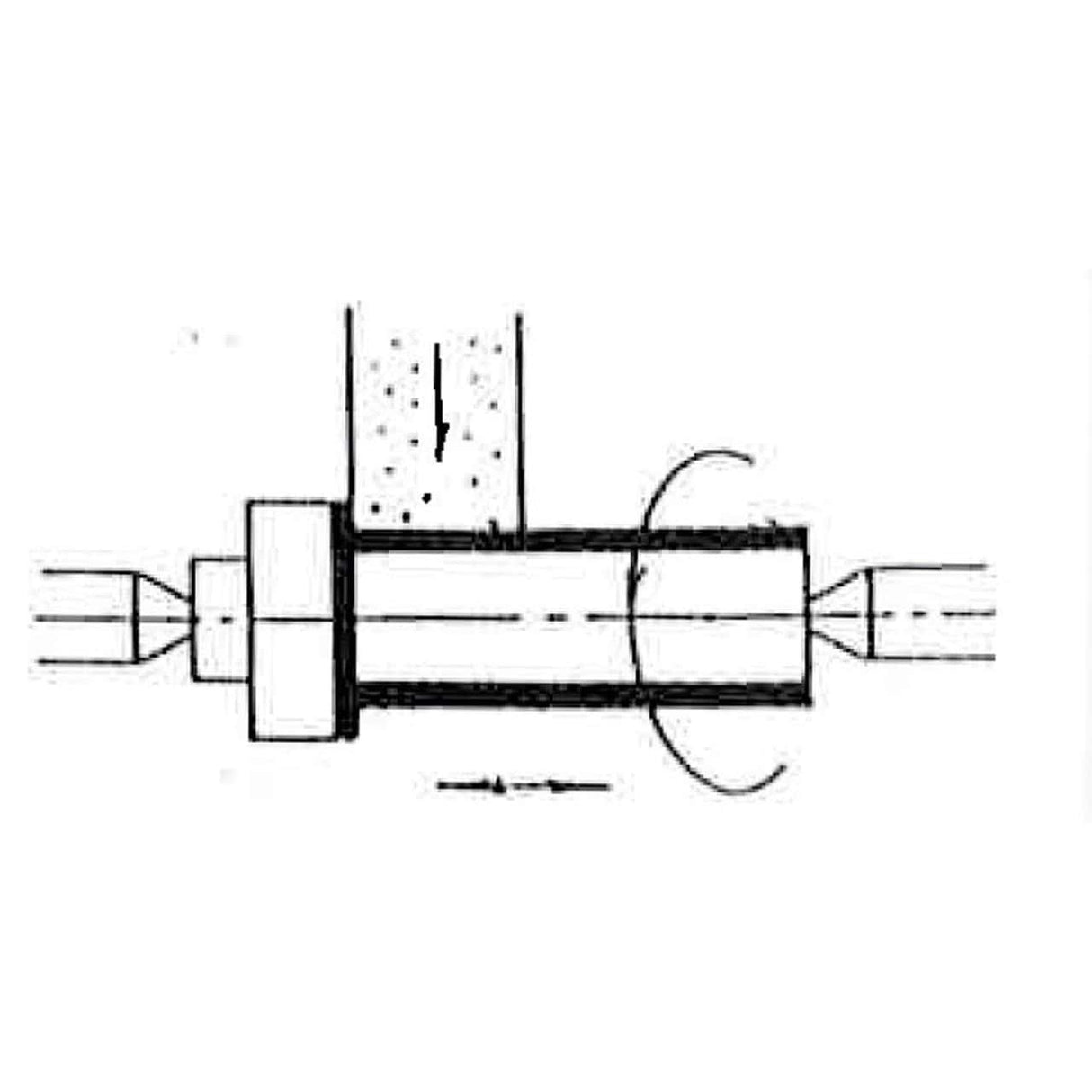

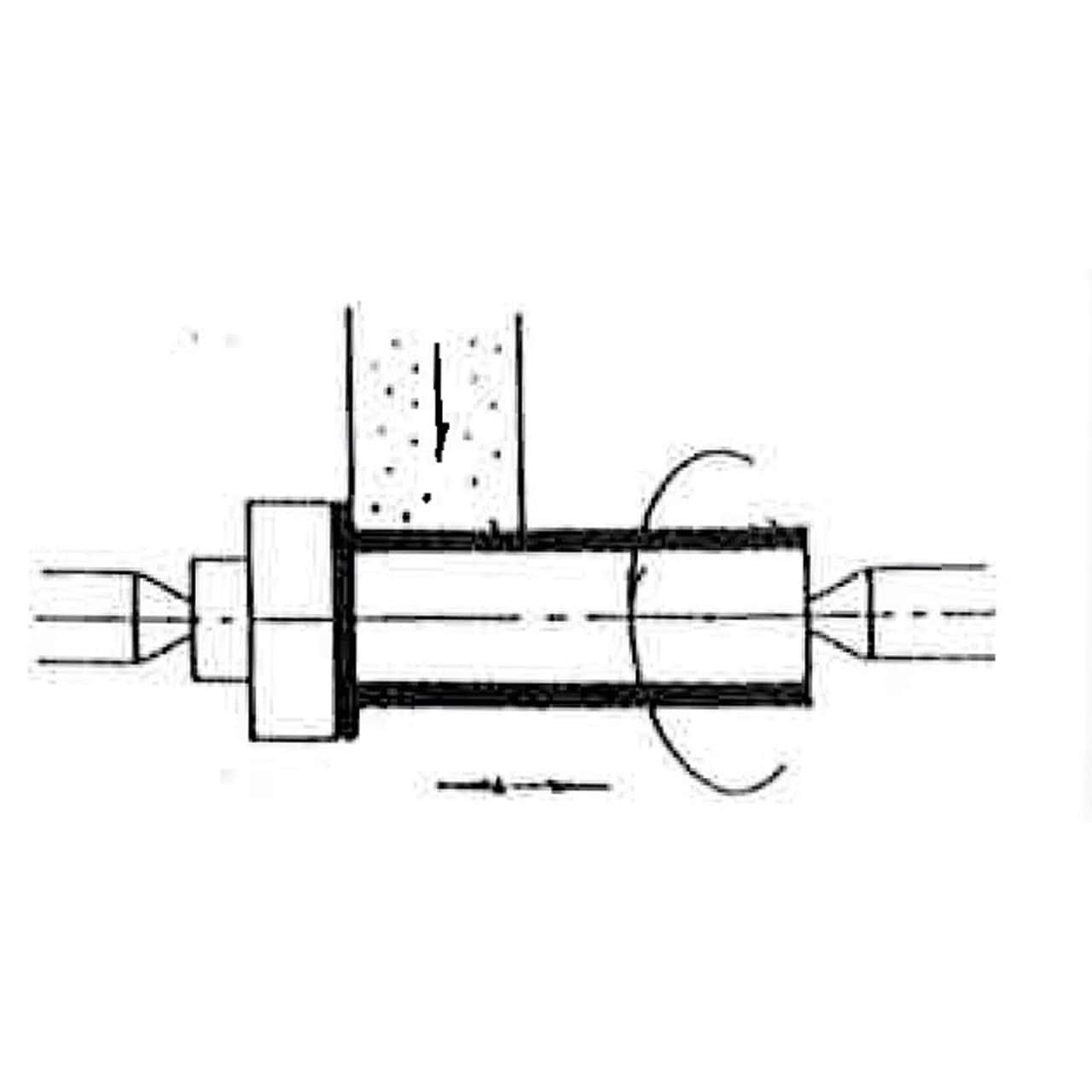

- The oil film between the bearing and the spindle minimizes vibrations: this way it is possible to obtain precision and a good surface finish.

- The large table can be tilted for conical grinding to two different positions and set to the desired position by means of a scale

- Precisely aligned spindle head and stable grinding spindle head for best possible machining results in various grinding processes

- Thanks to the strong ribs and large walls, the machine base is relatively insensitive to temperature changes and deformation.

- Grinding spindle mounted on both sides with tri-segmented and subsequently adjustable surface sliding bearings

- The main spindle is hydrodynamically supported, meaning a film of oil prevents contact between the bearing and the spindle.

- The longitudinal movement of the table takes place manually using a handwheel or automatically using the hydraulic power supply.

- Continuously adjustable feed rate with optionally preselectable waiting time at the end of each movement phase

- The grinding spindle head is reset hydraulically or by handwheel

- Precision hardened and hand-scraped guides in the x and y axes

- Longitudinal table guide and cross guide of the grinding spindle head, each with a V-shaped and flat guide

Standard accessories

- ES-12 H 2-Axis Position Display with LCD Display

- Grinding wheel boring

- Grinding wheel boring flange

- 3-jaw chuck diam. 200 mm

- 2 open lunettes

- Closed bezel

- Internal grinding device

- LED car light

- State of equilibrium

- Balancing spindle

- Frequency converter

- 2 central tips

- Blade plate

- Refrigeration system

- Mudflaps, front and rear

- Grinding wheel bore aligner

- Piece holder

- Control device

technical specifications

Distance between tips

1500 mm

Height of the tips

180 mm

External grinding dimensions

8 - 320 mm

Max. piece weight

150 kg

Internal grinding diameter with bezel

35 - 100 mm

Internal grinding diameter without bezel

30 - 100 mm

Max. internal grinding depth

125 mm

Max. table tilt area

from +3° to -6°

Max. longitudinal table movement.

1500 mm

Table advancement

0.1 - 4 m/min

Man. Table travel/knob turn

6 mm/turn

Spindle head

Continuous spindle speed

25 - 220 rpm

Spindle cone

MK 4

Working spindle tilt area

+90°

Grinding spindle head

Abrasive belt dimensions

400 x 50 x 203 mm

Grinding spindle speed

1670 rpm

Internal grinding spindle speed

10000 rpm

Grinding spindle tilt area

+/-30°

Grinding head stroke

180 mm

Scale division

0.0025 mm

Rapid stroke, hydraulic

50 mm/min

Tailstock

Spindle support

MK 4

Spindle stroke

30 mm

Engine power

Grinding spindle

5.5 kW

Work spindle

1.5 kW

Internal grinding spindle

1.1 kW

Machine dimensions (L x W x H)

4700 x 1900 x 1500 mm

Weight

4300 kg