-

Description

-

Technical Specifications

-

Product safety

-

Reviews

Description

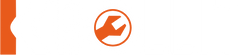

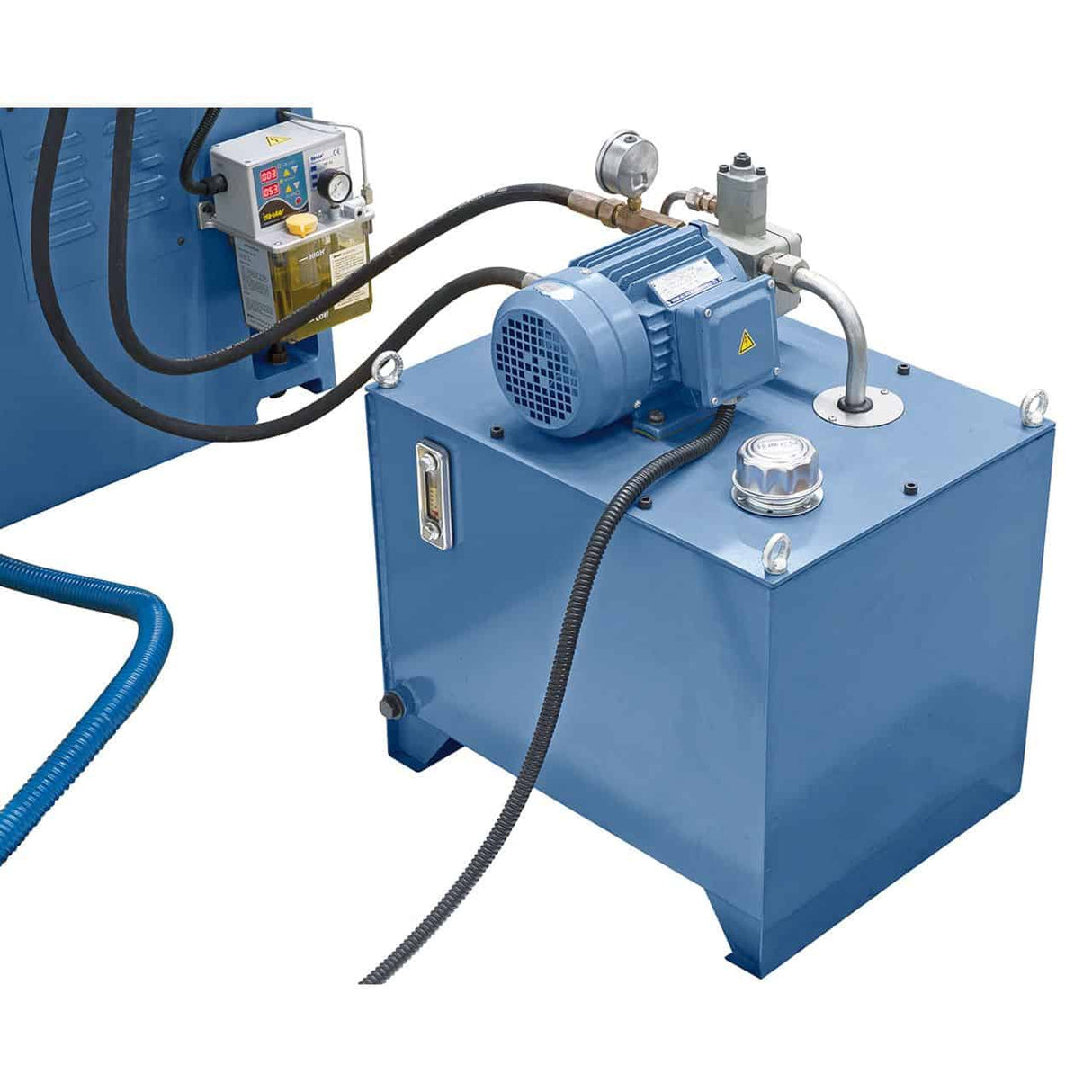

The hydraulic flat grinder BSG 2040 PLC impresses with its extensive standard equipment, which includes, for example: PC-controlled vertical approach, parallel extractor device with micrometric adjustment, magnetic plate with demagnetization device and digital 2-axis indicator.

Property

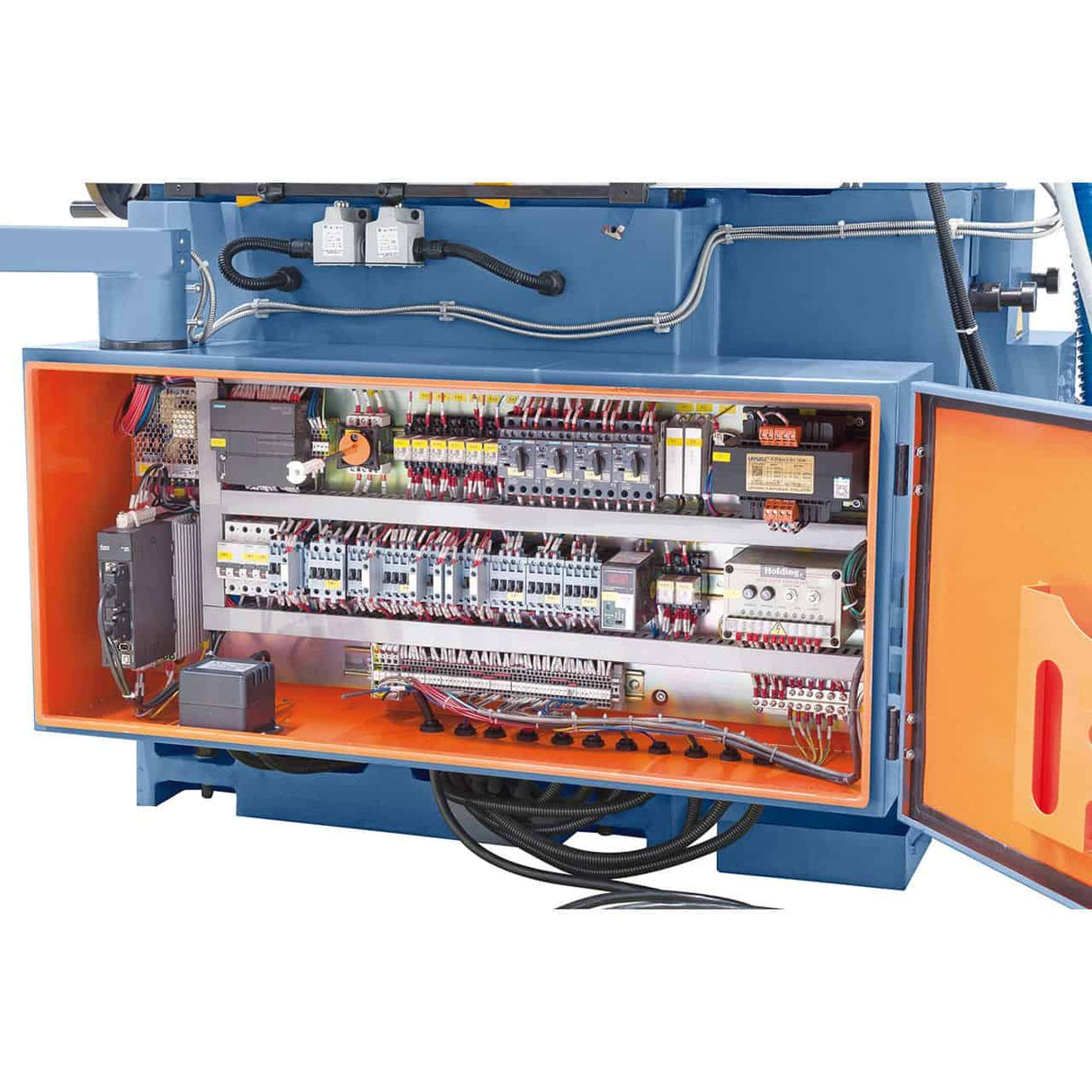

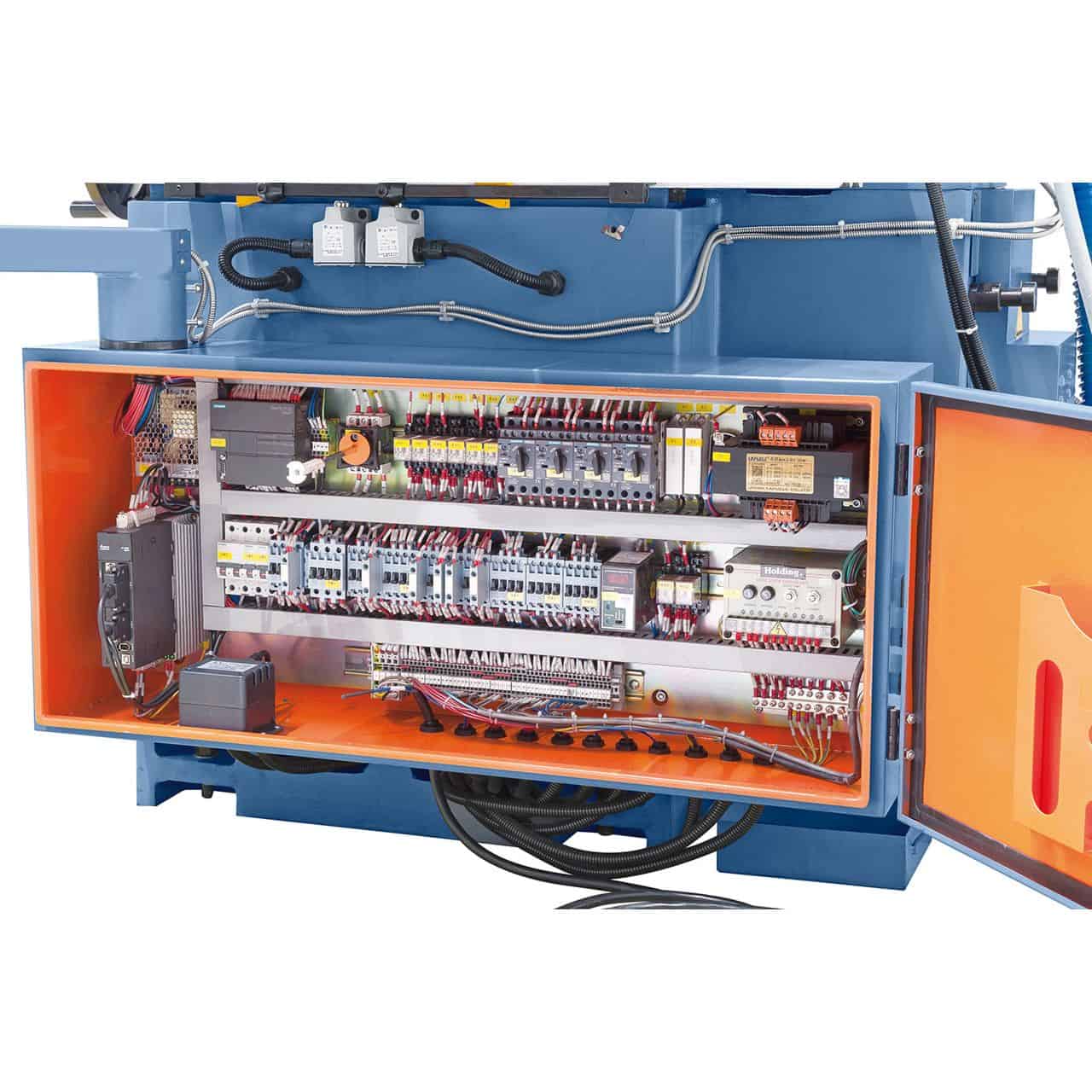

- PLC control unit for programming simple grinding cycles via touchscreen included

- The sophisticated hydraulic system guarantees smooth turning of the table even with high loads of the same

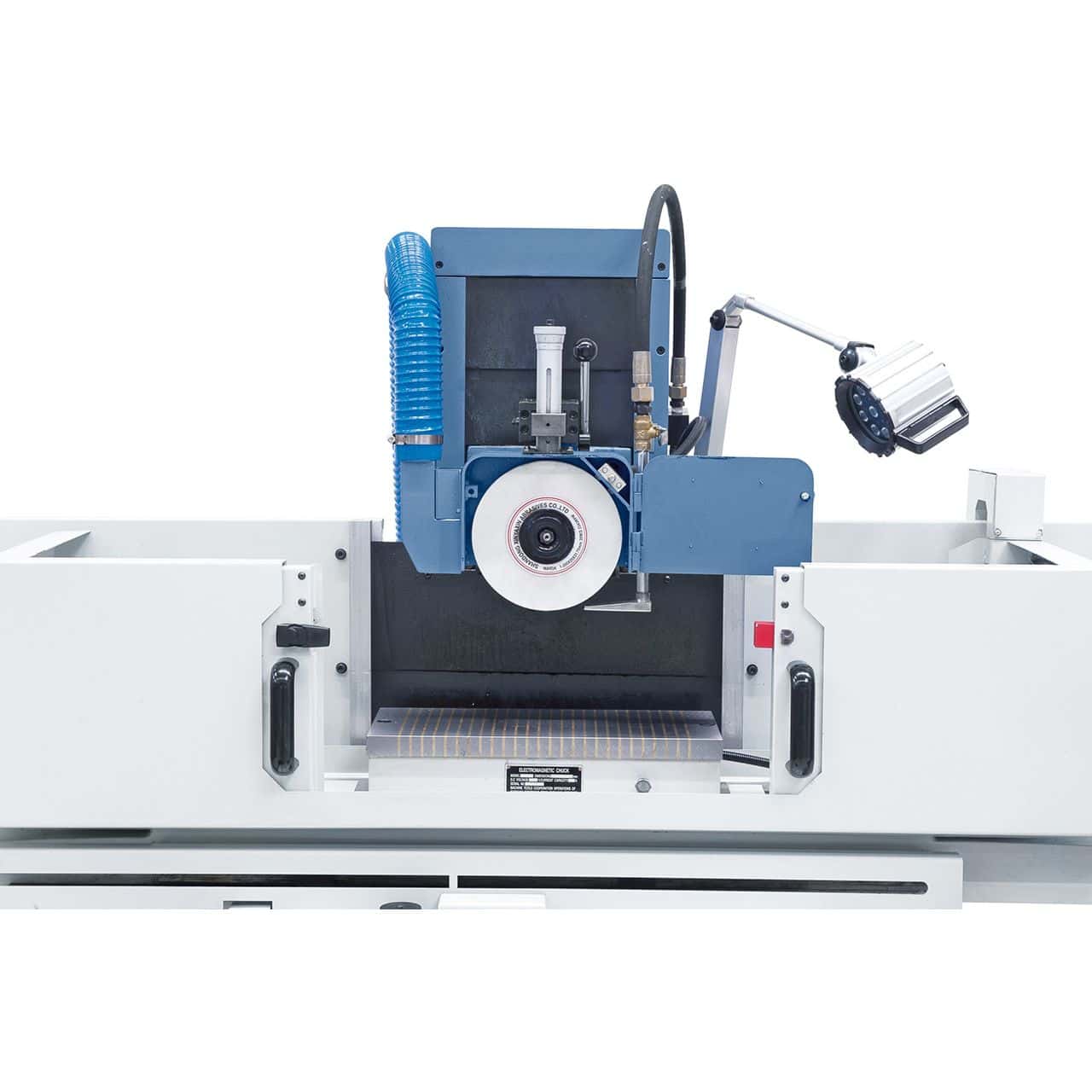

- The independent hydraulic unit with heat exchanger avoids vibrations and thermal stresses

- High stability thanks to strong ribs and large walls

- Reduced slip-stick effect thanks to plastic-coated counter-guides in the x- and y-axes

- Rapid approach to workpiece height, adjustable reconciliation stroke and flame suppression; automatic lifting after program end

- Special preloaded bearings without axial and radial play in the grinding spindle

- Automatic vertical feed with digital control and servomotor

- Adjustable longitudinal and transverse table movement by limit switches

- Longitudinal guide V-flat table, transversal guide double-V table

Standard accessories

- ES-12 H 2-axis position display with LCD display

- Siemens SMART IE V3 panel with touch control

- Electronic knob

- Grinding wheel boring

- Disc flange

- LED work light

- Magnetic clamping plate

- Balancing support

- Balance shaft

- Protective covers

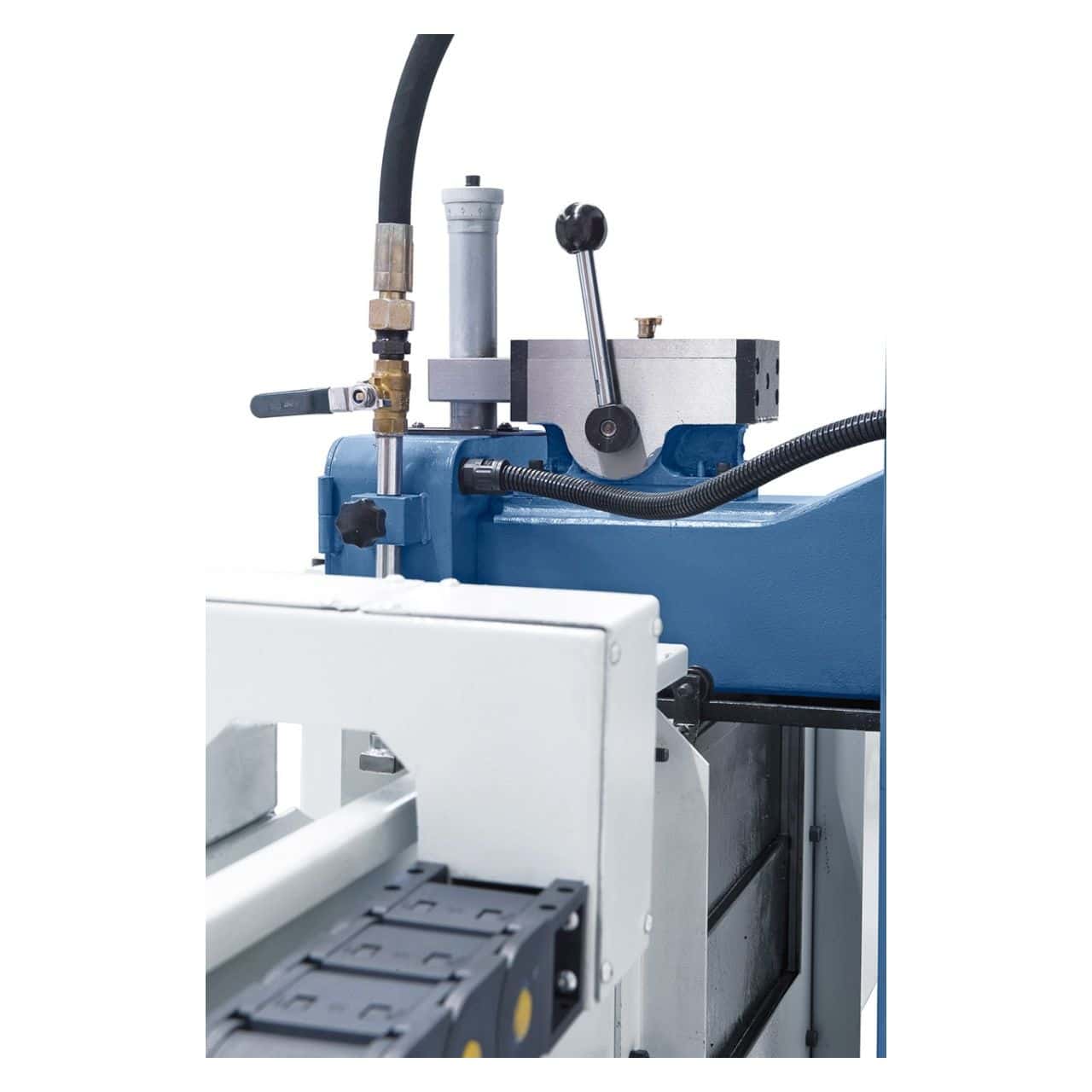

- Parallel grinding device

- Degaussing device

- Refrigeration system

- Diamond extractor

- Machine feet

- Central lubrication

- Control device

technical specifications

| Table clamping surface | 200 x 500 mm |

| Number of T-slots / width | 1 / 14 mm |

| Electronic magnetic clamping plate | 200 x 460 mm |

| Maximum travel, longitudinal | 560 mm |

| Maximum travel, transverse | 240 mm |

| Distance spindle center / table max. | 450 mm |

| Max. piece weight* | 180 kg |

| Grinding wheel boring | 200 x 20 x 31.75 mm |

| Table speed, hydraulic | 7 - 25 m/min |

| Transverse adjustment | |

| Automatic, transversal approach | 0.5 - 8 mm / stroke |

| Rapid, transverse run | 990 mm/min |

| Transverse approach per turn of the knob. | 4 mm/turn |

| Scale division on the flyer | 0.02 mm |

| Vertical approach | |

| Manual setup | 0.005 / 0.01 / 0.02 / 0.03 / 0.04 / 0.05 mm |

| Rapid, vertical run | 480 mm/min |

| Vertical approach per turn of the knob | 2 mm/turn |

| Scale division on the flyer | 0.005 mm |

| Grinding spindle motor | 2.2 kW |

| Spindle speed | 2850 rpm |

| Hydraulic pump motor | 0.75 kW |

| Vertical feed motor | 0.5 kW |

| Length | 2160 mm |

| Depth | 1650 mm |

| Height | 1840 mm |

| Weight approx. | 1640 kg |

| * with magnetic clamping plate |

Technical Specifications

È adatta alla rettifica di precisione di superfici piane su pezzi fino a 180 kg, con cicli programmabili via Siemens PLC touch.

Permette di programmare e memorizzare cicli di rettifica semplici, con interfaccia touchscreen intuitiva e veloce da usare.

Tavola 200x500 mm, corsa longitudinale 560 mm, trasversale 240 mm, altezza utile 450 mm, peso pezzo max. 180 kg con piastra magnetica.

È dotata di coperture protettive, dispositivo di demagnetizzazione, paraspruzzi, sistema di refrigerazione e lubrificazione centralizzata.

La macchina pesa circa 1640 kg, robusta e stabile, progettata per lavorazioni professionali e di precisione.

Puoi contattarci direttamente tramite la nostra pagina dedicata:

Contattaci