-

Description

-

Technical Specifications

-

Product safety

-

Reviews

Description

The FSM 2040 is a solidly constructed flat grinder with compact dimensions. Its ease of handling makes it ideal for schools, training courses, and tool and mold making.

Property

- Vibration-free spindle operation thanks to special high-quality bearings

- Hardened and ground precision linear guide for longitudinal table movement

- Transverse movement of the table by means of the precise double V guide

- All main construction groups such as fixed column, attachment and slides made of high-quality cast iron

- Fully equipped: 2-axis position indicators, permanent magnetic clamping plate and much more

- Indispensable for smaller parts and quick grinding processes

- Central lubrication for all guides

Standard accessories

- ES-12 H 2-axis position display with LCD display

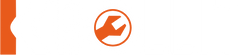

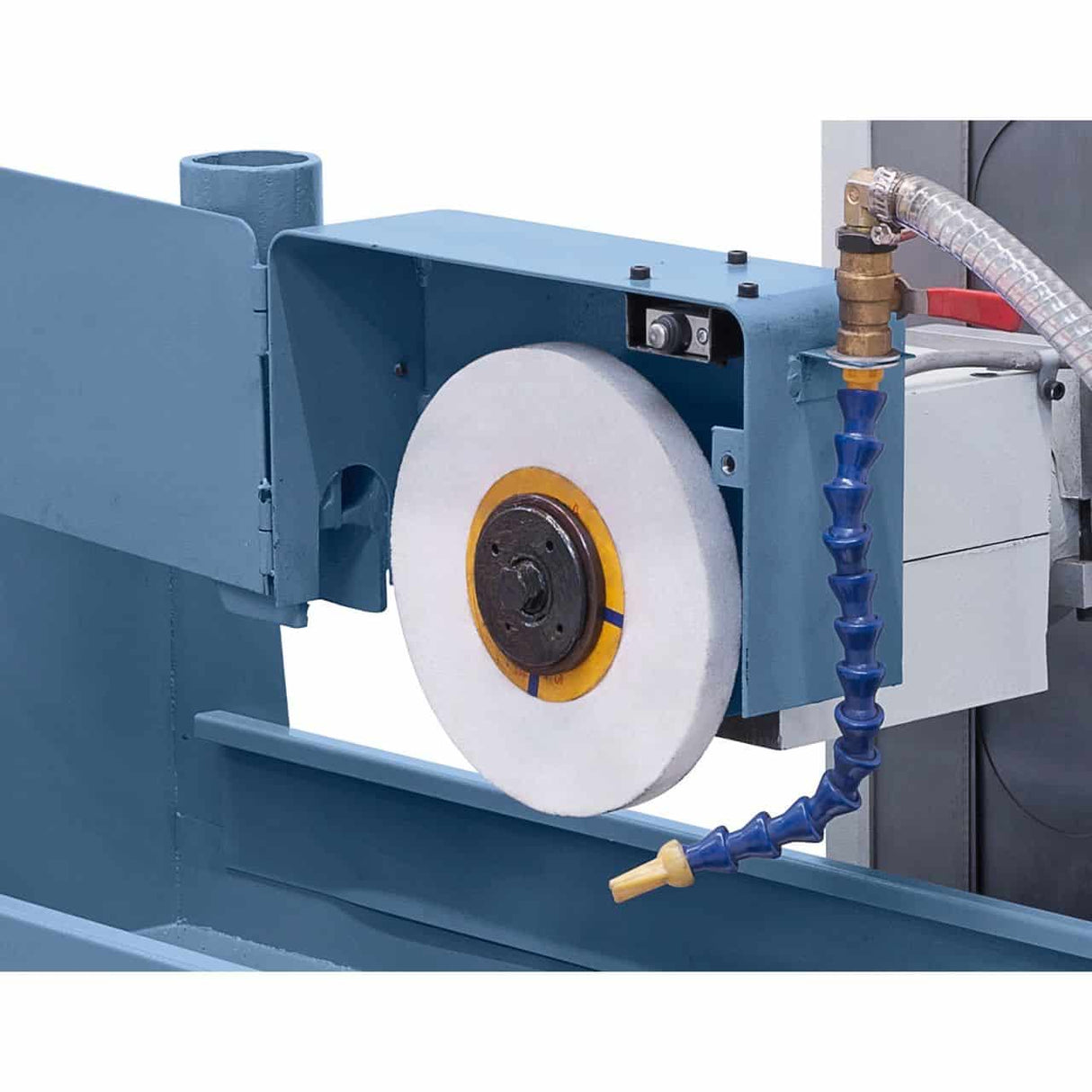

- Grinding wheel boring

- Disc flange

- LED work light

- Permanent magnetic clamping plate

- State of equilibrium

- Balance shaft

- Protective covers

- Degaussing device

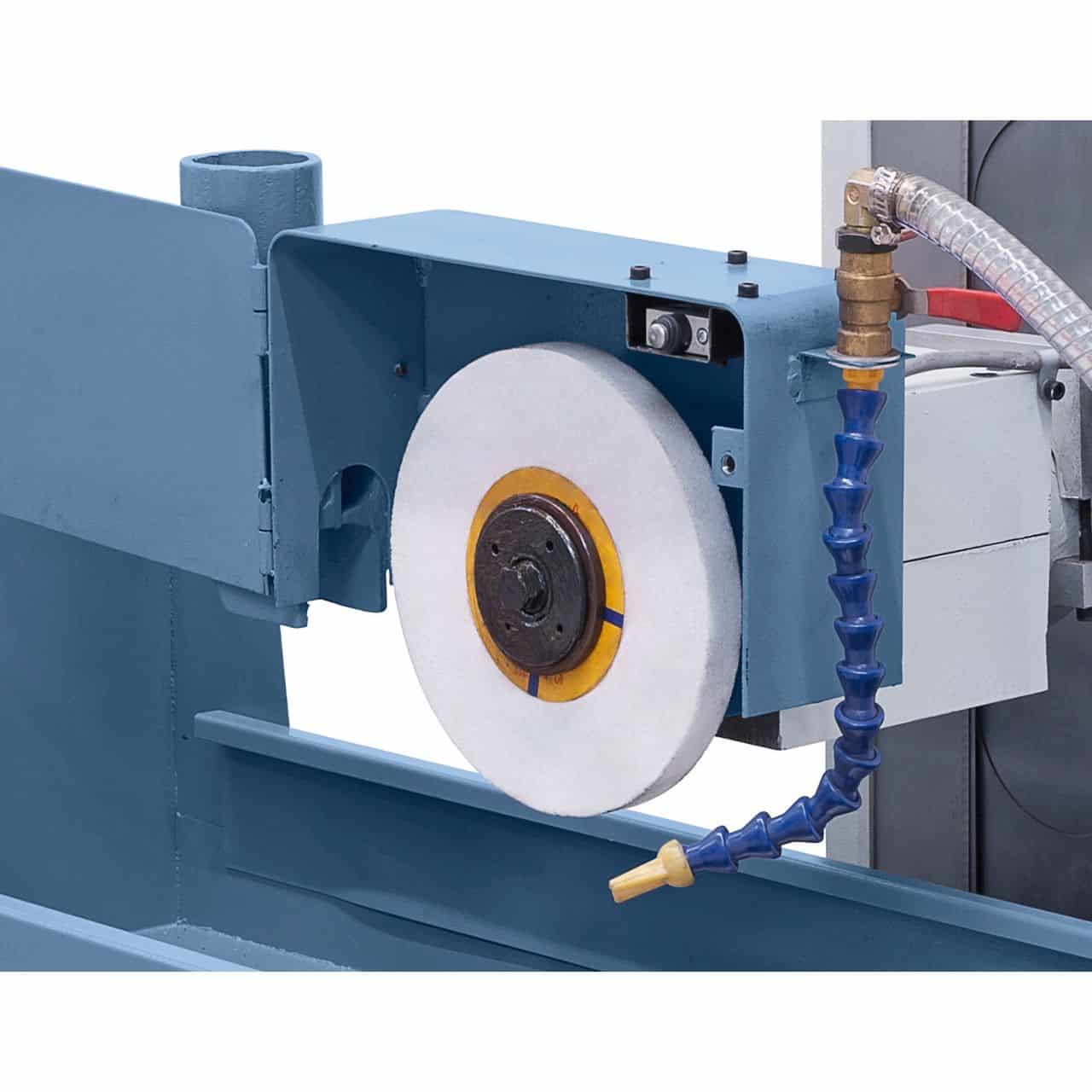

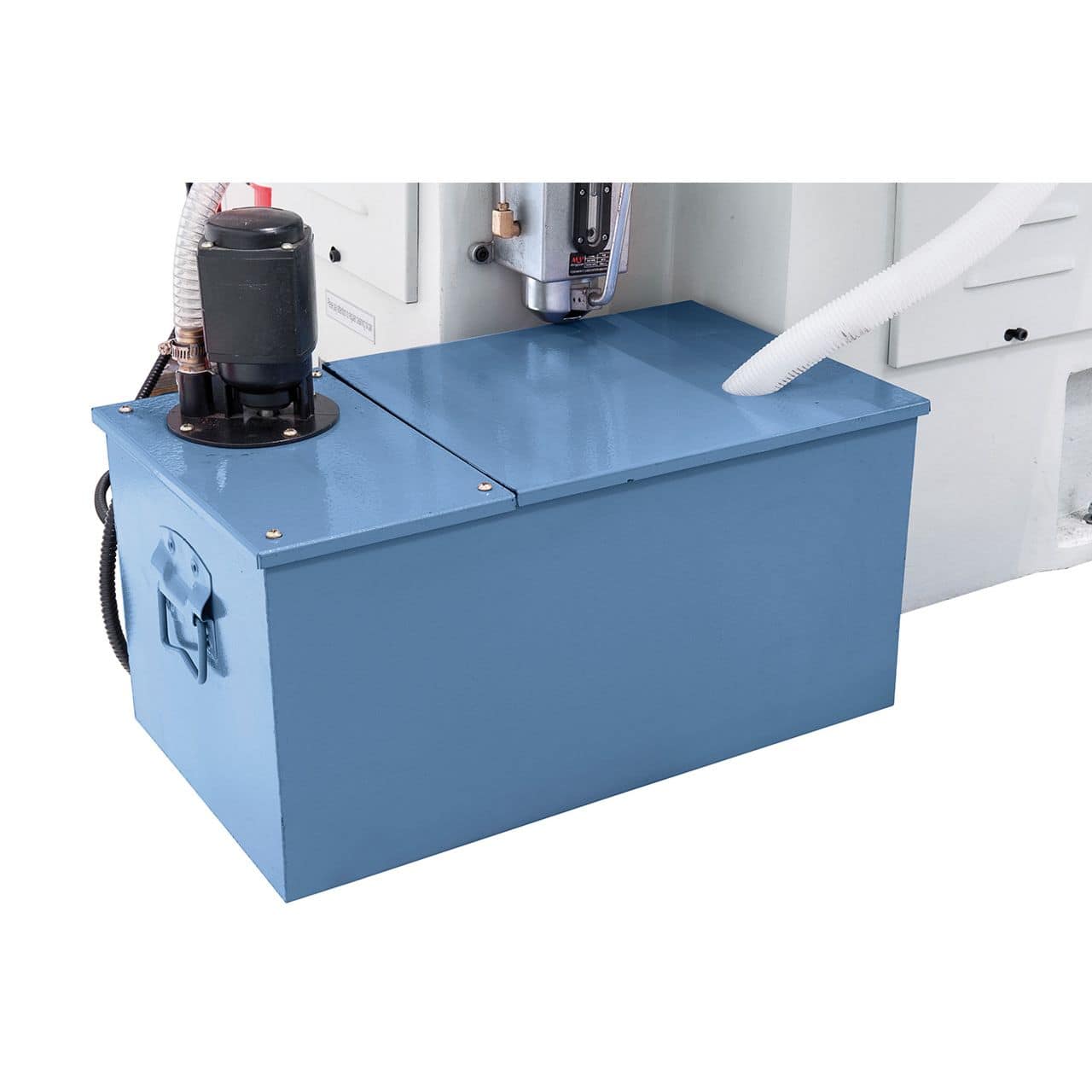

- Refrigeration system

- Diamond extractor

- Machine skates

- Central lubrication

- Control device

technical specifications

Table clamping surface |

500 x 210 mm |

Number of T-slots / width |

1 / 14 mm |

Permanent magnetic clamping plate |

200 x 400 mm |

Maximum travel, longitudinal |

530 mm |

Maximum travel, transverse |

220 mm |

Distance spindle center / table max. |

420 mm |

Grinding wheel boring |

200 x 20 x 31.75 mm |

| Table speed, electric |

3 – 20 m/min |

Transverse adjustment |

|

Table speed, electric |

0.1 – 2 m/min |

Transverse approach per turn of the knob |

2.5 mm |

Scale division on the flyer |

0.02 mm |

Vertical approach |

|

Vertical approach per turn of the knob |

1.25 mm |

Scale division on the flyer |

0.01 mm |

Grinding spindle motor |

1.5 kW |

Spindle speed |

2800 rpm |

Length |

1250 mm |

Depth |

1400 mm |

Height |

1730 mm |

Weight approx. |

750 kg |