TRM 750 tool milling machine incl. 3-axis digital display

TRM 750 tool milling machine incl. 3-axis digital display is backordered and will ship as soon as it is back in stock.

Delivery and Shipping

Delivery and Shipping

Add some general information about your delivery and shipping policies.

-

Description

-

Technical Specifications

-

Product safety

-

Reviews

Description

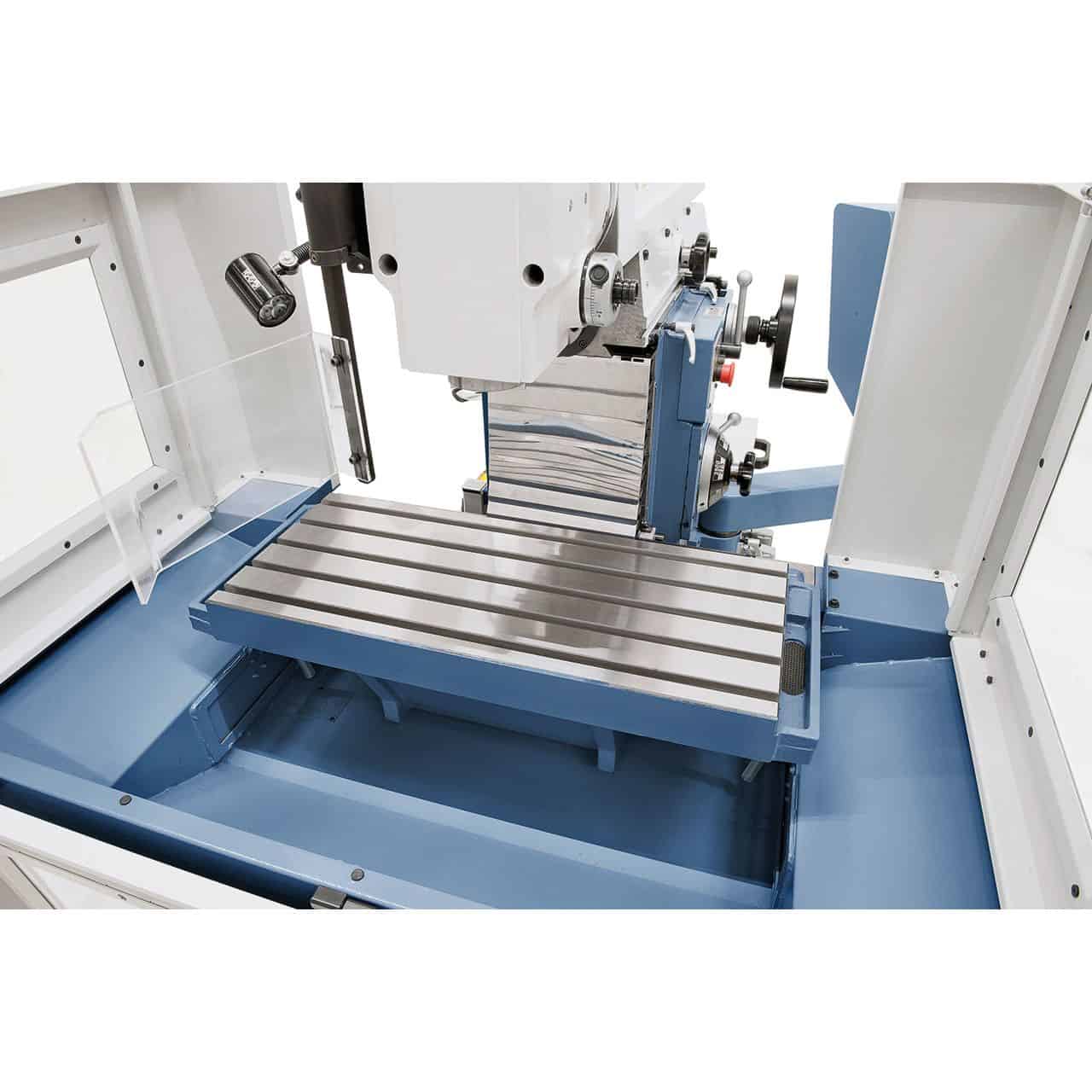

The TRM 750 universal milling machine is suitable for light to medium-duty milling. This model, even with its standard accessories, offers horizontal, vertical, and inclined milling capabilities. This model is primarily used in tool and mold making and model making, but is also frequently used in training centers.

Property

- Backlash-free preloaded rotary ball spindles in all 3 axes

- Equipped with central lubrication for the guides

- Equipped with manual, automatic and rapid traverse feeds in all 3 axes

- Vertical clamping surface with 2 T-slots for clamping the work table, universal tilting table or large workpieces

- Large dovetail guide in x, y and z axes

- Continuously adjustable feed speed via frequency converter

- The machine base with heavy cast iron valve guides ensures vibration-free and high-precision work.

- Economical processing of various materials through optimal adjustment of the freely selectable spindle speed and feed rates

- Essential machines for toolmaking, moldmaking, educational institutions, industry, model making, model making, etc.

Standard accessories

- ES-12 H 3-Axis Position Display with LCD Display

- LED car light

- Refrigeration system

- Feed for the x, y and z axes

- Horizontal external support

- Table casing

- 3-axis ball screws

- M 16 clamping chuck

- Power plant lubrication

- Delta frequency inverter for power supply

- Slat protection cover

- Long drilling chuck ISO 40/27 mm

- ISO 40 / MK 3 adapter

- Reduction socket MK 3 / 2

- Reduction socket MK 3 / 1

- ISO 40 collet chuck with collets 5 - 25 mm (7 pcs.)

- Control device

technical specifications

Table dimensions |

750 x 320 mm |

Vertical clamping surface |

825 x 225 mm |

Longitudinal travel (x) |

310 (350*) mm |

Transverse travel (y) |

160 (200*) mm |

Vertical travel (z) |

295 (335*) mm |

Table load |

280 kg |

Vertical milling head |

|

Spindle speed |

(12) 50 - 2000 rpm |

Spindle attachment |

ISO 40 |

Hole stroke |

120 mm |

Max. arm length |

485 mm |

Spindle/table distance |

65 - 405 mm |

Spindle head tilt area |

from -90° to +90° |

Horizontal milling head |

|

Spindle speed |

(12) 50 - 2000 rpm |

Spindle attachment |

ISO 40 |

Distance between horizontal spindle and table |

35 - 370 mm |

Feed rate |

|

x-axis |

8 - 450 mm/min |

y-axis |

8 - 450 mm/min |

Z-axis |

8 - 450 mm/min |

Rapid travel (x / y / z) |

720 mm/min |

| T-slots (number, width, spacing) |

5 / 14 mm / 63 mm |

T-slots vertical table (num. / width / dist.) |

2 / 14 mm / 126 mm |

Advance motor |

0.375 kW |

Main engine |

2.2 kW |

Machine dimensions (L x W x H) |

1450 x 1230 x 1920 mm |

Weight approx. |

1280 kg |

* manual