UWF 90 V universal milling machine with pneumatic tool clamping

UWF 90 V universal milling machine with pneumatic tool clamping is backordered and will ship as soon as it is back in stock.

Subscribe to our newsletter

Get the latest updates on all our new collections, sales, offers and product arrival dates.

-

Description

-

Technical Specifications

-

Product safety

-

Reviews

Description

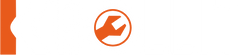

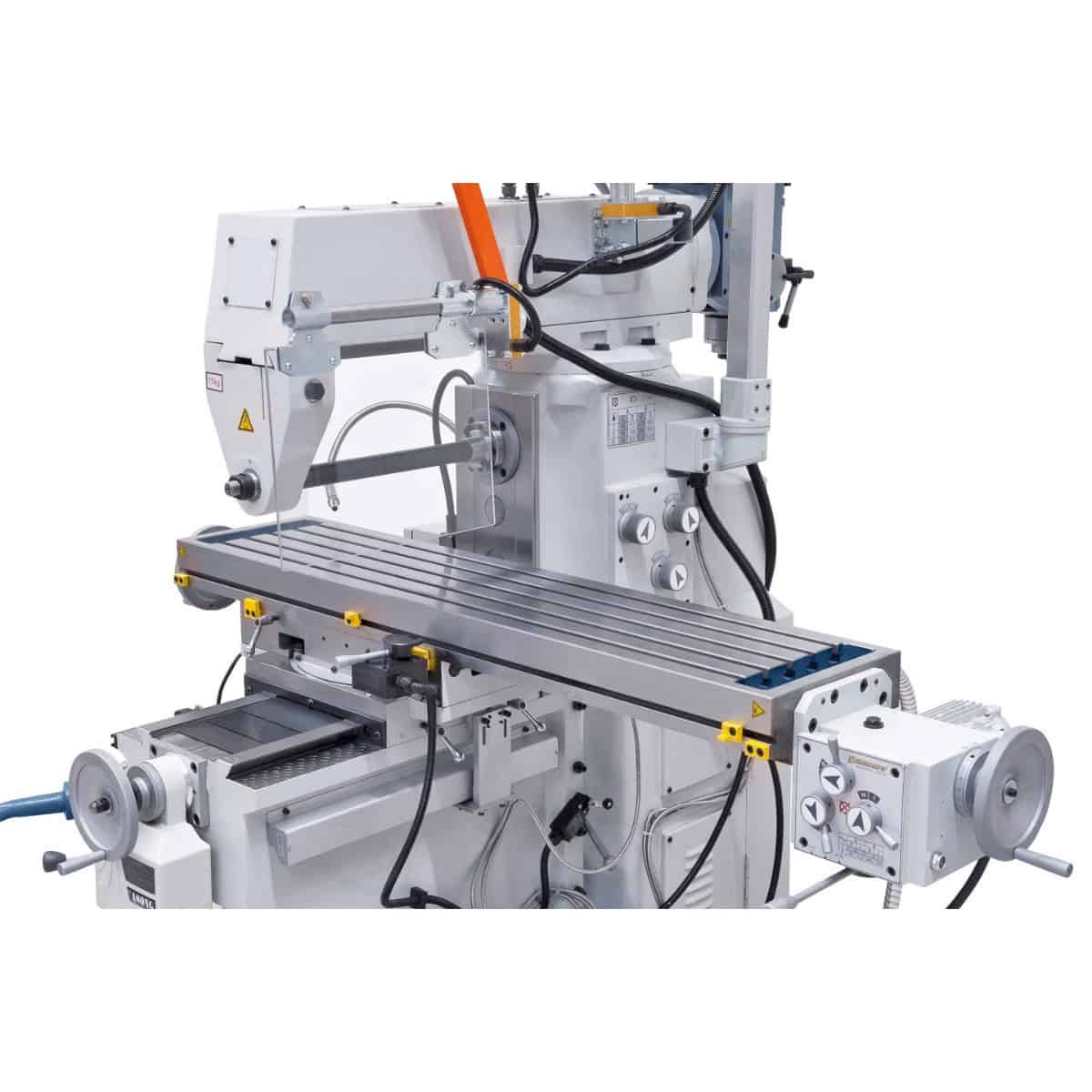

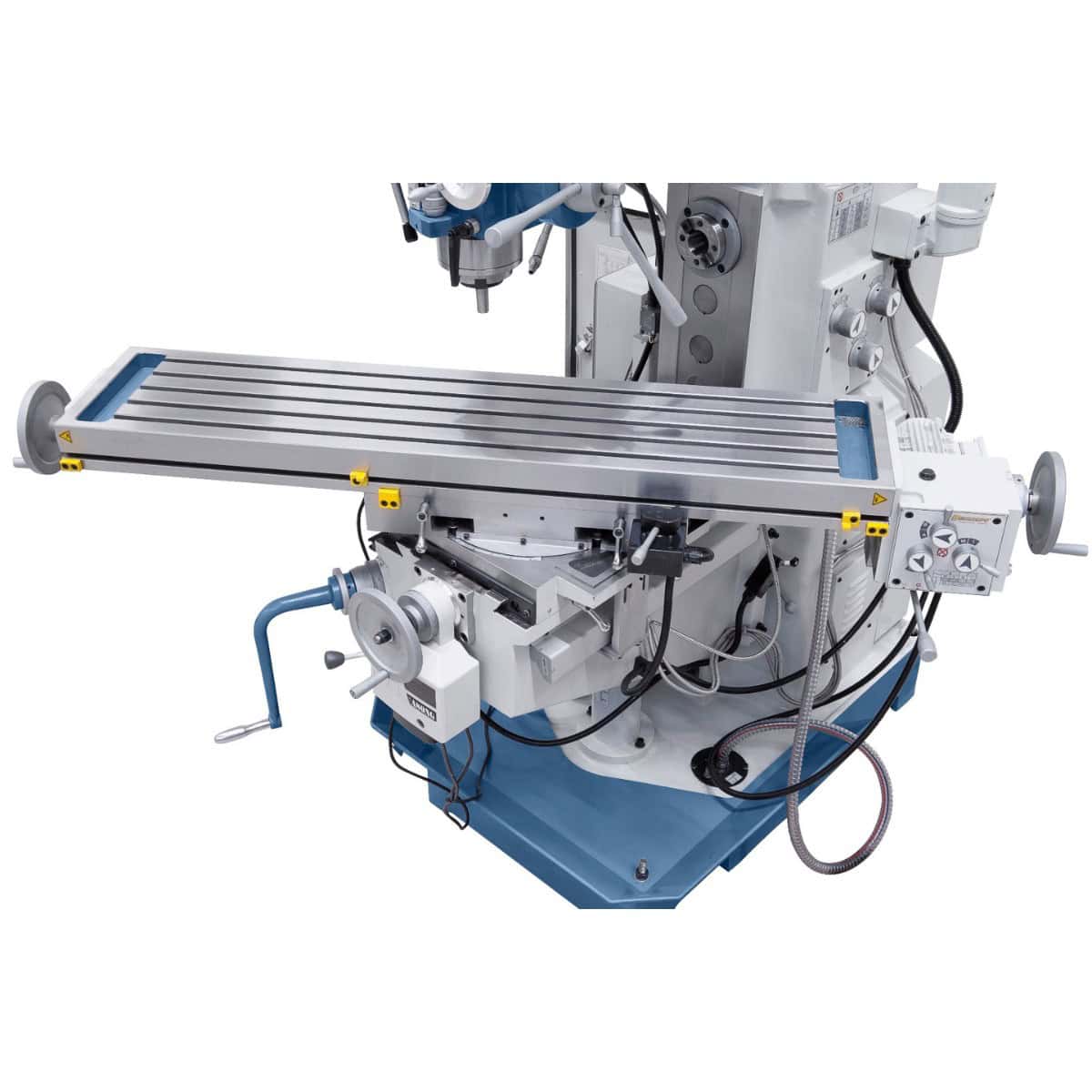

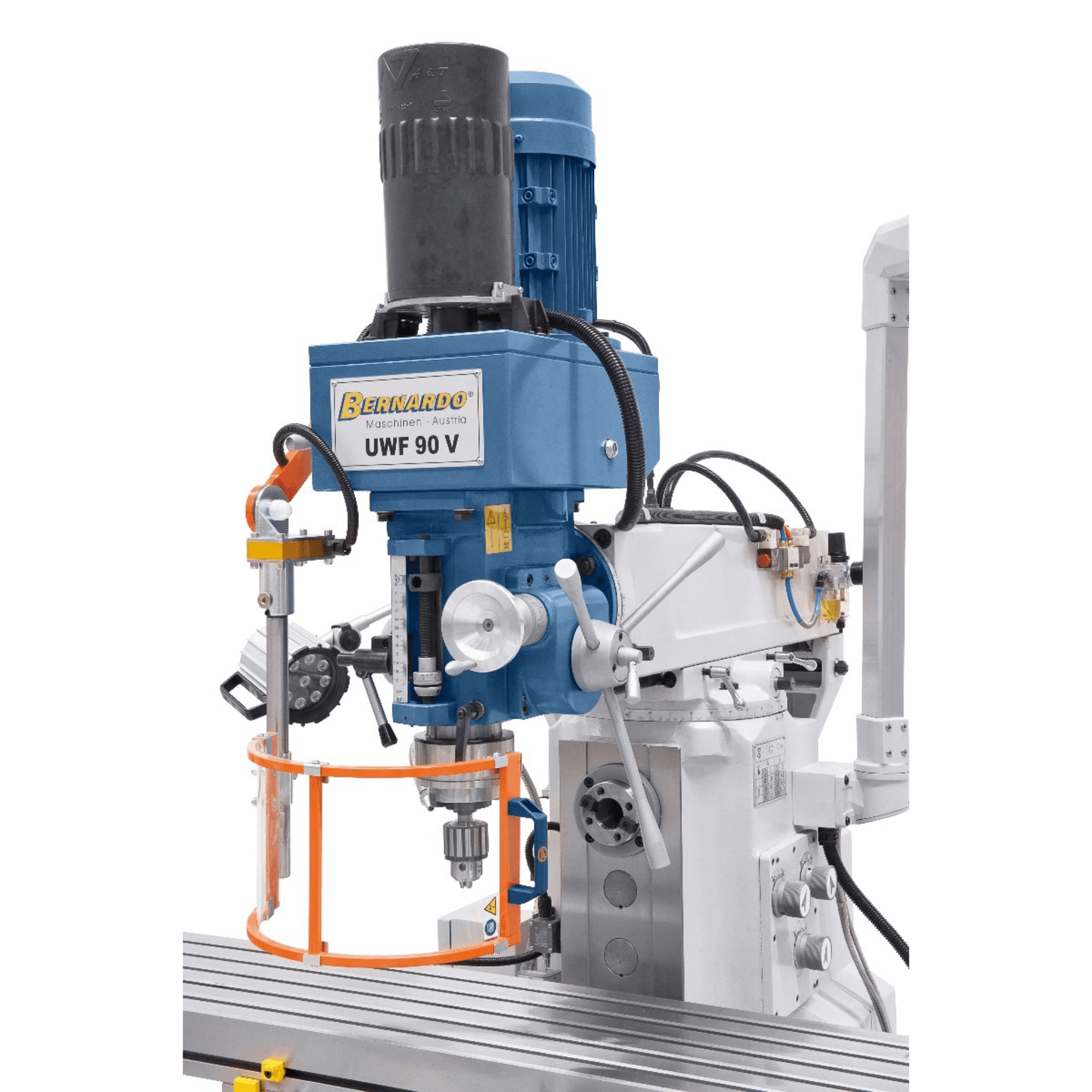

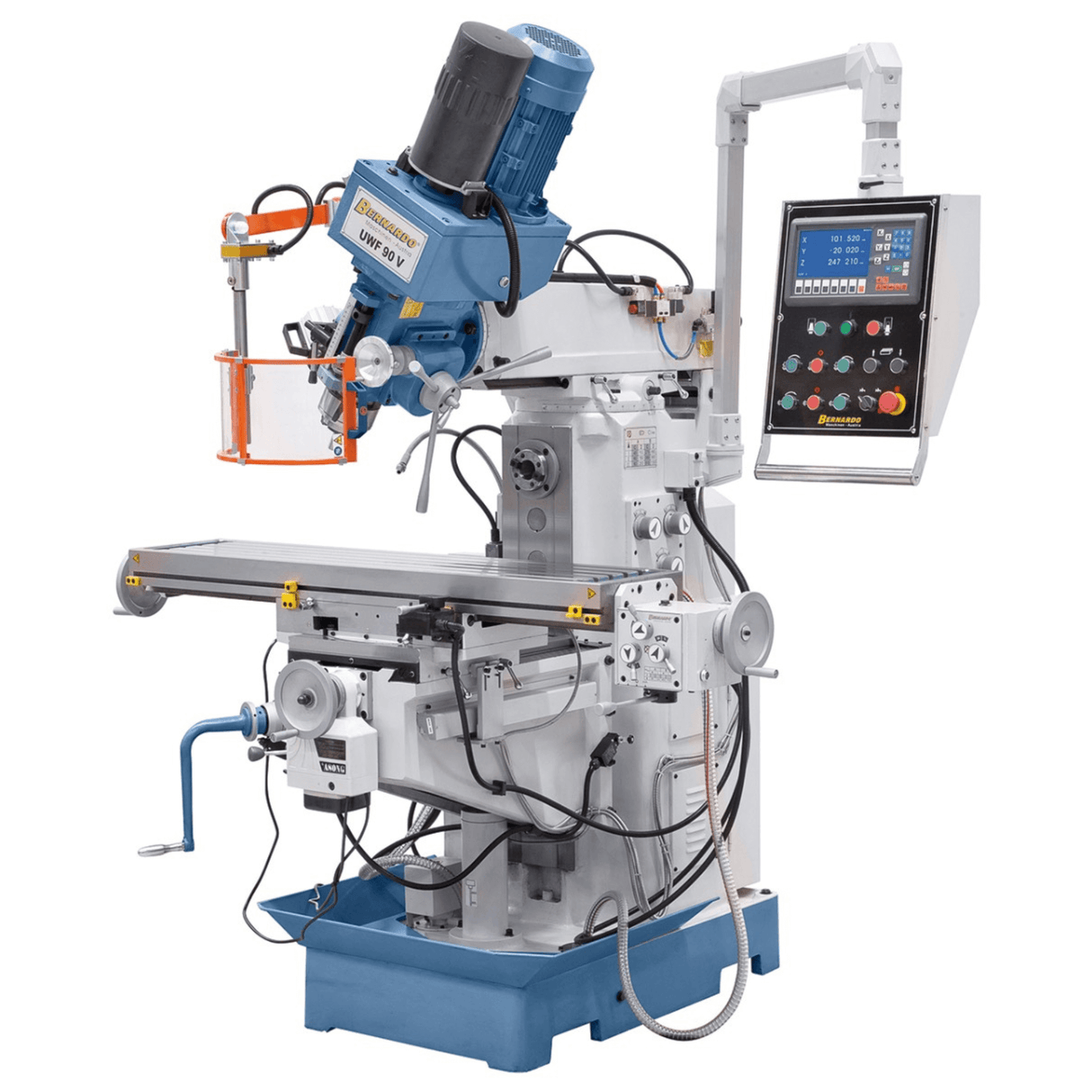

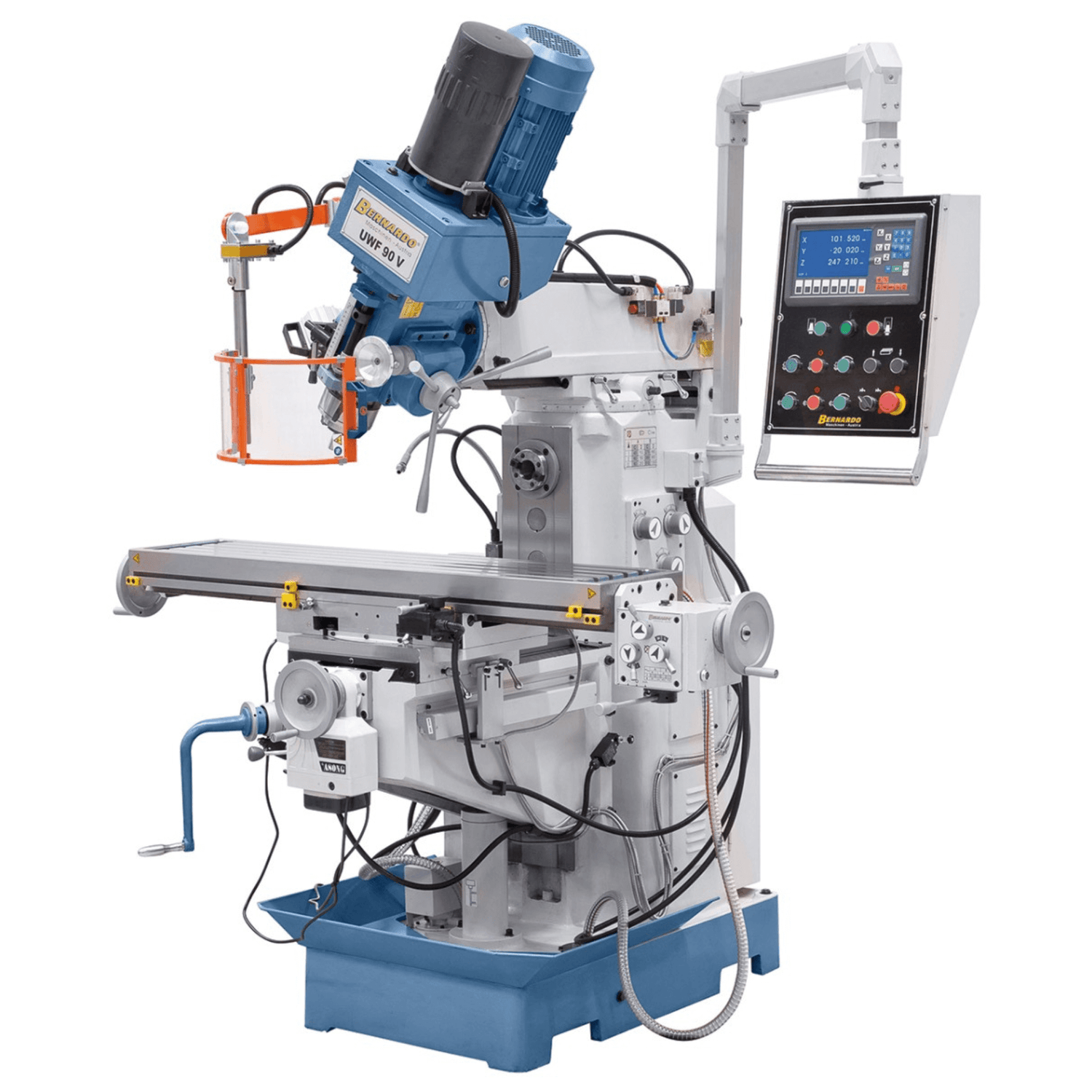

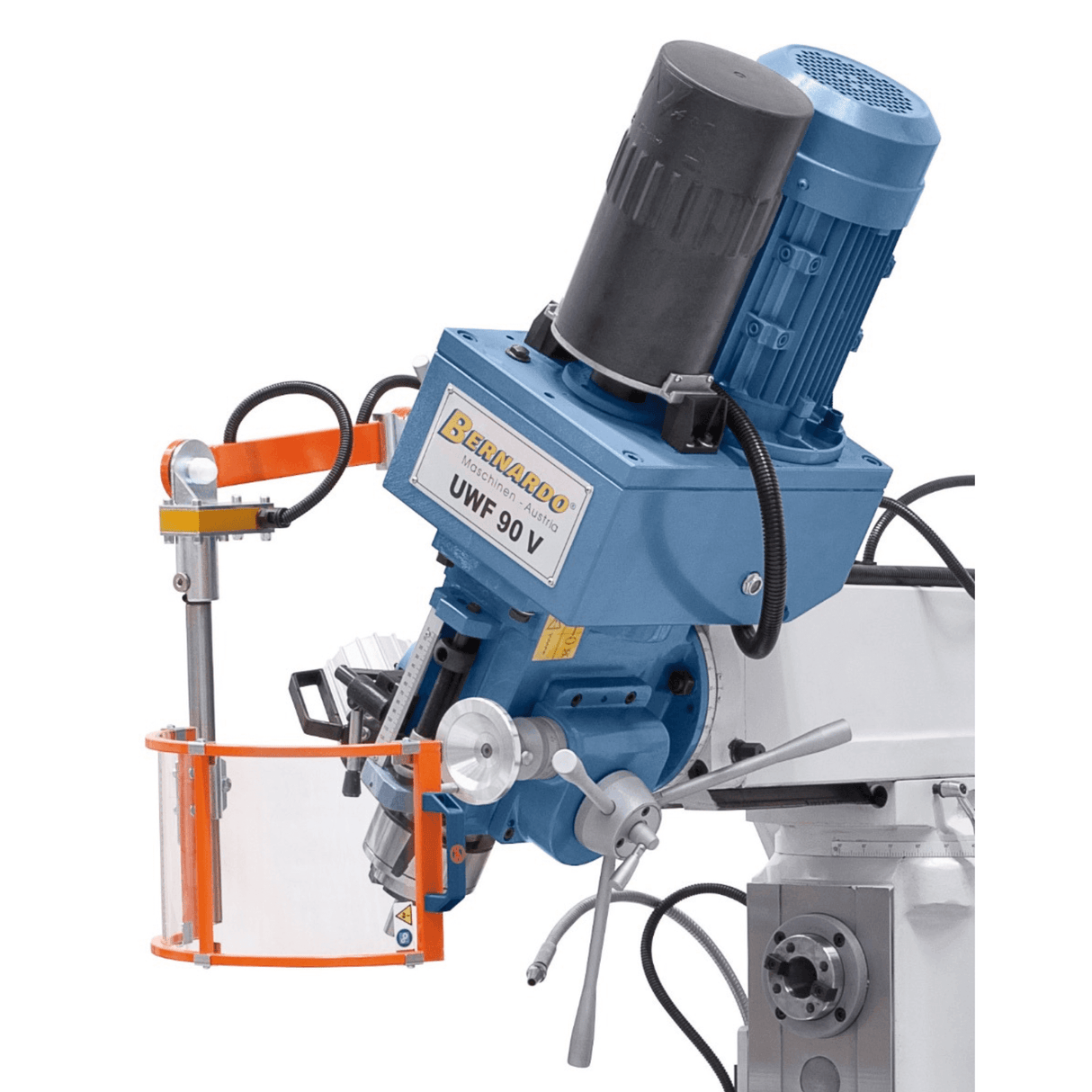

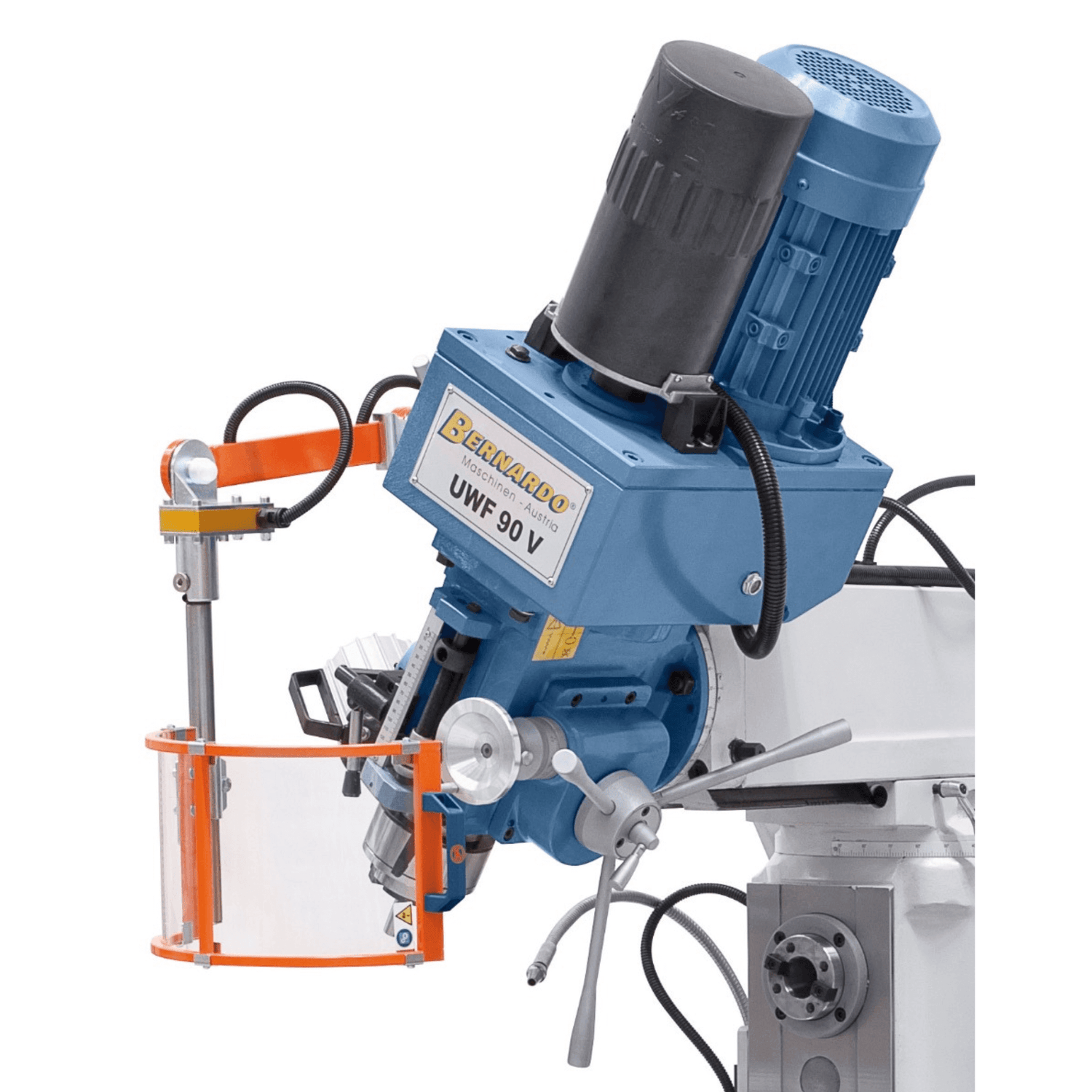

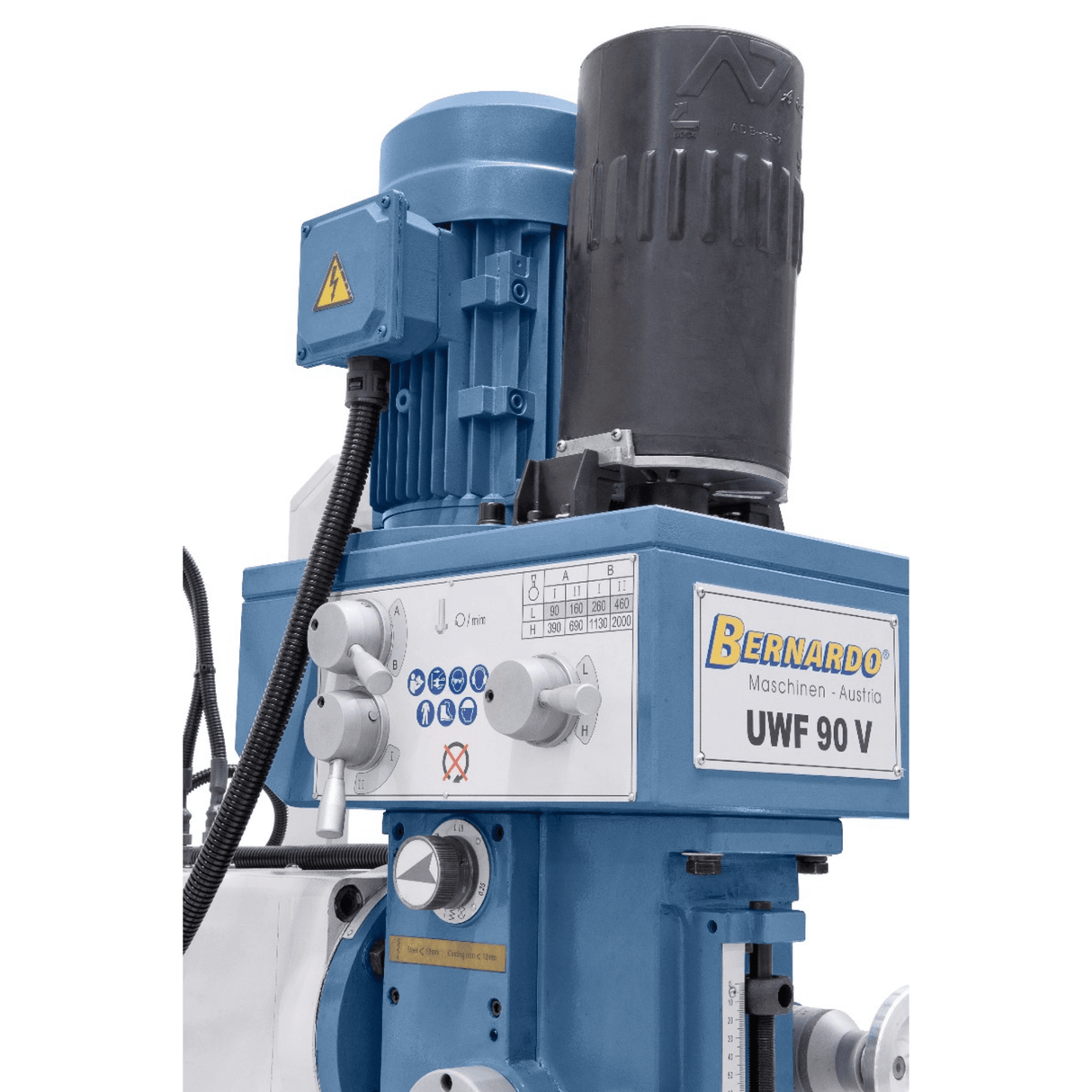

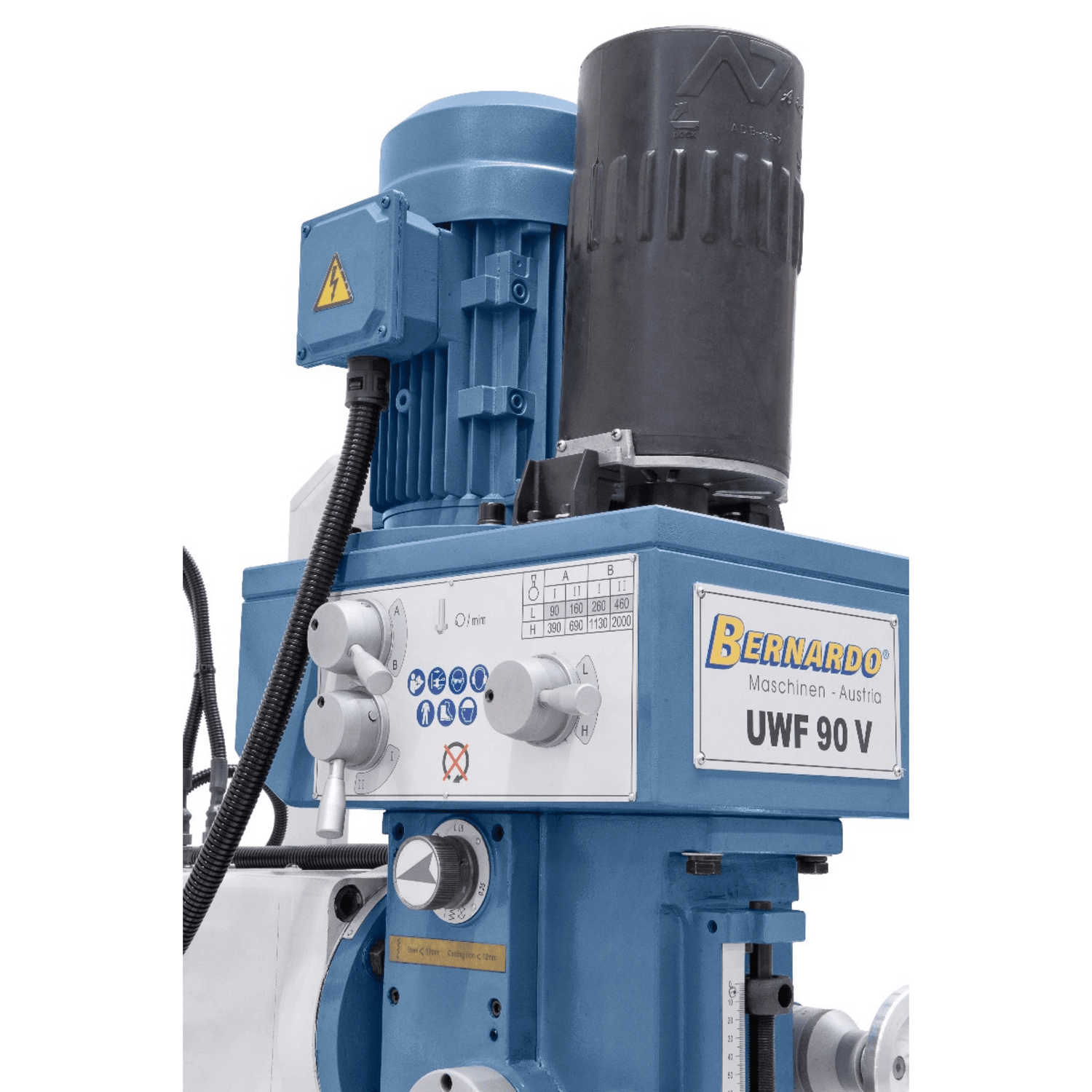

Universal Milling Machine UWF 90 V Vario

The UWF 90 V Vario Universal Milling Machine is designed to ensure high precision and productivity when machining single pieces or small batches. Thanks to its ease of use and versatility, it is particularly suitable for mechanical engineering, plant manufacturing, and the manufacture of individual components. The UWF 90 V Vario model is equipped with automatic feeds on the X and Y axes, a motor for positioning the Z axis, and an automatic spindle feed system. These features ensure a continuous and precise workflow, optimizing production and reducing downtime. The machine is also built with a solid cast iron base, ensuring vibration-free operation.

Main Features:

- Pneumatic Clamping : Cutter changes are made quickly by pneumatically clamping the workpieces, improving operating efficiency.

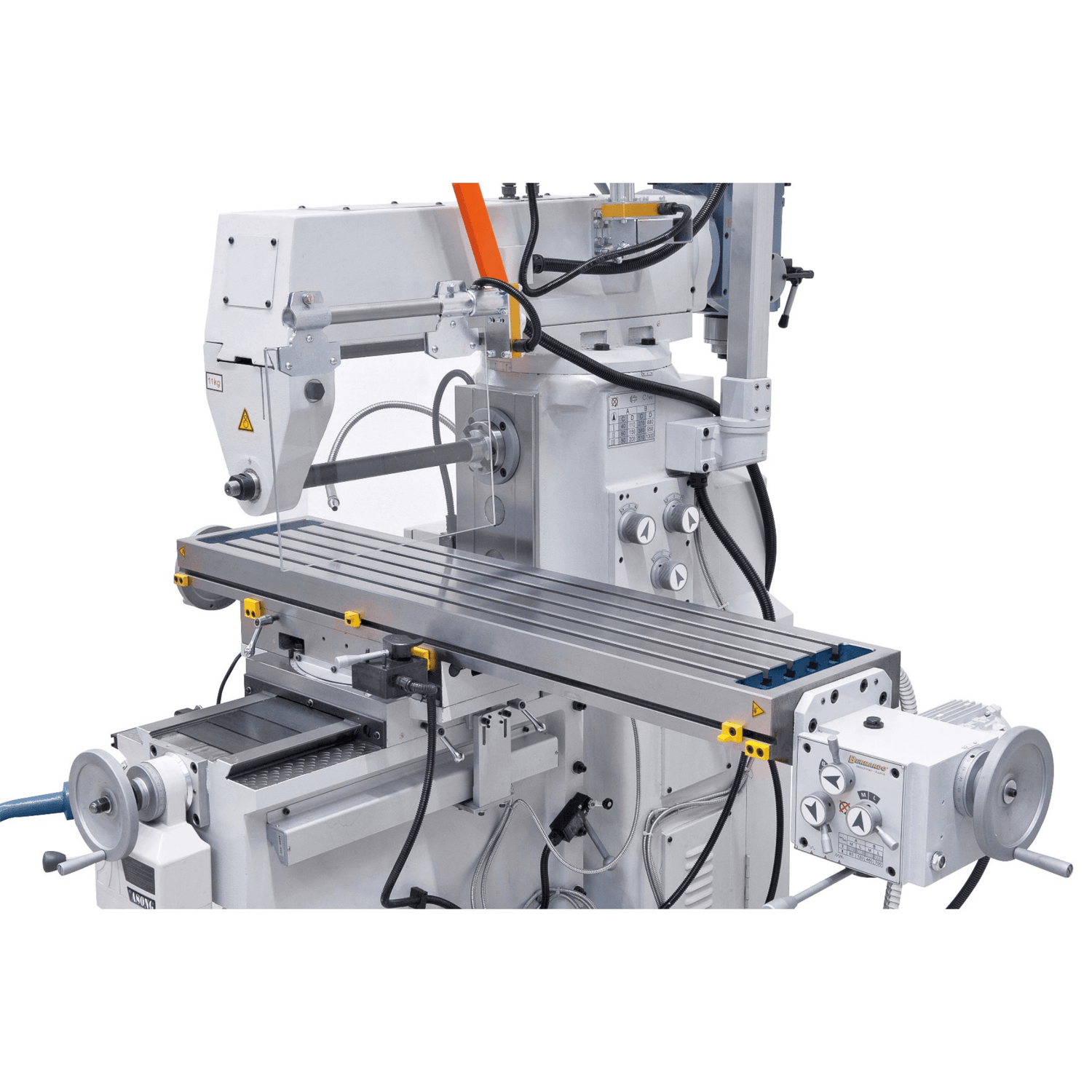

- Automatic Feed and Rapid Traverse : Automatic feeds on the X and Y axes, together with rapid traverse, allow for precise and fast machining, reducing waiting times.

- Z-Axis Positioning Motor : The Z-axis motor provides accurate control, making positioning operations easier during machining.

- Automatic Spindle Feed : With a feed rate of 0.08 – 0.25 mm/rev, the automatic spindle feed system ensures precision in drilling and milling operations.

- Robust Construction : The cast iron base and heavy valve guides ensure stability and minimize vibrations, improving the quality of the machining.

- Silent Gears : The transmission gears, operating in an oil bath, ensure smooth and silent operation, increasing the durability of the machine.

Standard Accessories:

- ES-12 H 3-Axis Position Display with LCD Display

- Pneumatic workpiece clamping (DIN 2080)

- M 16 clamping chuck

- Horizontal external support

- Adjustable protection device

- Protective cover for horizontal milling

- ISO 40 / B18, ISO 40/MK 3 adapter

- Reduction socket MK 3/2

- Long drill chuck ISO 40/27 mm, ISO 40/32 mm

- Refrigeration system

- LED car light

- Advanced control device

Technical Specifications :

| Characteristic | Detail |

|---|---|

| Table dimensions | 1270 x 280 mm |

| Spindle attachment | ISO 40 |

| Number of revolutions of the vertical spindle | (8) 90 – 2000 rpm |

| Horizontal spindle speed | (12) 40 – 1300 rpm |

| Hole stroke | 120 mm |

| Spindle power supply | 0.08 / 0.15 / 0.25 mm/rev |

| Longitudinal travel (X) | 750 mm* |

| Transverse stroke (Y) | 230 mm |

| Vertical stroke (Z) | 300 mm |

| Length of the arms | 240 – 740 mm |

| Tilting table | from -45° to +45° |

| Spindle head tilt area | from -90° to +90° |

| Spindle/table distance | 125 – 425 mm |

| Longitudinal advancement area | (8) 32 – 700 mm/min |

| Z-axis rapid traverse | 660 mm/min |

| T-slot size | 14 mm |

| Vertical motor power | 2.2 kW |

| Horizontal engine power | 2.2 kW |

| Machine dimensions (L x W x H) | 1750 x 1500 x 2200 mm |

| Weight | 1310 kg |

- Manual longitudinal stroke

The UWF 90 V Vario Universal Milling Machine is an ideal solution for workshops requiring a versatile and precise machine for producing single parts or small batches. Equipped with automatic feeds and a spindle feed system, the UWF 90 V Vario is designed for ease of use and high productivity, while maintaining superior workmanship thanks to its robust and stable construction.