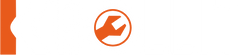

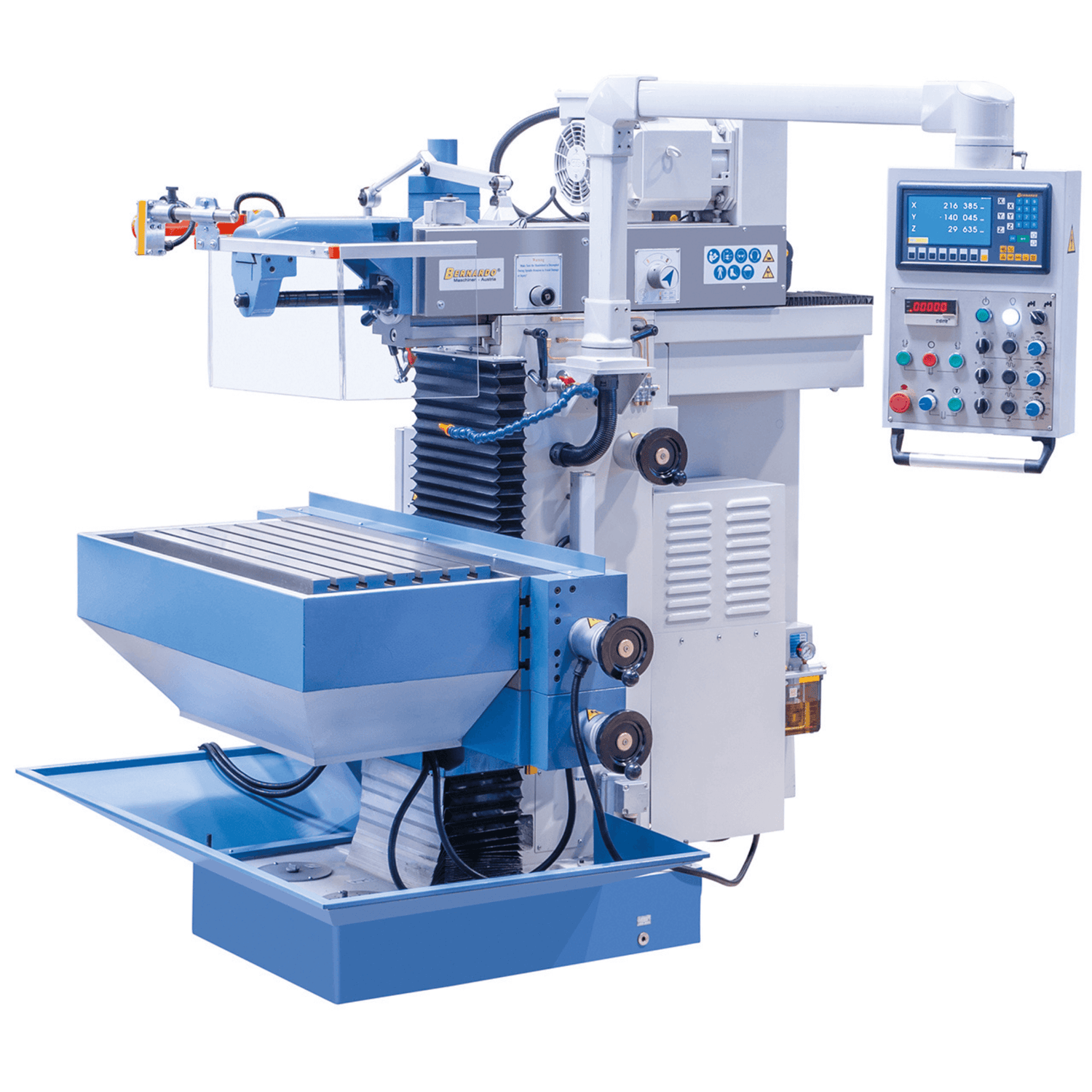

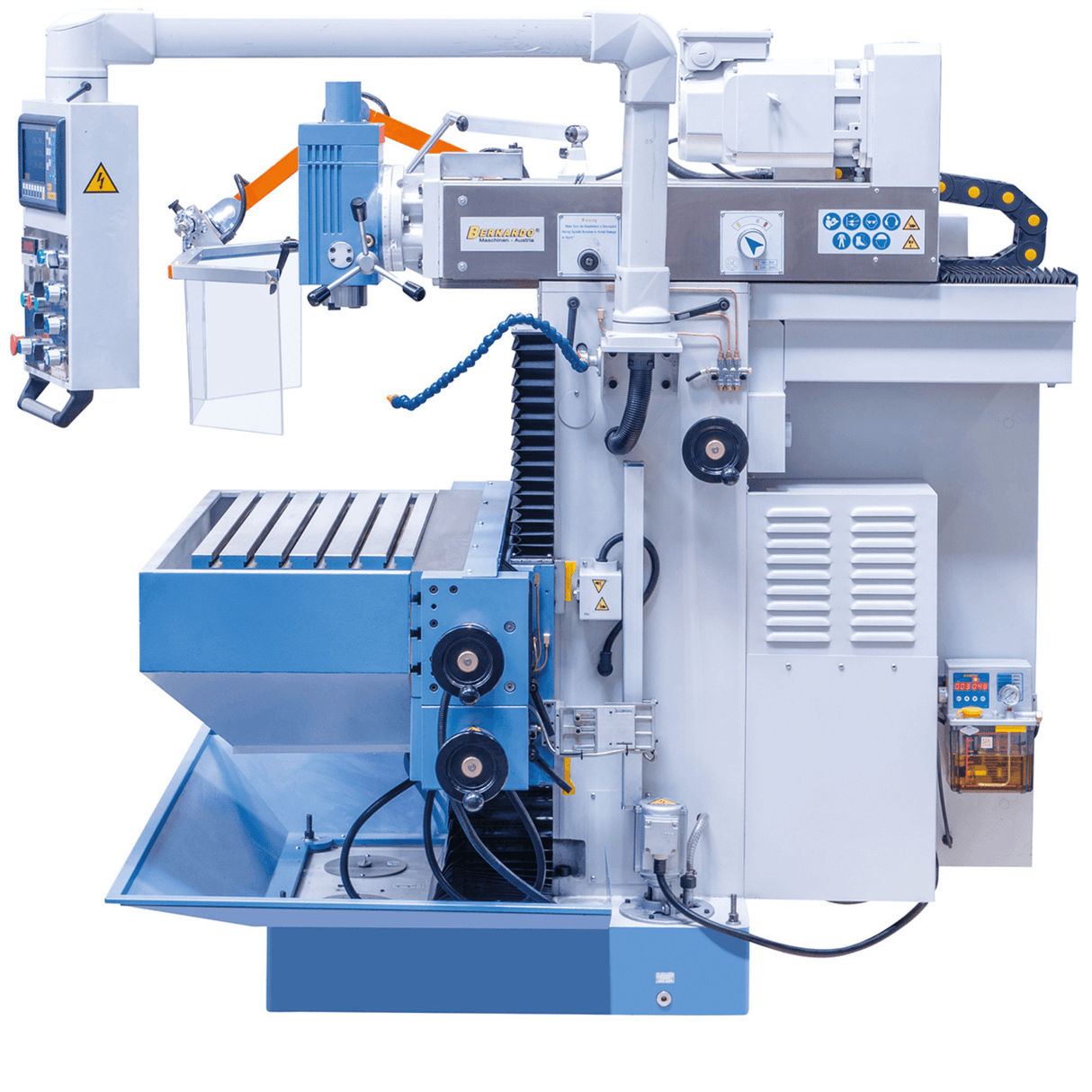

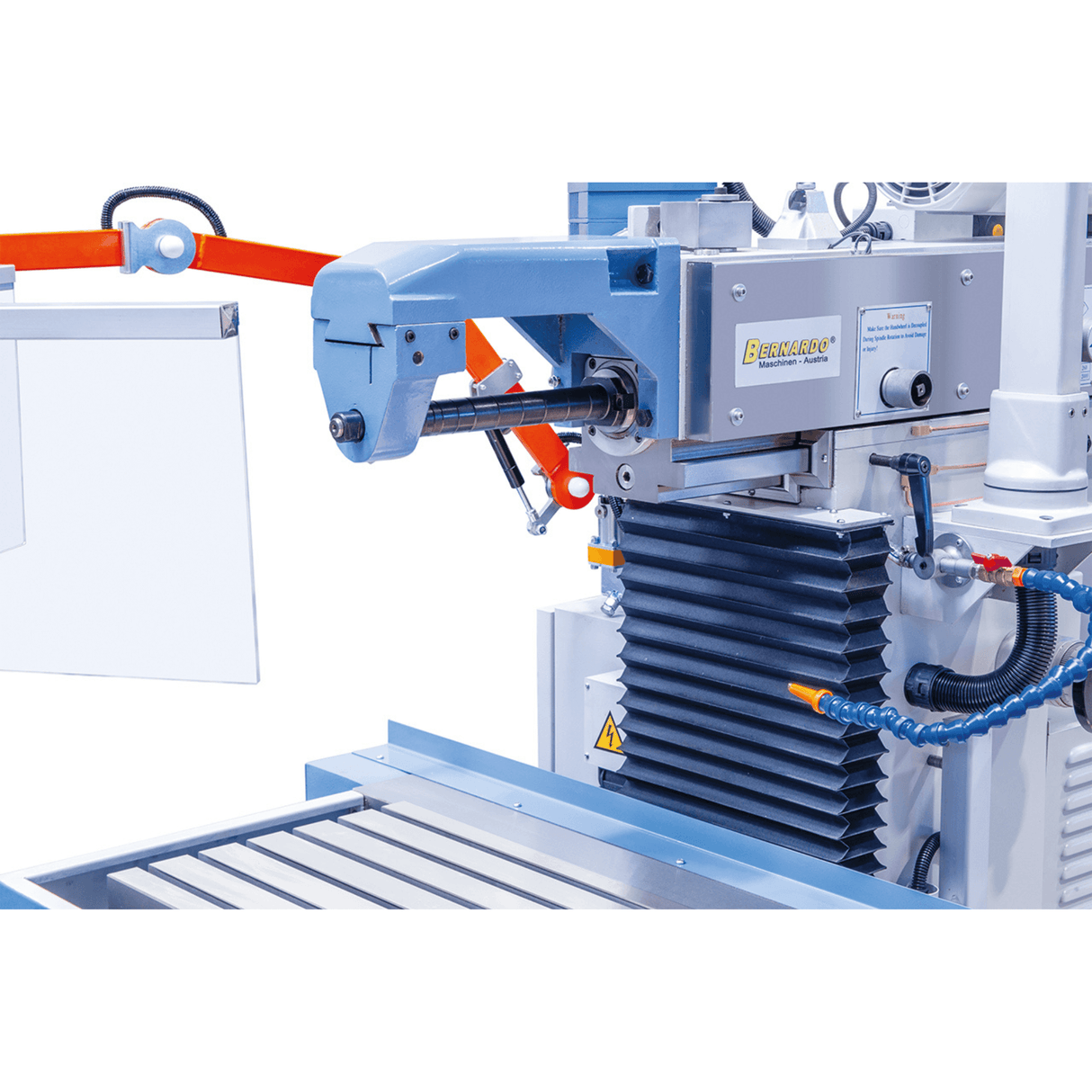

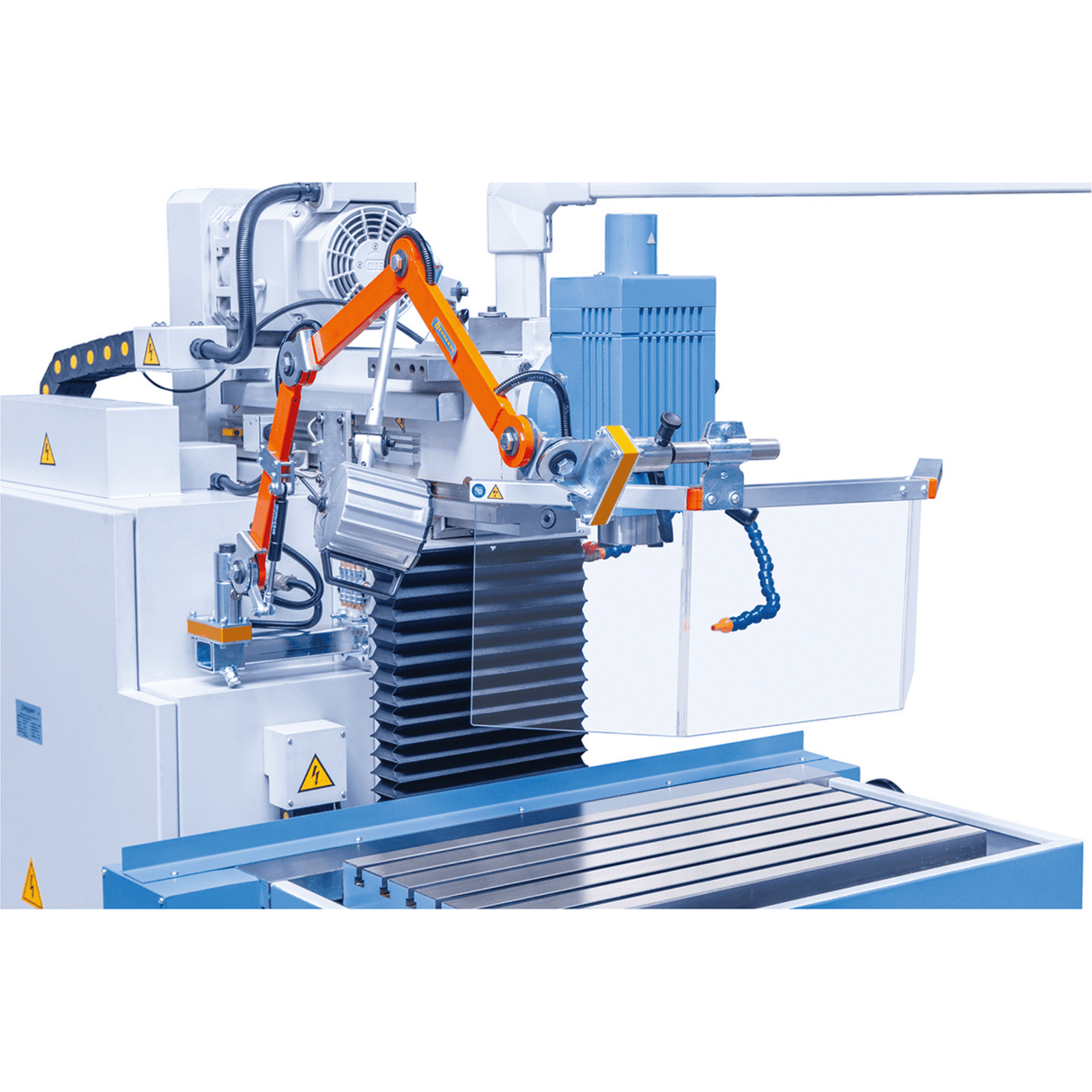

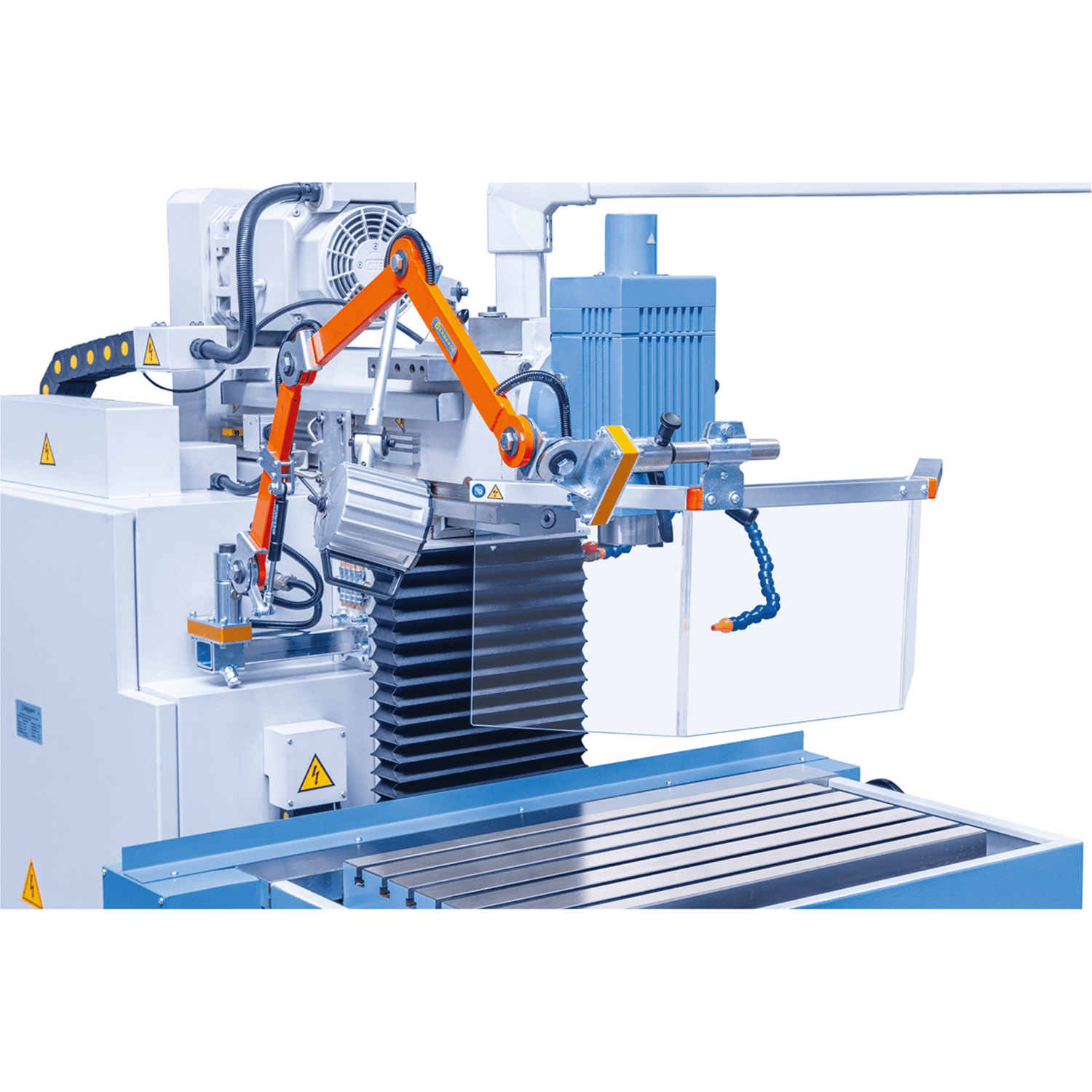

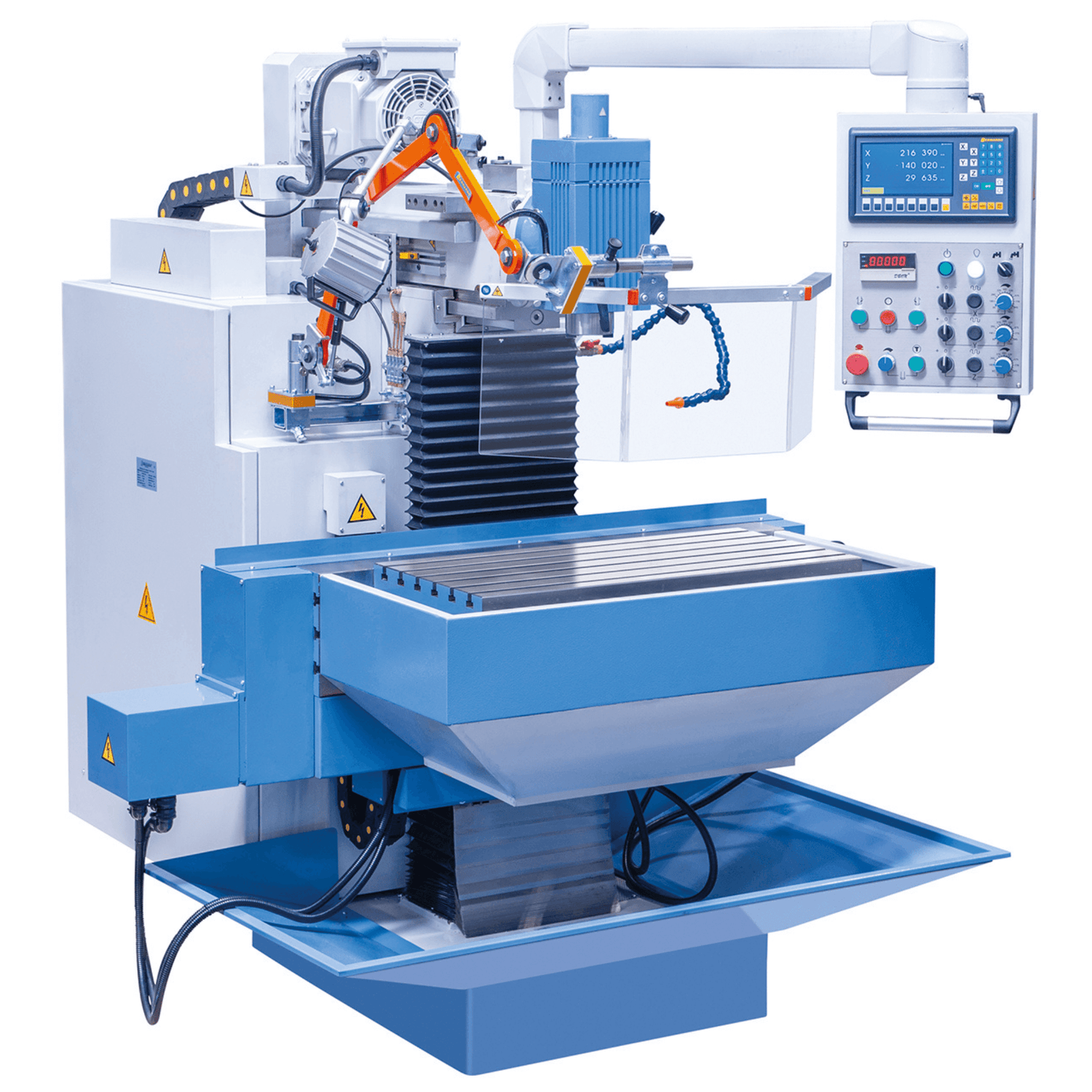

WFM 800 Servo Tool Milling Machine

WFM 800 Servo Tool Milling Machine is backordered and will ship as soon as it is back in stock.

Subscribe to our newsletter

Get the latest updates on all our new collections, sales, offers and product arrival dates.

-

Description

-

Technical Specifications

-

Product safety

-

Reviews

Description

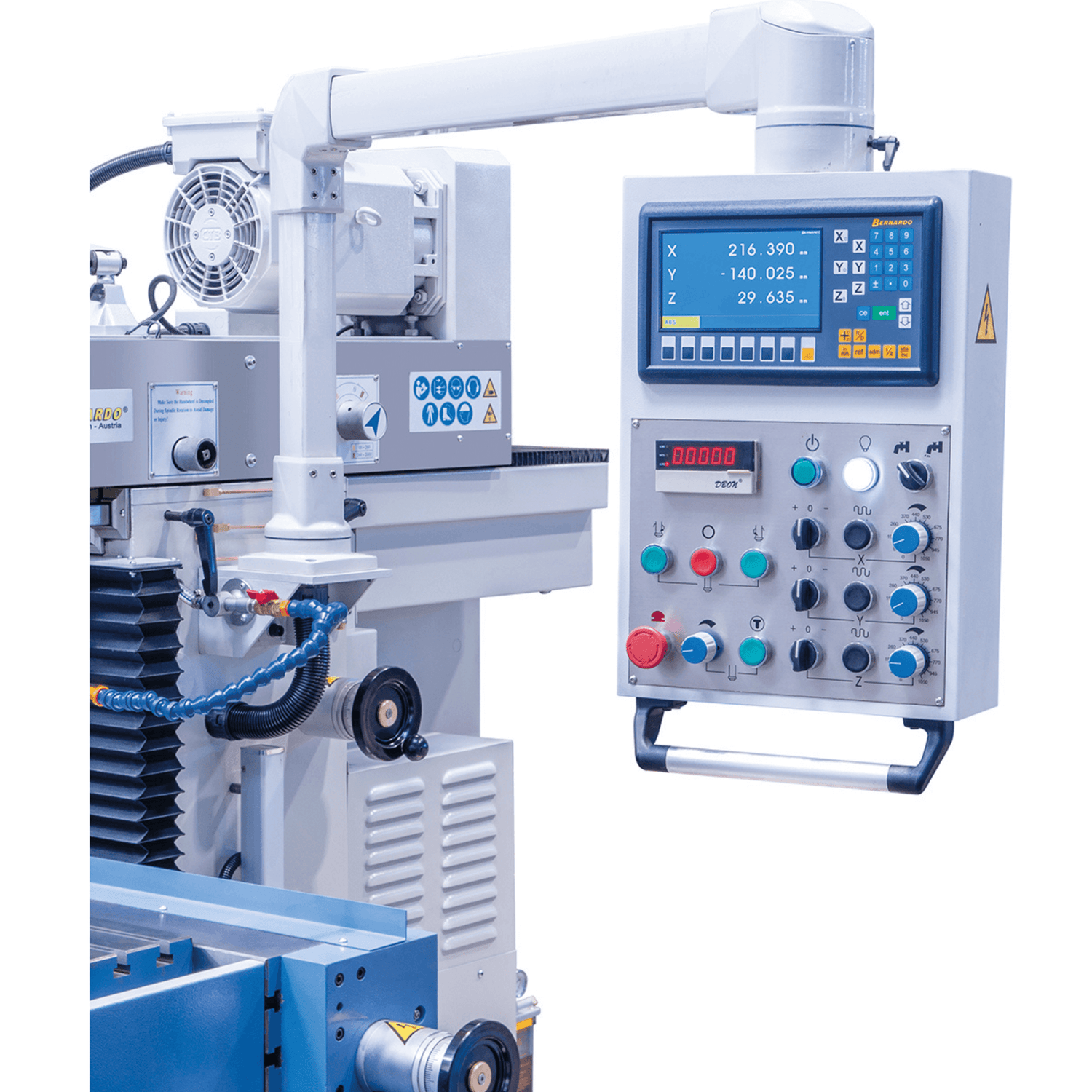

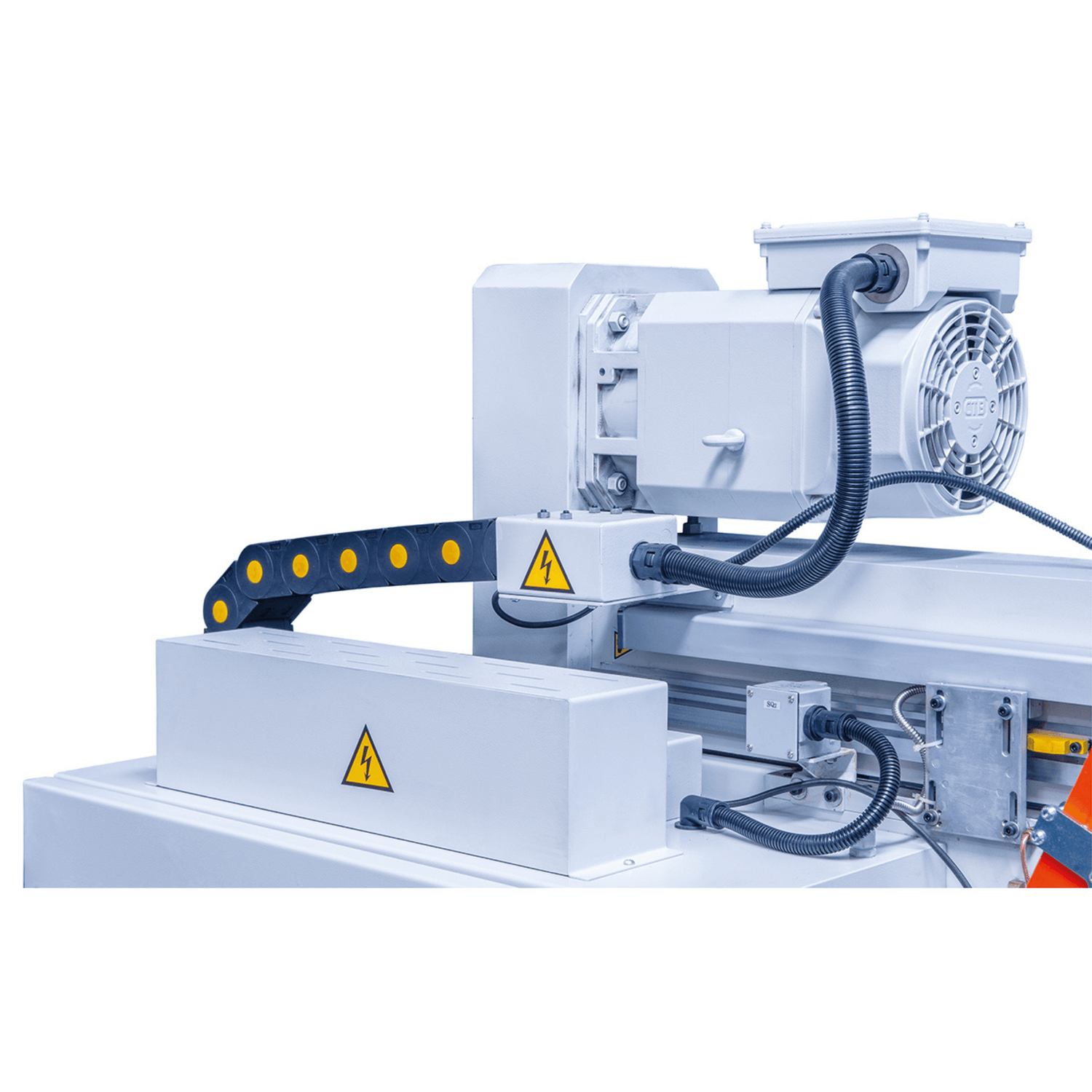

The WFM 800 Servo milling machine is designed for machining workpieces weighing up to 200 kg. Thanks to its stable and robust cast iron construction and the high rigidity of its machine components, this model meets the best requirements for precise machining. The main features of this machine are: a servo-controlled turret with electronic handwheels on all axes and a continuously variable speed controller.

Property

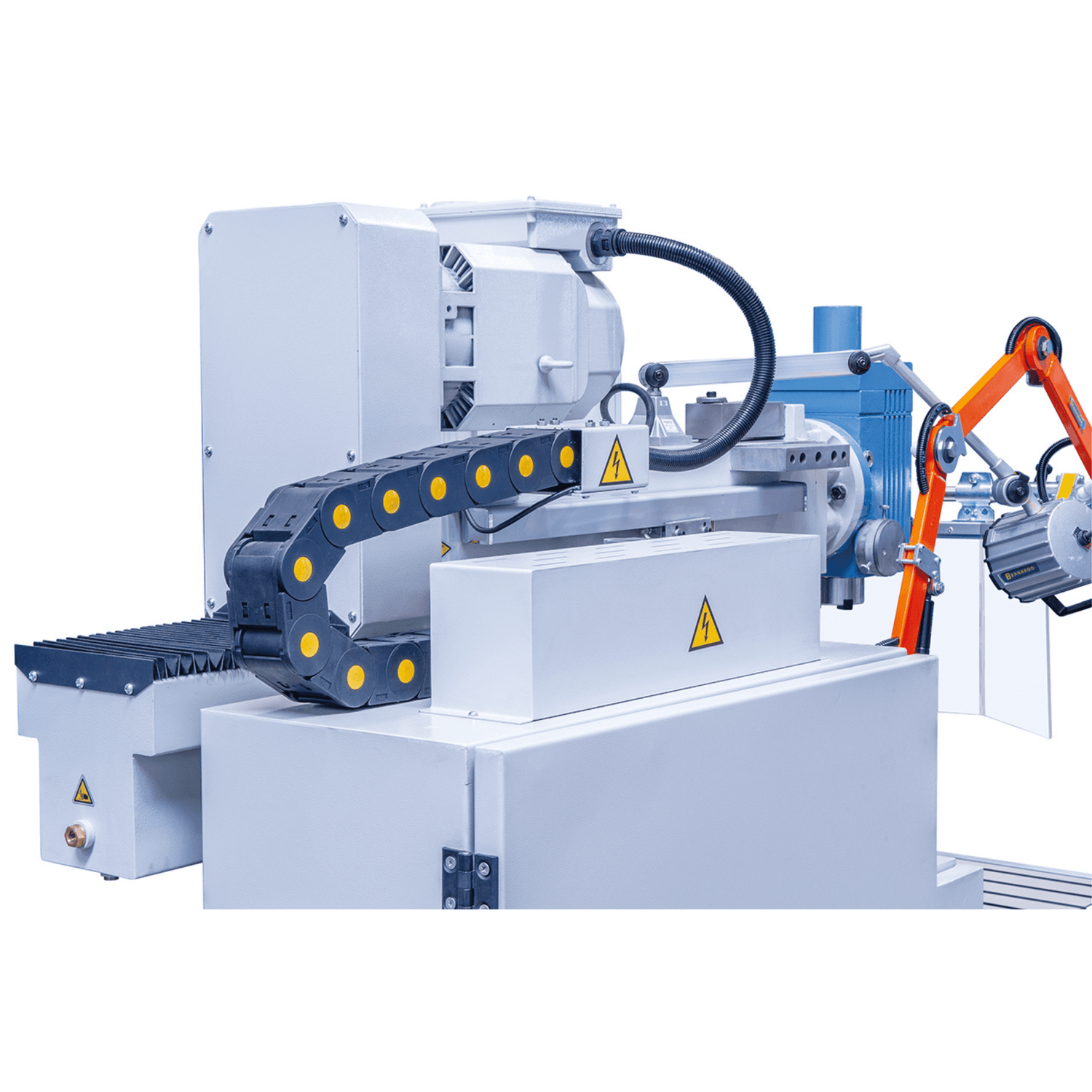

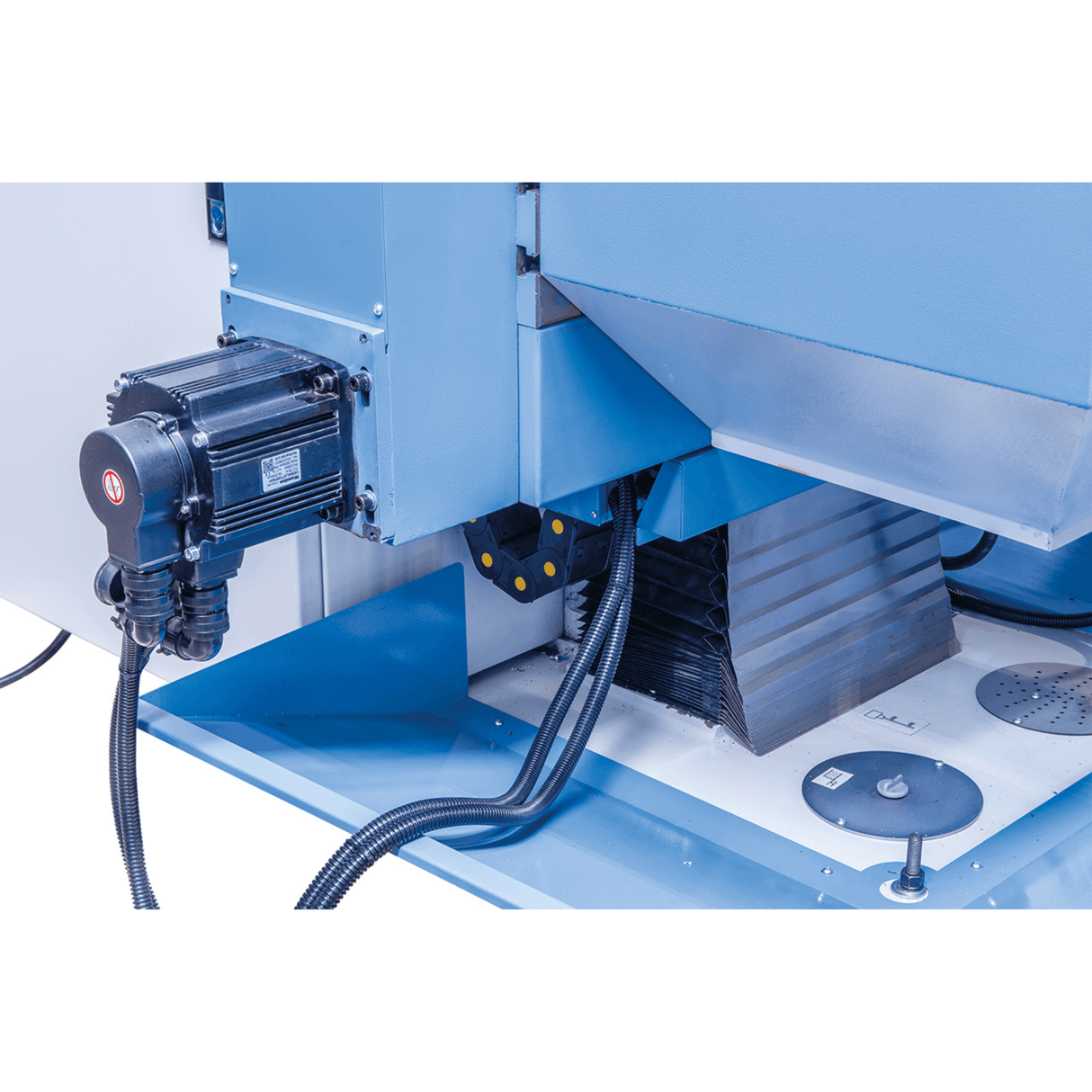

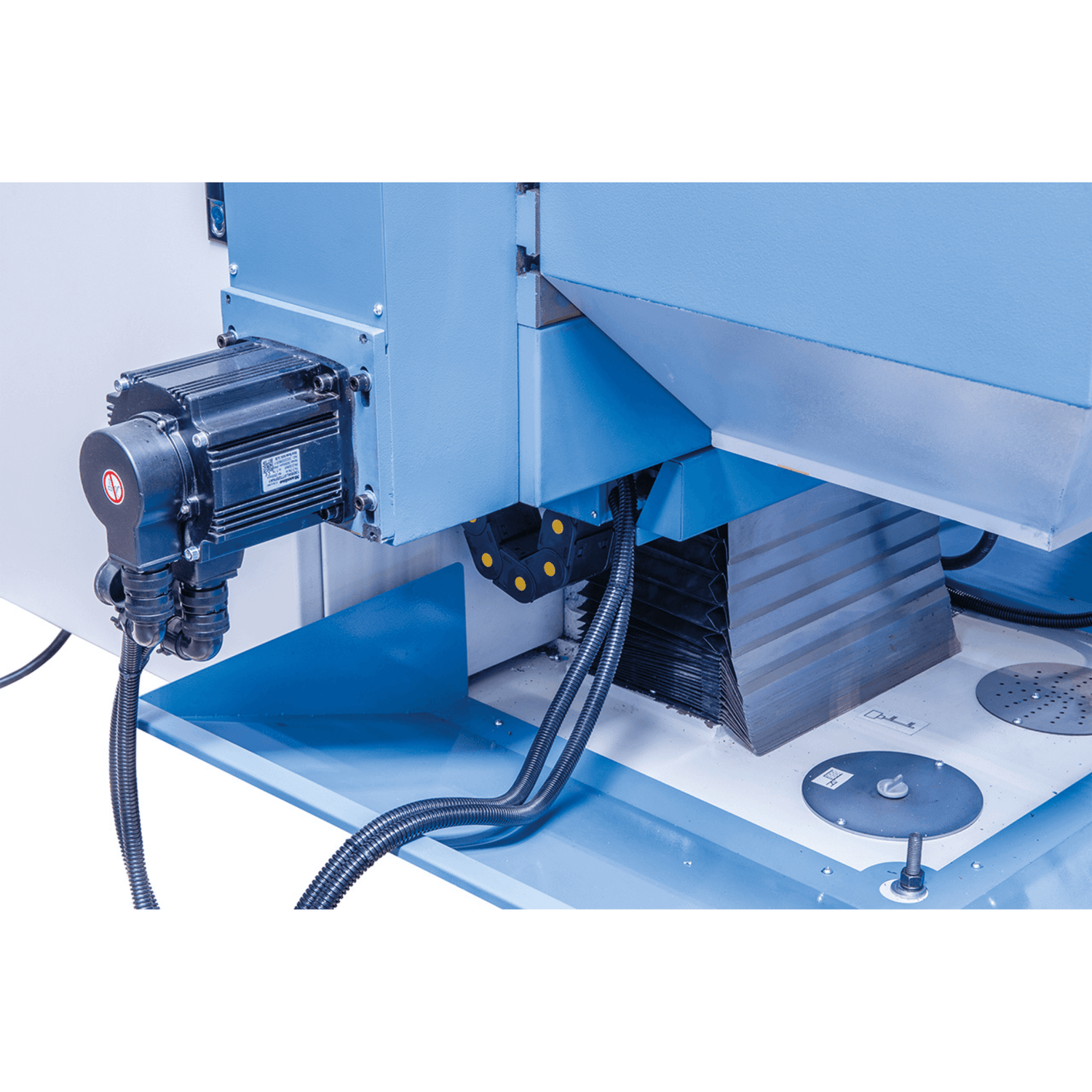

- Continuous automatic feed and rapid travel in all axes, driven by the servo motor

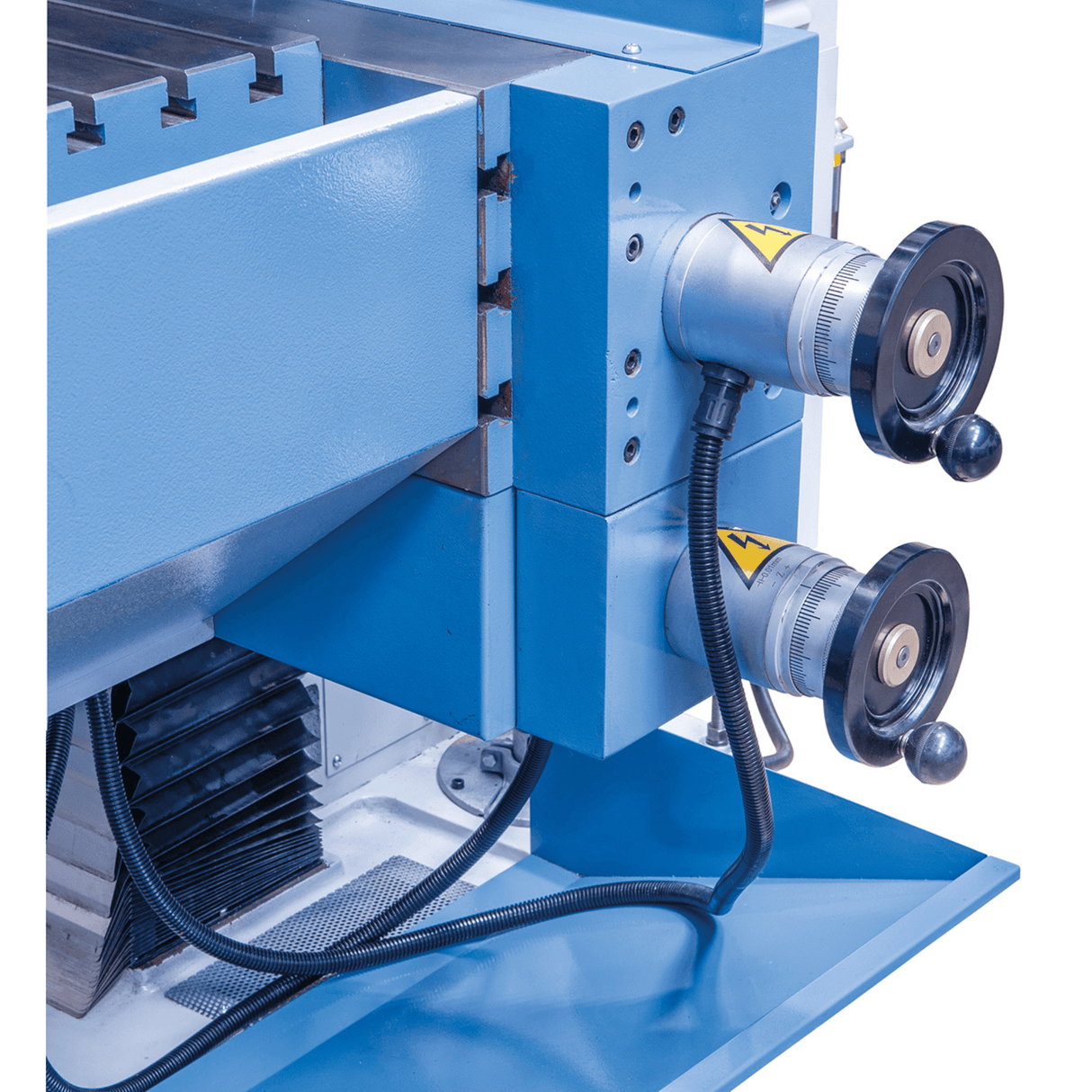

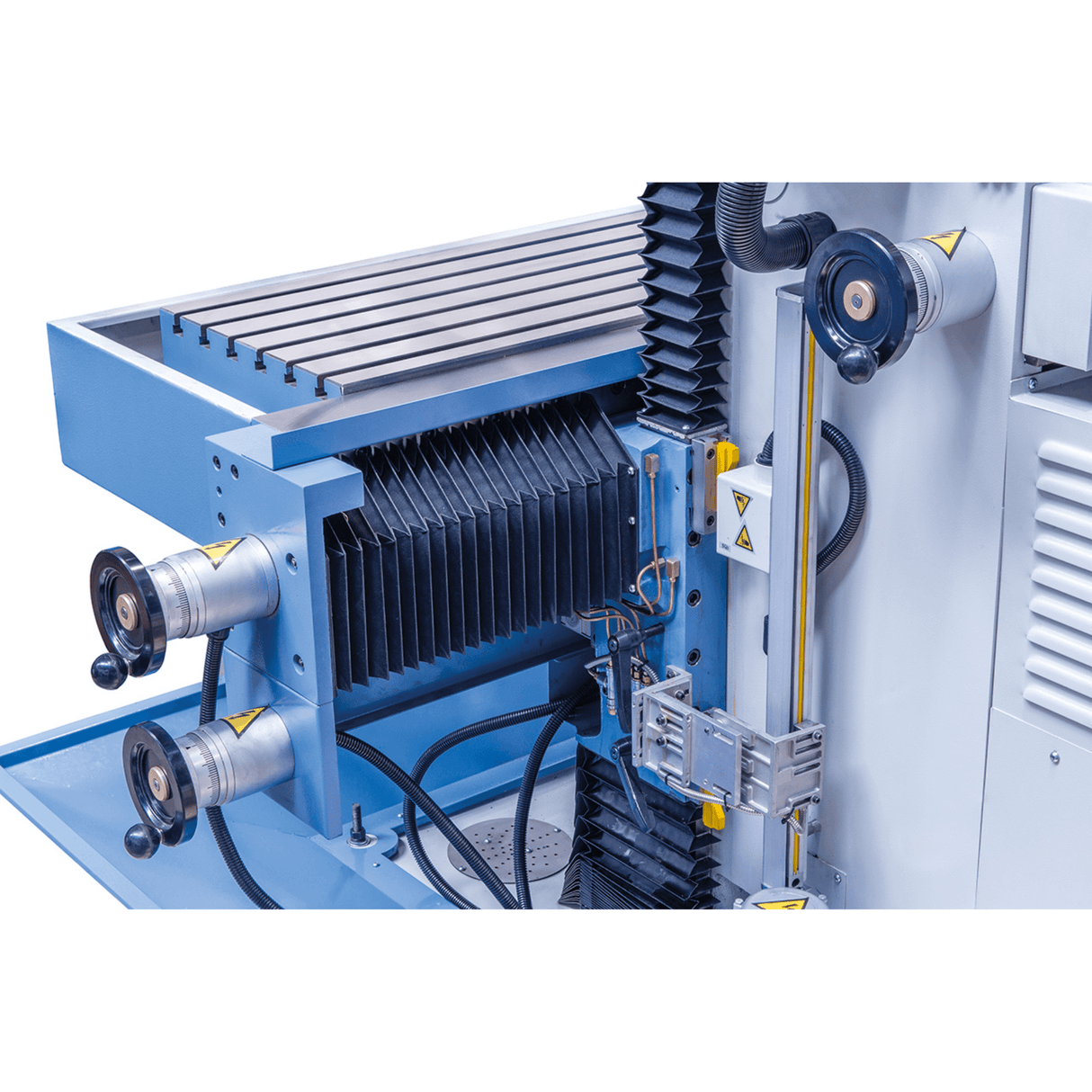

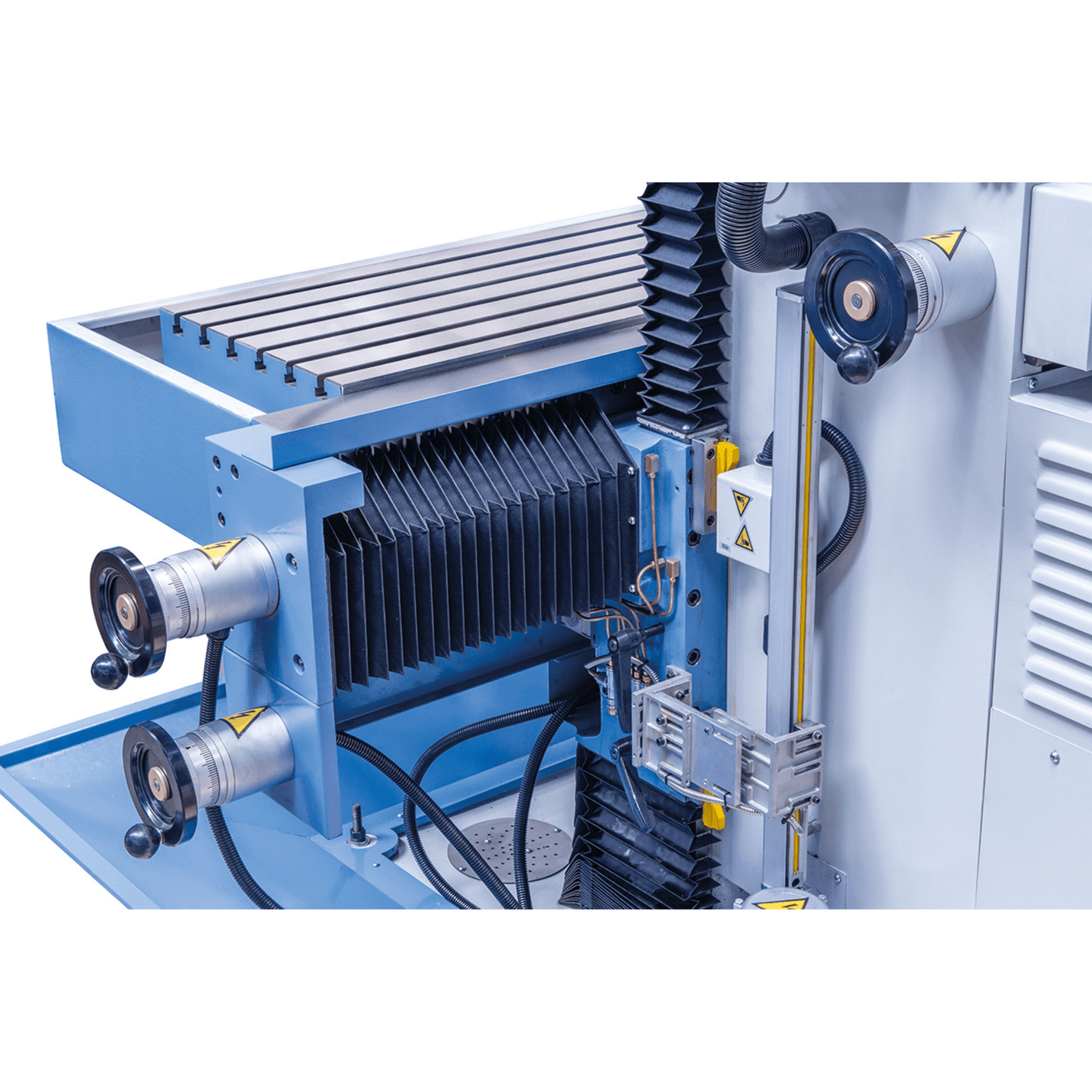

- Backlash-free preloaded rotary ball spindles in all 3 axes

- Economical processing of various materials through optimal adjustment of the freely selectable spindle speed and feed rates

- Variable speed setting via Siemens frequency converter with optimum torque curve and approximate constant speed under load

- Equipped as standard with 3 electronic handwheels for manual movement in all axes

- Machine base with heavy cast iron valve guides for vibration-free operation

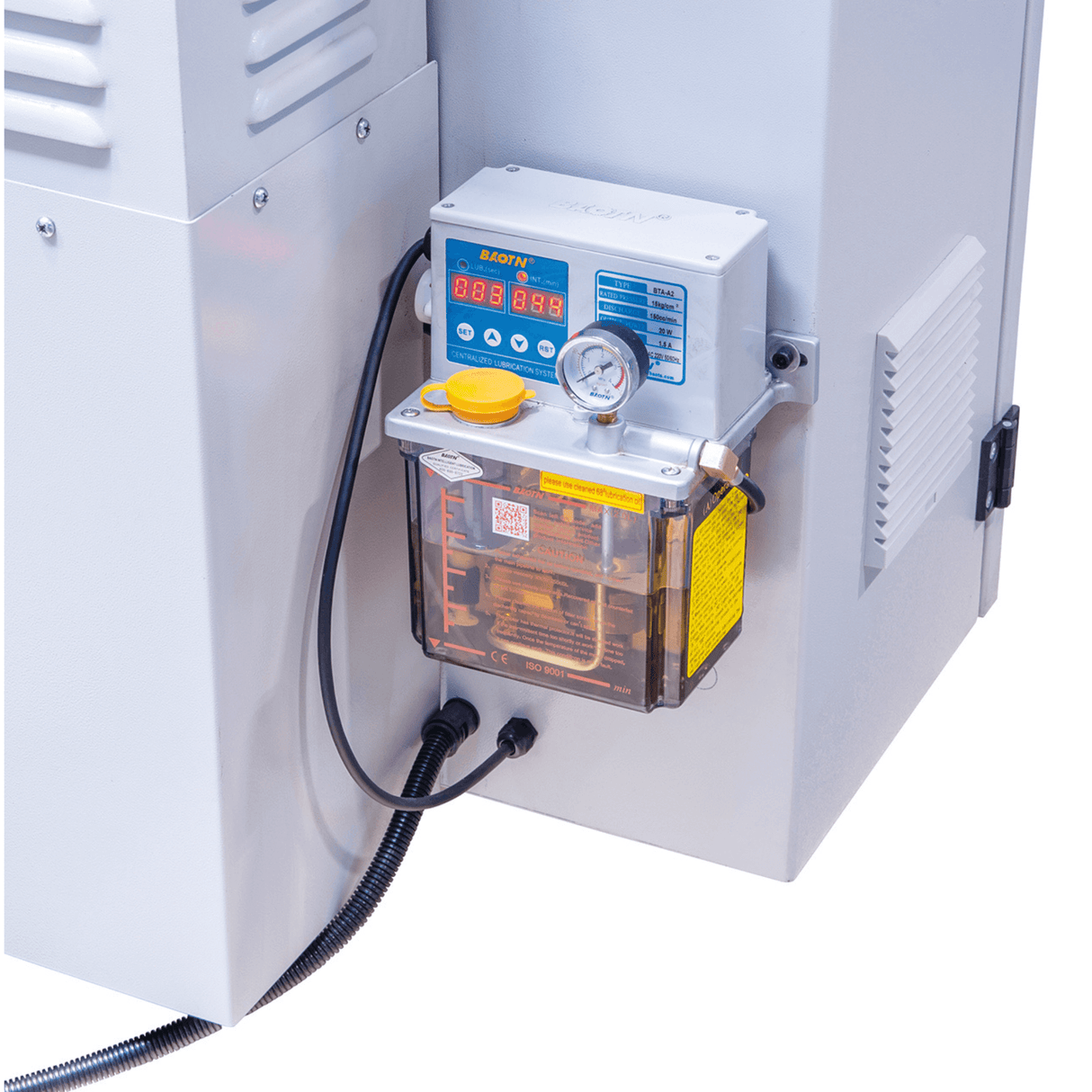

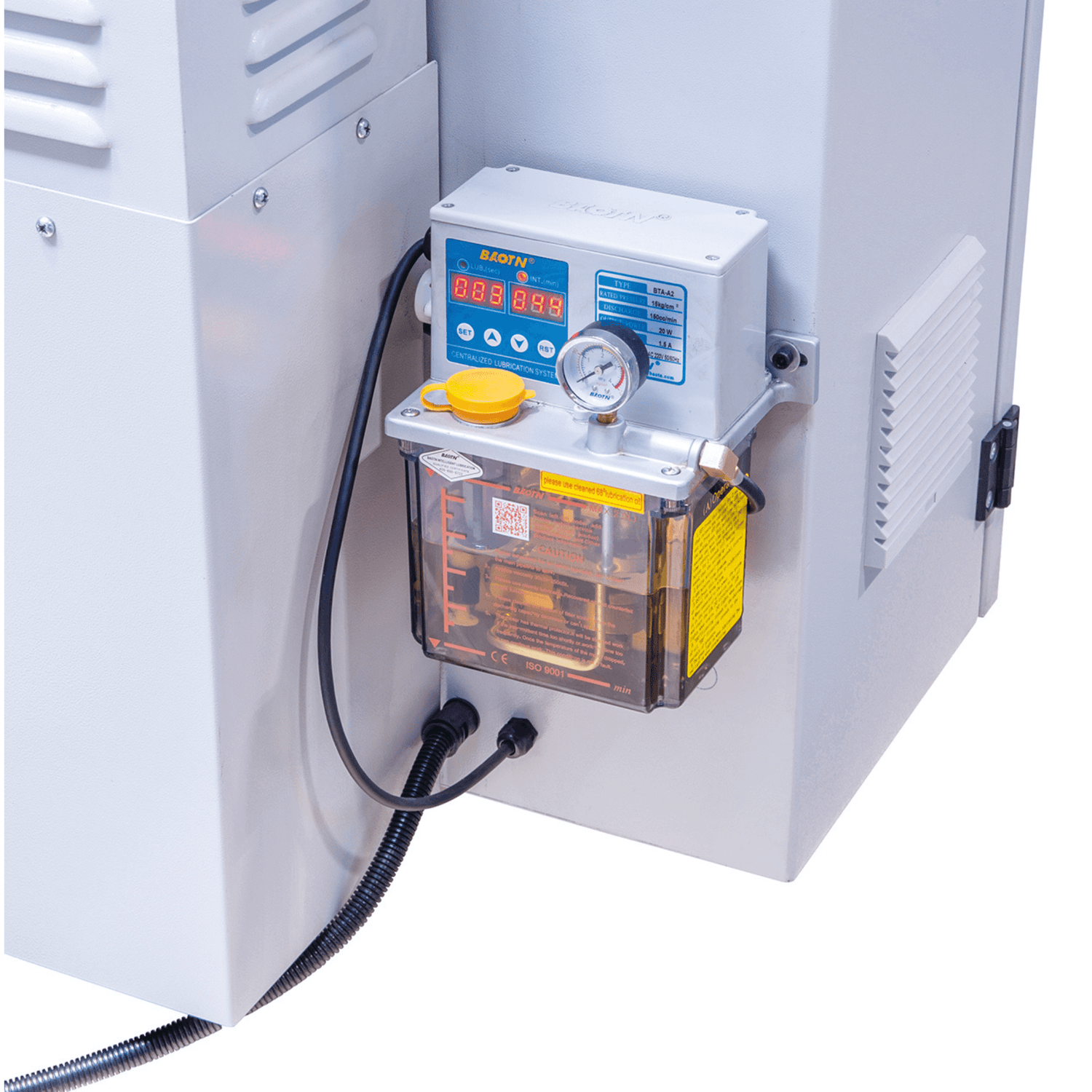

- Equipped with central lubrication for the guides

- For horizontal milling the vertical milling head is moved away

- Maximum silence thanks to the transmission gears operating in an oil bath

Standard accessories

- ES-12 H 3-Axis Position Display with LCD Display

- LED car light

- Refrigeration system

- Electronic flyers

- Horizontal external support

- 3-axis ball screws

- M 16 clamping chuck

- Power plant lubrication

- Slat protection cover

- Long drill chuck ISO 40/16 mm, ISO 40/22 mm, ISO 40/27 mm, ISO 40/32 mm

- Adapter ISO 40 / MK 3, ISO 40 / MK 2, ISO 40 / MK 1

- Machine skates

- Universal protection device

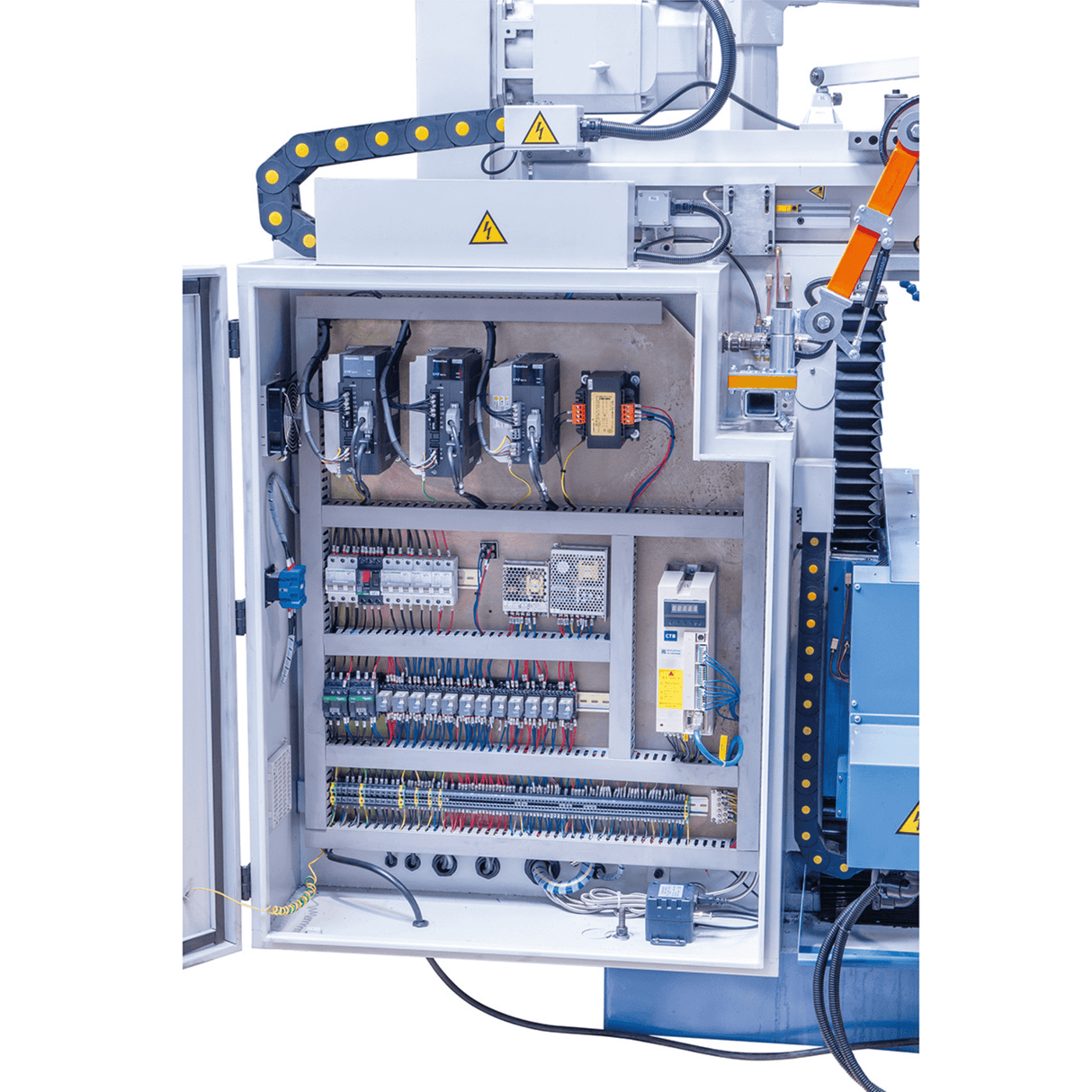

- Control device

technical specifications

Table dimensions |

800 x 400 mm |

Vertical clamping surface |

1020 x 225 mm |

Longitudinal travel (x) |

405 mm |

Transverse travel (y) |

400 mm |

Vertical travel (z) |

400 mm |

Table load |

200 kg |

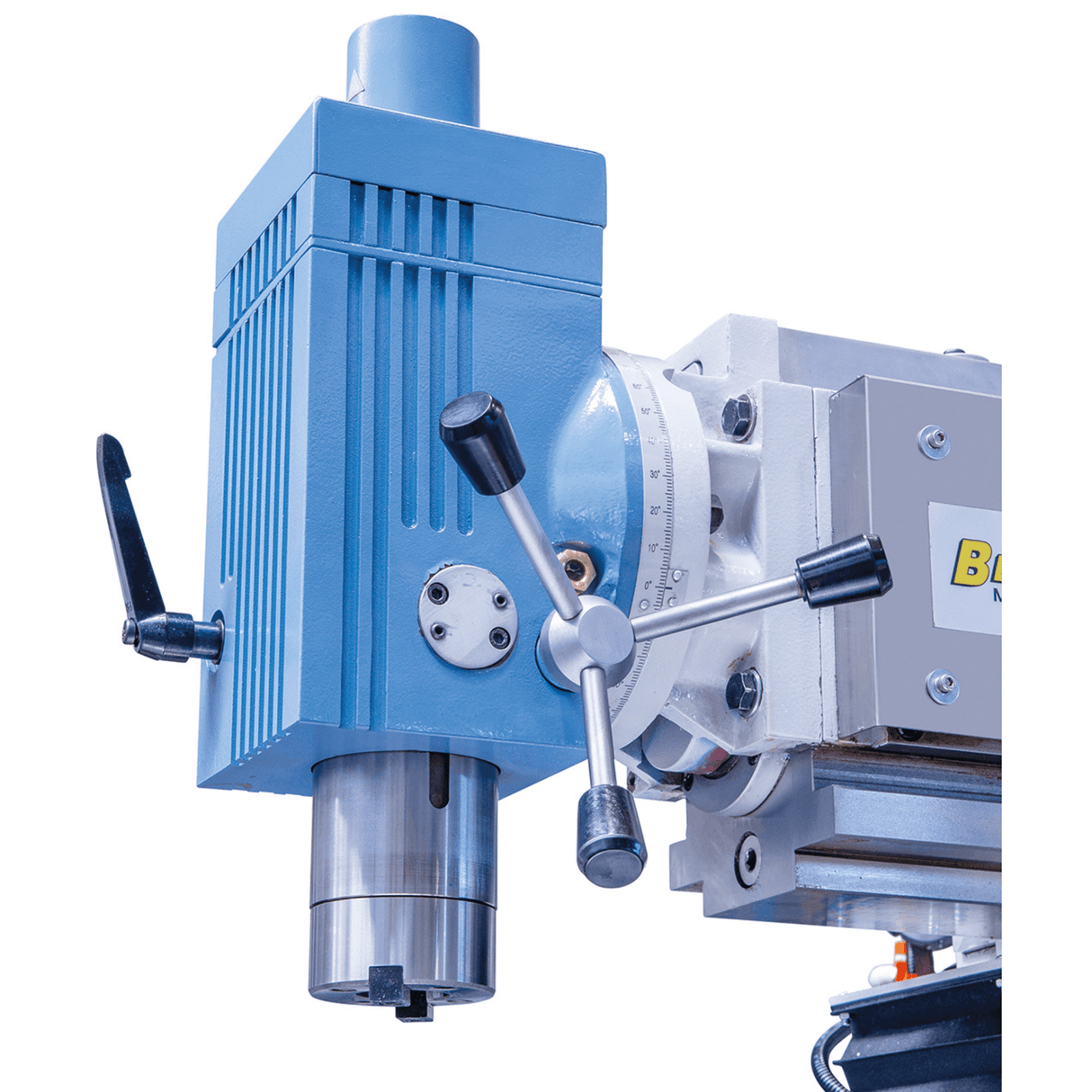

Vertical milling head |

|

Continuous spindle speed |

40 – 260 / 260 – 2000 rpm |

Spindle attachment |

ISO 40 |

Hole stroke |

60 mm |

Max. arm length |

170 - 570 mm |

Spindle/table distance |

45 – 445 mm |

Spindle head tilt area |

from -90° to +90° |

Horizontal milling head |

|

Continuous spindle speed |

40 – 260 / 260 – 2000 rpm |

Spindle attachment |

ISO 40 |

Feed rate |

|

x-axis / y-axis / z-axis |

10 – 1000 mm/min |

Rapid travel (x / y / z) |

1200 mm/min |

T-slots (number, width, spacing) |

6 / 14 mm / 63 mm |

T-slots vertical table (num. / width / dist.) |

3 / 14 mm / 63 mm |

Feed motor (x/y/z) |

1.925 / 1.925 / 1.5 KW |

Main engine |

3.75 kW |

Machine dimensions (L x W x H) |

1500 x 1700 x 1800 mm |

Weight approx. |

1500 kg |