-

Description

-

Technical Specifications

-

Product safety

-

Reviews

Description

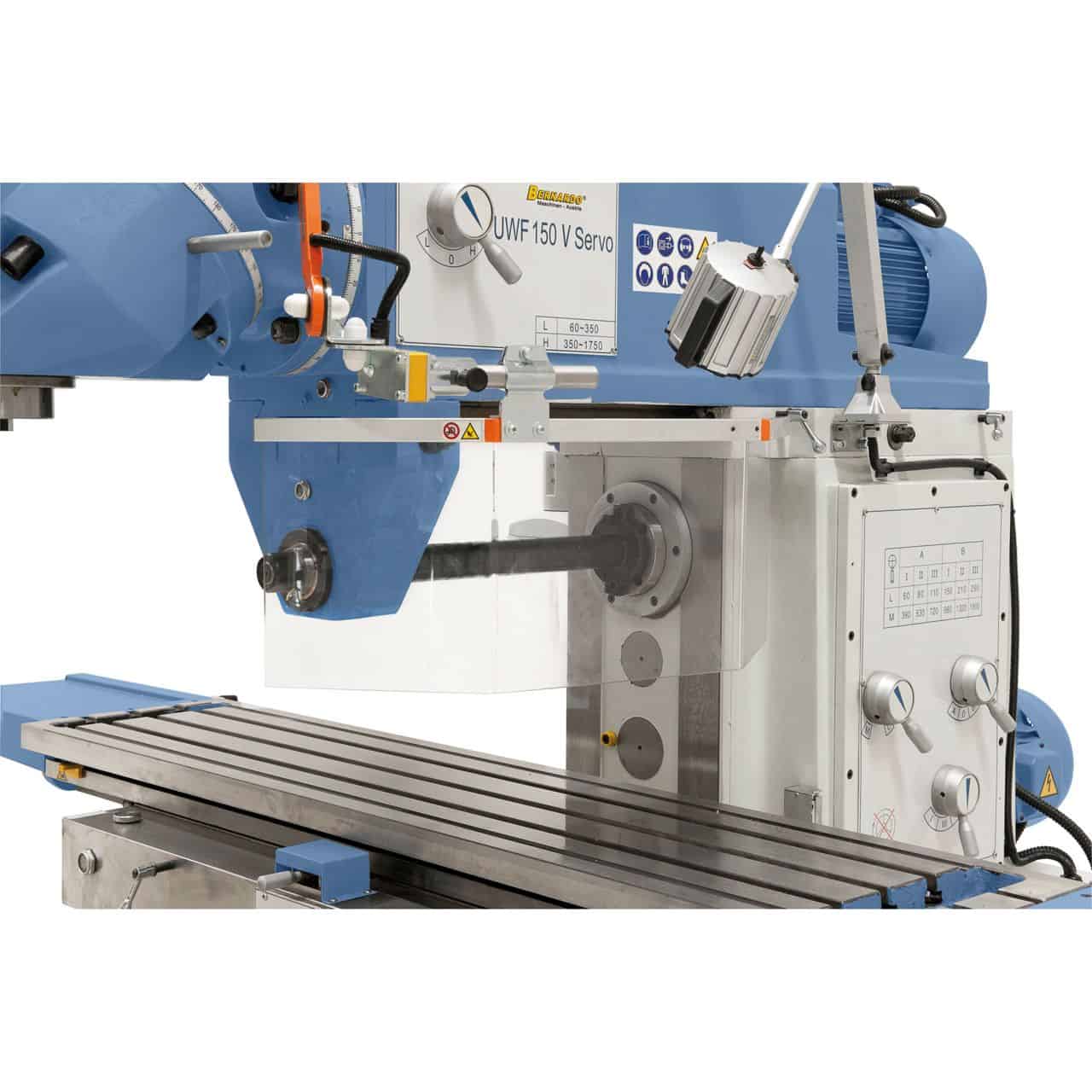

UWF 150 V Servo Universal Milling Machine

The UWF 150 V Servo Universal Milling Machine is a versatile machine designed for precision industrial machining. Its robust construction, with a movable arm and a large table clamping surface, makes it ideal for operations on large workpieces. The hardened and ground precision guideways ensure maximum stability and accuracy, even under heavy loads. The variable-speed vertical spindle, controlled by a Siemens frequency converter, allows for optimal torque and constant torque under load, ensuring efficiency and reliability.

Main Features:

- Variable Speed Regulation : The speed of the vertical spindle can be continuously varied thanks to the Siemens frequency converter, ensuring optimal torque distribution and constant torque.

- Hardened and Ground Precision Guides : The large guides on all axes offer high working precision, improving stability even with heavy loads.

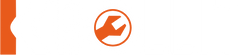

- Servo-assisted feed : Finely graduated feeds in all axes are driven by a servo motor for precise movement control, plus rapid traverse on the X, Y and Z axes to reduce downtime.

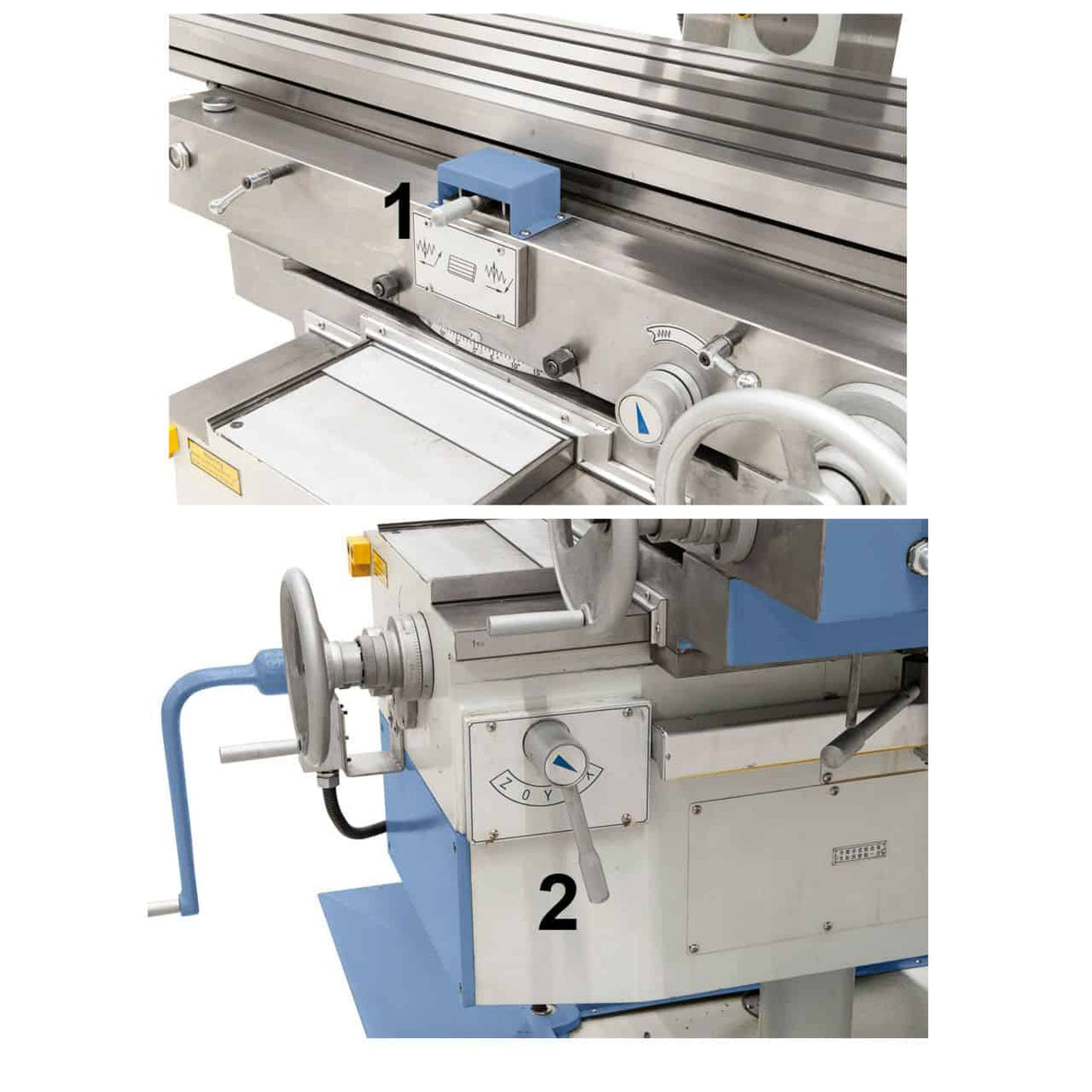

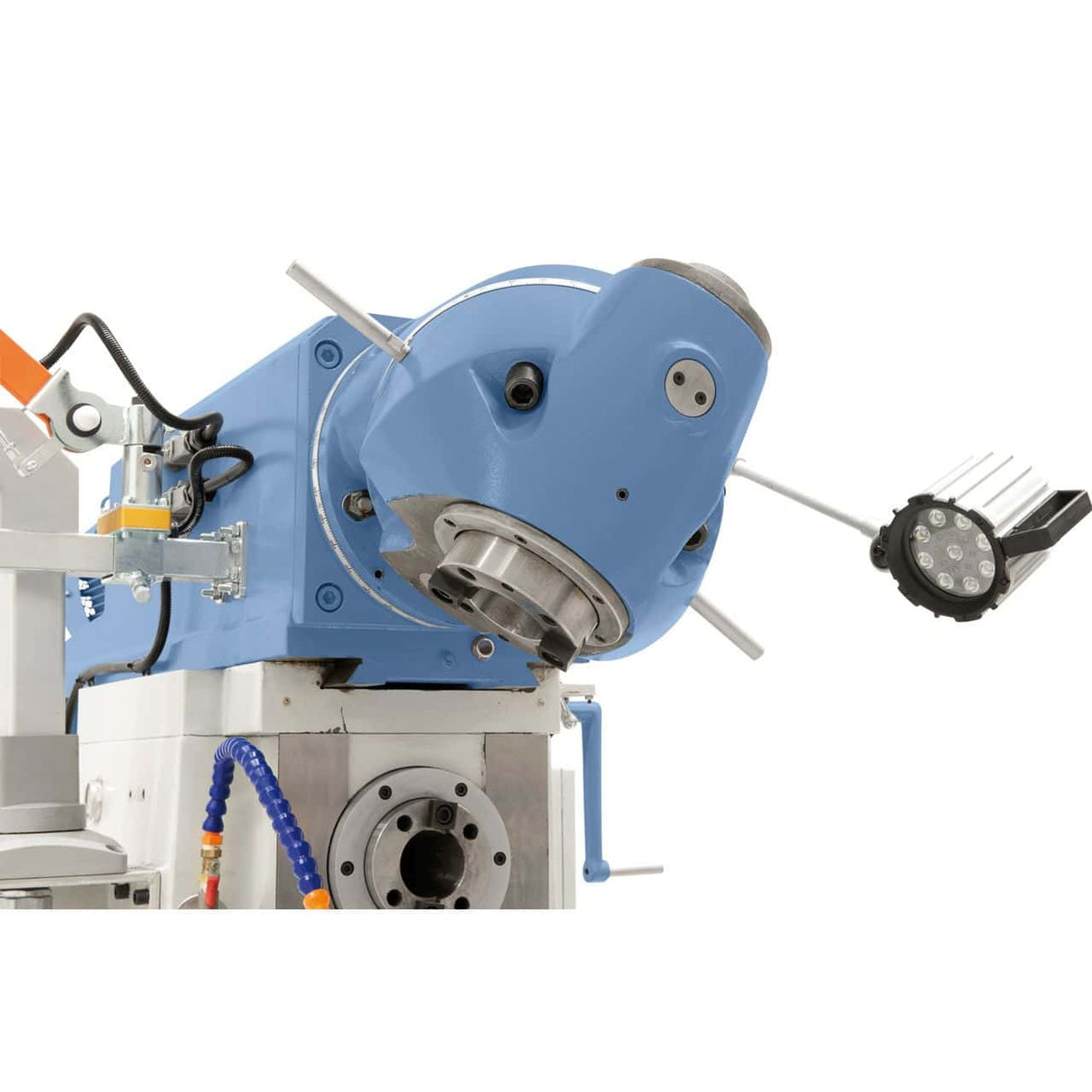

- Universal Milling Head : The universal milling head of the "Huron" system is fully adjustable in all angular positions, increasing flexibility in milling operations.

- Central Lubrication : The machine is equipped with a centralized lubrication system for the X, Y and Z axes, reducing wear and ensuring long operating life.

Standard Accessories:

- ES-12 H 3-Axis Position Display with LCD Display

- M 24 clamping chuck

- LED car light

- Refrigeration system with cooling tank

- Horizontal external support

- Universal protection device

- Long and combined drilling chucks (ISO 50/27 mm, ISO 50/32 mm)

- ISO 50 / MK 4 reduction socket

- Feed on all axes (X, Y, Z)

- Automatic central lubrication for X and Y axes

- Advanced control device

Technical Specifications :

| Characteristic | Detail |

|---|---|

| Table dimensions | 1600 x 360 mm |

| Horizontal spindle attachment | ISO 50 |

| Vertical spindle attachment | ISO 50 |

| Horizontal spindle speed | (12) 60 – 1800 rpm |

| Number of revolutions of the vertical spindle | (2) 60 – 350 / 350 – 1750 rpm |

| Longitudinal travel (X) | 1300 mm |

| Transverse stroke (Y) | 300 mm |

| Vertical stroke (Z) | 400 mm |

| Distance between spindle and horizontal table | 15 – 415 mm |

| Distance between spindle and vertical table | 185 – 585 mm |

| Length of the arms | 215 – 840 mm |

| Tilting table | from -45° to +45° |

| Maximum piece weight | 300 kg |

| Longitudinal advancement area | (8) 30 – 750 mm/min |

| Transverse advancement area | (8) 20 – 500 mm/min |

| Vertical advancement area | (8) 15 – 375 mm/min |

| Rapid travel X, Y, Z axes | 1200 / 800 / 600 mm/min |

| T-slots (number, width, spacing) | 3 / 18 mm / 80 mm |

| Horizontal engine power | 5.5 kW |

| Vertical motor power | 5.5 kW |

| Servo motor (torque / power) | 10 Nm / 1.5 kW |

| Pump power for coolant circulation | 90 W |

| Coolant circulation pump flow rate | 25 l/min |

| Machine dimensions (L x W x H) | 2530 x 2200 x 2300 mm |

| Weight | 2695 kg |

The UWF 150 V Servo Universal Milling Machine is ideal for high-precision, versatile industrial machining. Thanks to its variable spindle speed control, robust construction, and flexible universal milling head, this machine offers high performance even for the most complex operations. Numerous standard accessories and a centralized lubrication system ensure efficient and reliable operation over time.