FKS 2800 Pro squaring machine - 400V

FKS 2800 Pro squaring machine - 400V is backordered and will ship as soon as it is back in stock.

Subscribe to our newsletter

Get the latest updates on all our new collections, sales, offers and product arrival dates.

-

Description

-

Technical Specifications

-

Product safety

-

Reviews

Description

Sliding table circular saw FKS 2800 Pro / 400 V

The FKS 2800 Pro is a sliding circular saw designed for professional woodworkers seeking precision, power, and high operating capacity . The 2800 mm table , 315 mm blade , and integrated scoring saw enable clean cuts up to 100 mm, even on coated panels. The cast iron and steel body, 3.8 kW motor , and large table extensions ensure stability and versatility on large materials. A solid and reliable machine, ready for intensive work.

Main features

• Use of the 315 mm blade even with the engraver mounted

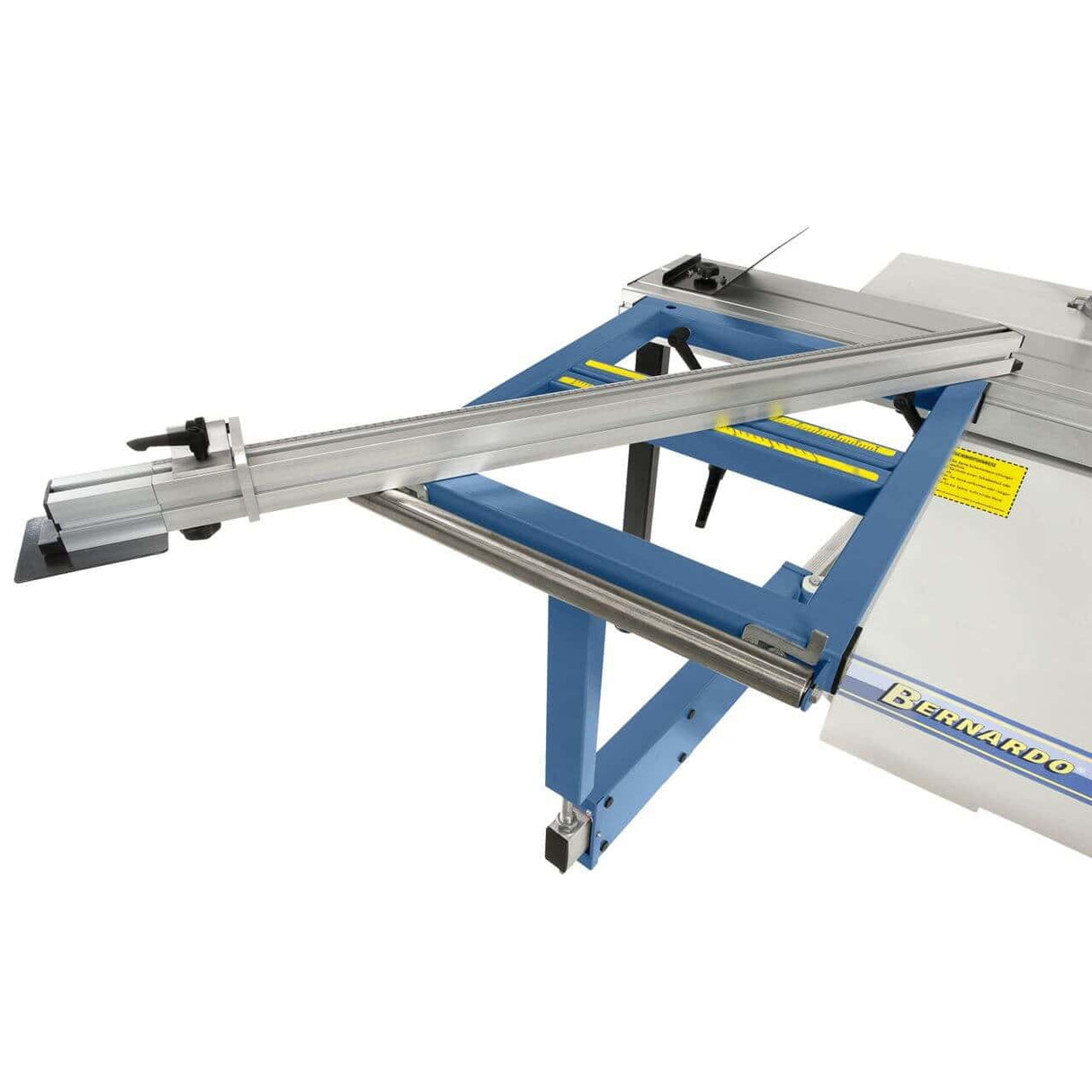

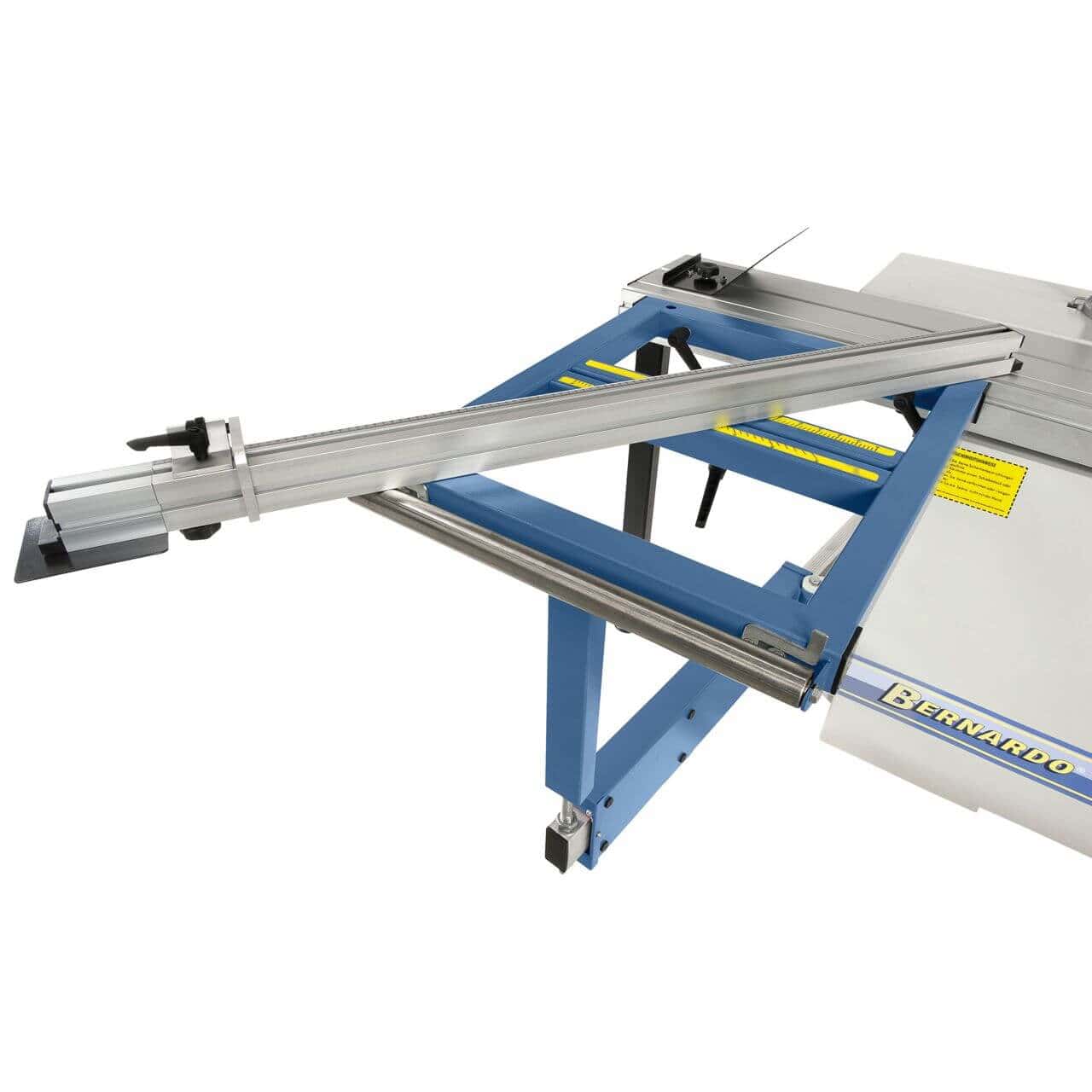

• 2800 mm sliding carriage in anodized aluminum with tempered guides

• Square table with roller and telescopic arm for maximum stability

• Powerful 3.8 kW motor for continuous cuts even on thicknesses of 100 mm

• Blade tiltable from 90° to 45° via handwheel and graduated scale

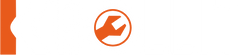

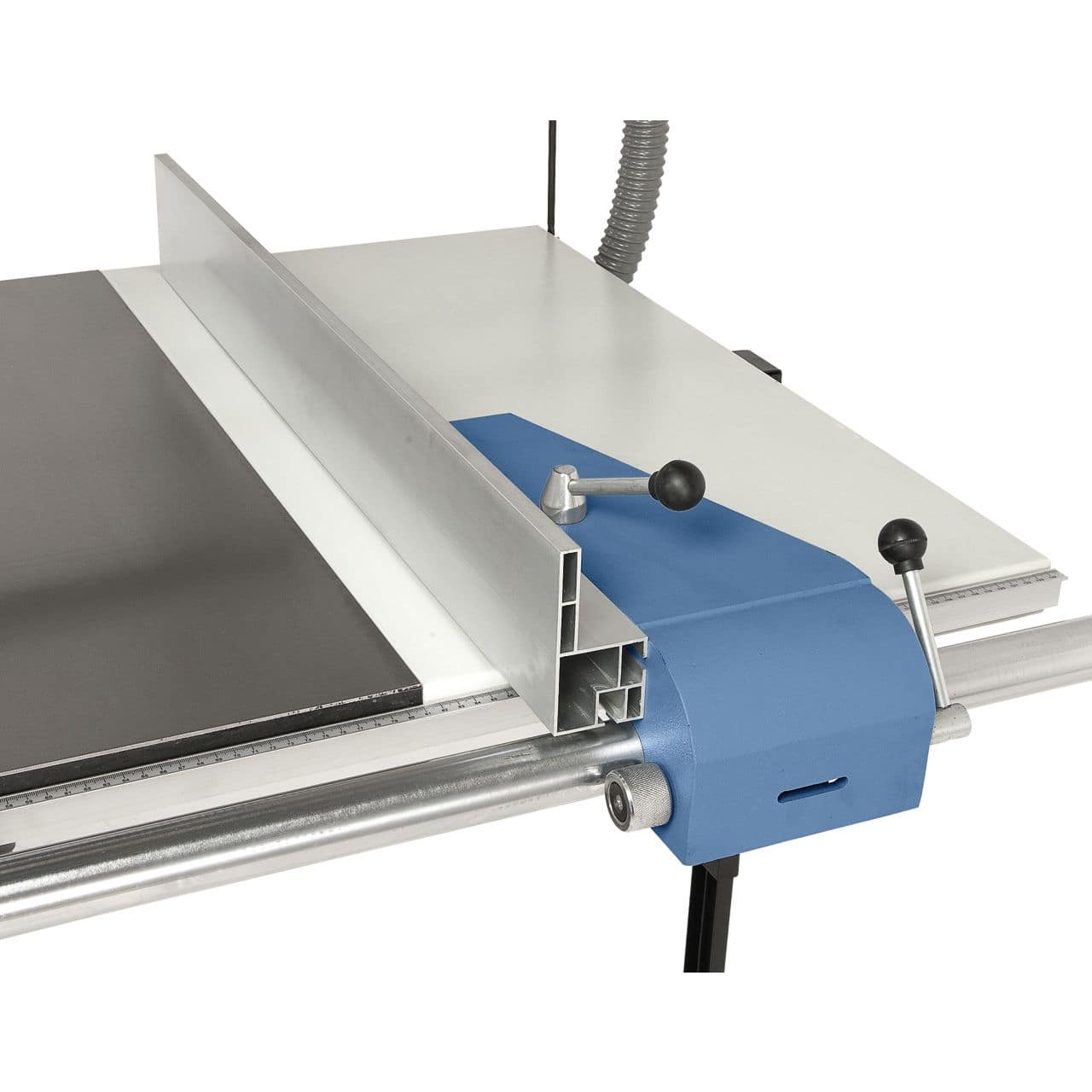

• Aluminum parallel guide with micrometric adjustment and integrated lens

• Telescopic guide extendable up to 2260 mm, can be mounted on the front or back of the table

• Extensions and widenings to support panels up to 1200 mm

• Torsionally rigid steel and cast iron structure

• Compact, stable and vibration-free saw unit

Technical data

| Technical specifications | |

|---|---|

| Table size | 800 x 380 mm |

| Sliding carriage | 2800 x 270 mm |

| Cutting length | 2800 mm |

| Maximum blade diameter | 315 x 30 mm |

| Max. cutting height 90° / 45° | 100 / 80 mm |

| Cutting width on parallel guide | 1200 mm |

| Table height | 870 mm |

| Table extension | 500 x 310 mm |

| Table enlargement | 800 x 880 mm |

| Square table with roller | 880 x 580 mm |

| Main blade speed | 4000 rpm |

| Engraving blade speed | 5800 rpm |

| Engraving blade | 90 x 20 mm |

| Suction outlet | Ø 100 mm |

| Engine power (S1 100%) | 3.8 kW (5.1 HP) |

| Engine power (S6 40%) | 5.3 kW (7.2 HP) |

| Voltage | 400 V |

| Machine dimensions (L x W x H) | 2800 x 2900 x 1180 mm |

| Weight approx. | 324 kg |

Package Contents

• HM blade 315 x 3.0 x 30 mm / 40 teeth

• Scoring blade 90 x 3.0 x 20 mm / 12 teeth

• Protective casing with suction connection

• Connection pipe with Y-fitting

• Corner stop with eccentric support

• Corner stop

• End of stroke stop

• Table extension

• Table enlargement

• Parallel guide

• Extractable telescopic guide

• Fine adjustment of the beat

• Square table

• Push handle

• Pusher

• Tool set

Technical Specifications

• Main blade and engraver well tightened

• Protective casing correctly mounted

• Table free from materials

• Extractor fan connected to the 100 mm outlet

• Check the fluidity of the carriage

• Idle start to test rotation

Every week: check and tighten screws, grease guides

Monthly: check alignments, belt tension and clean engine compartment

All operations must be carried out with the machine switched off and unplugged.