Bernardo | SKU:

03-1258

Pre-order

Standard 165 Plus Lathe

€5.660,00

Unit price

/

Unavailable

Tax included

Shipping calculated at checkout.

Standard 165 Plus Lathe is backordered and will ship as soon as it is back in stock.

Subscribe to our newsletter

Get the latest updates on all our new collections, sales, offers and product arrival dates.

-

Description

-

Technical Specifications

-

Product safety

-

Reviews

Description

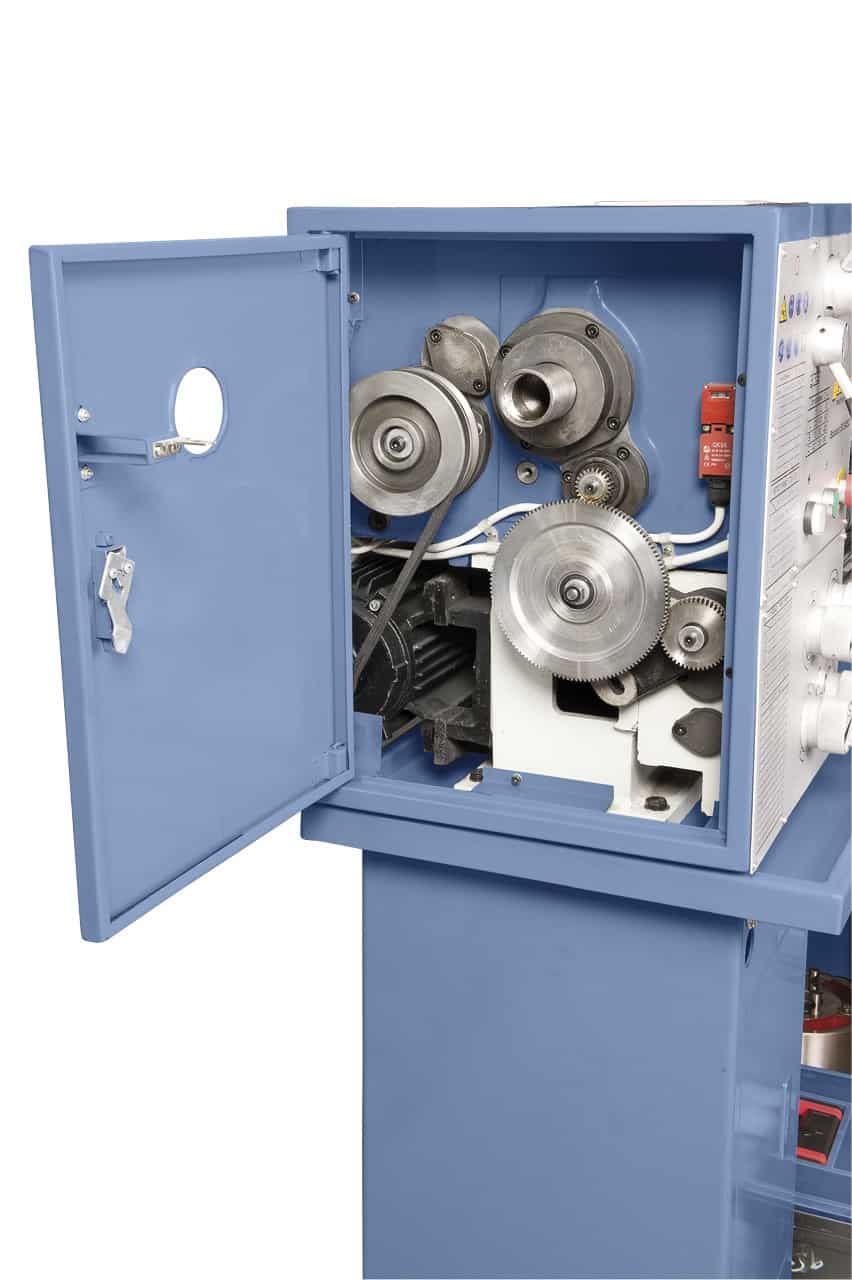

The Standard 165 Plus lathe represents a further evolution of the proven 150 series. The feed drive has been revised for ease of use, and the gear head design has taken on a modern look. Ideal for DIY enthusiasts, it offers a comprehensive range of standard accessories, making this machine excellent in terms of price and benefits.

Property

- Wide range of applications: training seminars, toolmaking, repair services, ...

- Prismatic base made of grey cast iron, inductively hardened and precision ground

- The speed and feed adjustment is simple in structure, smooth and can be activated precisely.

- Very convenient machine, equipped with a guide spindle and a shaft spindle for threading and automatic feed

- Lever lock for tailstock, adjustable for taper turning

- The removable bridge allows the machining of large diameter workpieces

- Spindle bearing with 2 adjustable precision bearings

- Hardened and ground gears and shafts

- Space-saving installation possible thanks to the front-extractable chip collection tray

- Electromechanical foot brake for reduced downtime

Standard accessories

- 3-jaw chuck DK11-160 mm / D4

- Platform 200 mm / D4, according to DIN 55029

- Fixed bezel - max. diameter 60 mm

- Rotating bezel - max. diameter 60 mm

- Clamping plate 250 mm

- Quadruple tool holder

- Quadruple tool holder protection device

- Shaft fastening device

- Slip joint

- Longitudinal stop of the micrometer

- Refrigeration system

- Removable chip collection tray

- Motor with magnetic brake according to CE standard

- Pedal with brake function according to CE standards

- Mudflaps

- Thread gauge

- LED car light

- Reduction compass

- Replacement wheels

- 2 central tips

- Base

- Control device

technical specifications

| Distance between tips | 1000 mm |

| Height of the tips | 175 mm |

| Vaulting on the table | 350 mm |

| Vault on the elbow bend | 450 mm |

| Vaulting on flat sleds | 190 mm |

| Bed width | 180 mm |

| Spindle hole | 40 mm |

| Spindle attachment | DIN 55029, D1-4 |

| Speed range | (8) 70 - 2000 rpm |

| Longitudinal advancement area | (40) 0.053 - 1.29 mm/rev |

| Floor progress area | (40) 0.013 - 0.31 mm/rev |

| Metric threads | (32) 0.4 - 7 mm |

| Inch threads | (36) 4 - 60 TPI |

| Spindle stroke | 110 mm |

| Spindle support | MK 3 |

| S1 motor input power 100% | 1.5 kW (400 V) |

| S6 Motor Output Power 40% | 2.2 kW (400 V) |

| Machine dimensions (L x W x H) | 1730 x 700 x 1340 mm |

| Weight approx. | 495 kg |

Technical Specifications

Posiziona il tornio (peso ~495 kg) sullo stand fornito e mettilo in bolla.

Collega l’alimentazione trifase 400 V, monta mandrini e ripari, quindi esegui il livellamento fine

del bancale con comparatore su barra di riscontro finché la conicità è nulla su 200–300 mm.

Ingombro: 1730 × 700 × 1340 mm.

Distanza punte 1000 mm, altezza punte 175 mm (Ø banco 350 mm),

Ø su carro trasversale 190 mm, larghezza bancale 180 mm,

foro mandrino Ø 40 mm con attacco D1-4.

Con letto amovibile 220 mm si lavora sull’incavo fino a Ø 450 mm.

Cambio meccanico a 8 step con gamma 70–2000 rpm.

Seleziona lo step secondo tabella e imposta i giri in base a materiale, utensile e diametro pezzo.

Il motore ha freno magnetico e c’è il pedale freno CE per arresto rapido.

Metriche: 32 passi 0,4–7 mm. In pollici: 36 passi

4–60 TPI. Avanzamenti longitudinali 0,053–1,29 mm/giro (40) e trasversali

0,013–0,31 mm/giro (40). Inclusi ingranaggi cambio e thread dial.

Mandrino autocentrante DK11 Ø 160 mm (D4), mandrino indipendente Ø 200 mm (D4),

piastra frontale Ø 250 mm, lunetta fissa e mobile (passaggio Ø 60 mm),

torretta a 4 posizioni con protezione, dispositivo refrigerante, vasca trucioli estraibile, paraspruzzi,

frizione di sicurezza, battuta longitudinale micrometrica, luce LED, bussola Morse,

ingranaggi di cambio, 2 contropunte, stand e set utensili.

Motore 1,5 kW in S1 e 2,2 kW in S6 40%, alimentazione

trifase 400 V. Verifica protezioni (magnetotermico/differenziale), messa a terra e funzionamento del freno magnetico e del pedale freno CE.

Sì. Rimuovendo il letto amovibile (220 mm) è possibile lavorare fino a Ø 450 mm sull’incavo.

Usa serraggi adeguati, giri compatibili e, se necessario, le lunette per supportare il pezzo.

Pulisci vasca e guide dopo l’uso, lubrifica slitte e vite madre, controlla livelli/refrigerante e trafilamenti,

verifica giochi dei carri/chiocciole e tensione cinghie. Mantieni efficienti ripari, microinterruttori, luce LED e freno.