Metal turning requires precision and reliability. Choosing the right lathe determines quality, productivity, and business competitiveness. Each type meets specific processing needs.

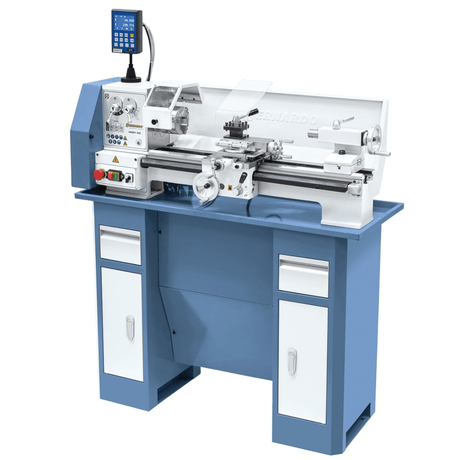

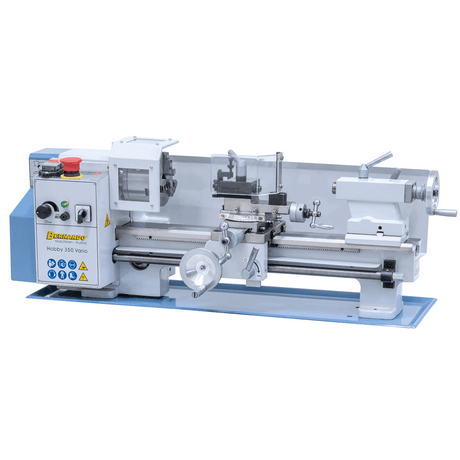

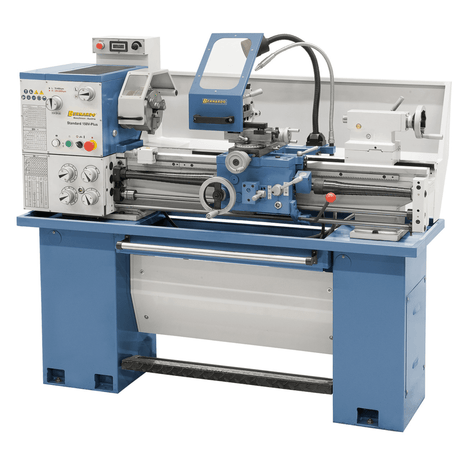

Benchtop Lathes - Compact Solutions

THEbench lathes for metalThey offer professional performance in a compact size. The tempered cast iron structure, ground prismatic guides, and self-centering spindles ensure precision on workpieces up to 300 mm in diameter.

Operating specifications:

- Distance between tips: 300-500mm for versatility

- Motor power: 350-750W for different materials

- Speed: 100-2500 rpm adjustable

- Weight: 30-80kg for optimal stability

Ideal for workshops, educational labs, and advanced hobbyists. They work steel, aluminum, and brass with professional finishes.

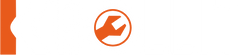

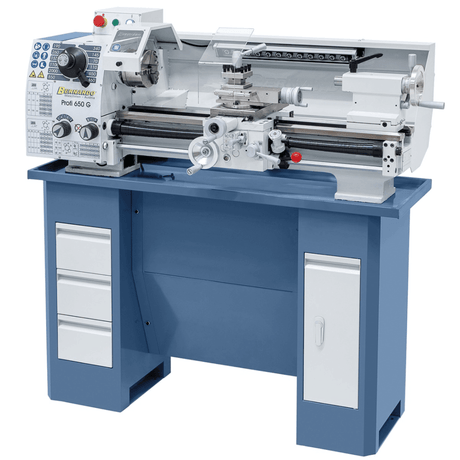

Universal Lathes - Maximum Flexibility

Variable Speed Control

THEuniversal lathes with continuous speed variationThey automatically adapt to any material. The electronic inverter optimizes cutting and surface finishing without machine downtime.

Integrated Digital Displays

THEuniversal lathes with digital displaysThey integrate DRO displays for precise measurements. Measurement storage, programmable presets, and automatic coordinate calculation speed up repetitive operations.

Complete works:

- External/internal cylindrical turning

- Metric and inch thread

- Axial and off-center drilling

- Cutting and exhaust throats

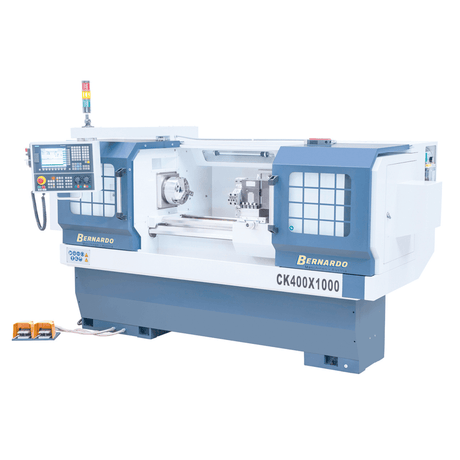

CNC Automation

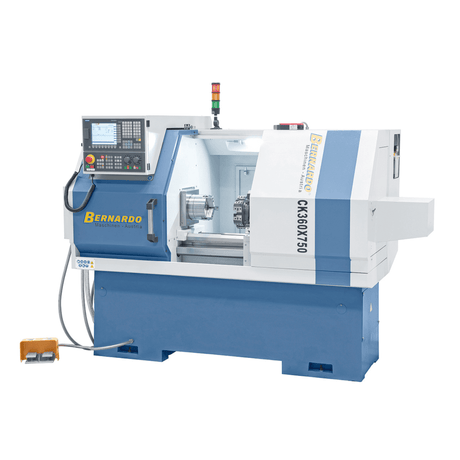

THECNC lathesThey execute complex programs with consistent precision. Siemens controls, AC servomotors, and ball screws ensure micrometric repeatability for series production.

Integrated technologies:

- Siemens 828D numerical control

- Motorized tool turrets

- 3D anti-collision simulation

- Automatic tool wear monitoring

Ideal for precision components and medium-large batches.

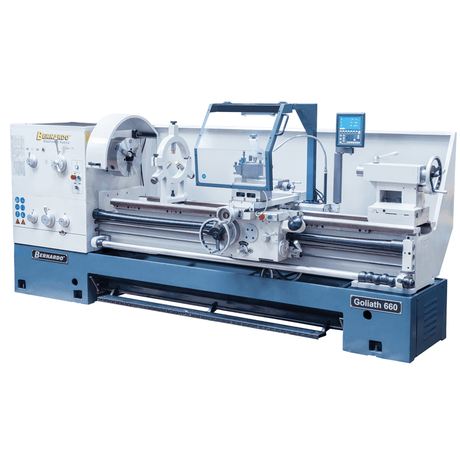

Heavy Industrial Lathes

THEheavy lathesThey handle large parts for the naval, energy, and mining industries. Reinforced Meehanite bed, power up to 75 kW, and load capacity up to 10 tons.

Industrial capacities:

- Distance between tips: 1500-6000mm

- Maximum diameter: 500-1500mm

- Integrated auxiliary systems

- Automatic centralized lubrication

Specialized Solutions

Traditional Mechanical Lathes

THEmechanical lathesThey maintain construction simplicity with high performance. Norton gearbox, direct mechanical transmission, and superior environmental resistance for heavy-duty industrial applications.

Advanced Systems

THEgear lathes/slip coupling/drive shaftThey use sophisticated transmissions for precise synchronization. Overload protection and repeatable threads.

Work Centers

THEwork center lathesThey combine turning and milling, eliminating multiple reworks. Setup times are reduced by 60% and geometric accuracy is improved.