Bernardo

BFM 2100 Servo Benchtop Milling Machine with 3-Axis Digital Display ES-12 H

€72.980,00Unit price /UnavailableBernardo

KF 20 L Drill and Milling Combo with Twist Drill Bit Set

€999,00€1.055,30Unit price /UnavailableBernardo

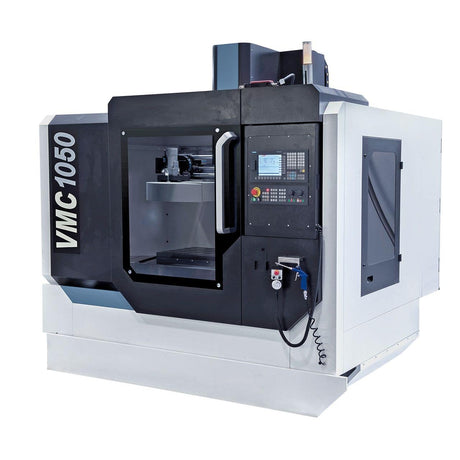

CNC vertical machining center VMC 1050 with Siemens Sinumerik 808D Advanced 16

€60.536,00Unit price /UnavailableBernardo

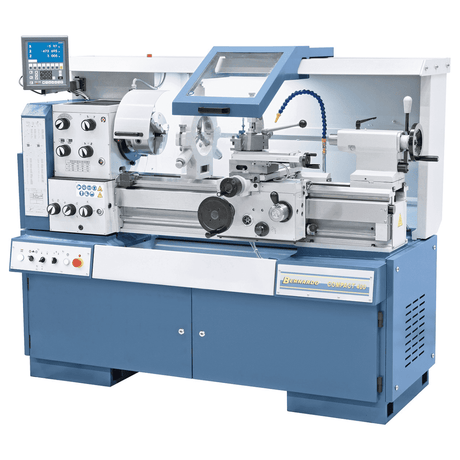

Master 360 Pro Vario universal lathe incl. 3-axis digital display

€10.638,40Unit price /UnavailableBernardo

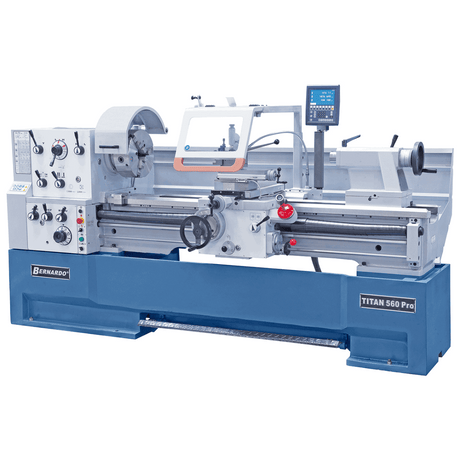

Titan 560 x 3000 Pro Universal Lathe with Digital Displays

€32.000,20Unit price /UnavailableBernardo

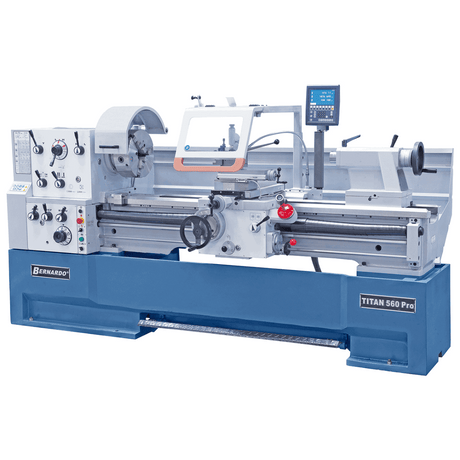

Titan 560 x 2000 Pro Universal Lathe with Digital Displays

€27.800,00Unit price /UnavailableBernardo

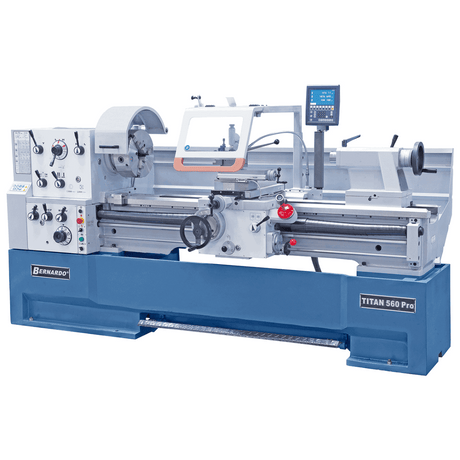

Titan 560 x 1500 Pro Universal Lathe with Digital Displays

€24.900,40Unit price /UnavailableBernardo

Master 180 Universal Lathe with Digital Display, Including 3-Axis Digital Display

€7.734,80Unit price /UnavailableBernardo

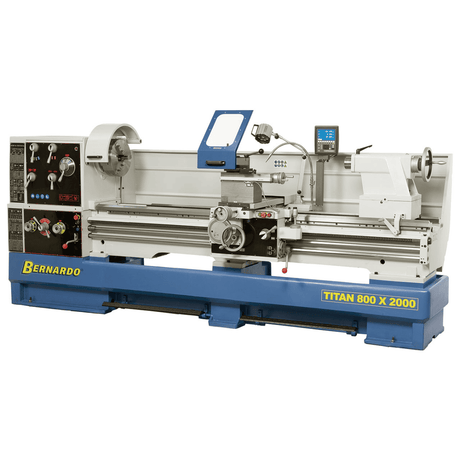

Titan 800 x 3000 Vario Continuous Speed Universal Lathe

€43.600,00Unit price /UnavailableBernardo

Titan 800 x 2000 Vario Continuous Speed Universal Lathe

€39.700,20Unit price /UnavailableBernardo

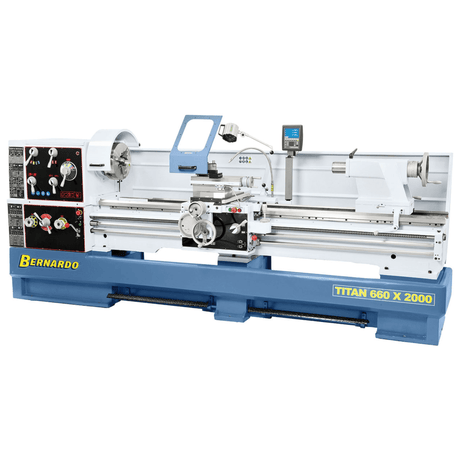

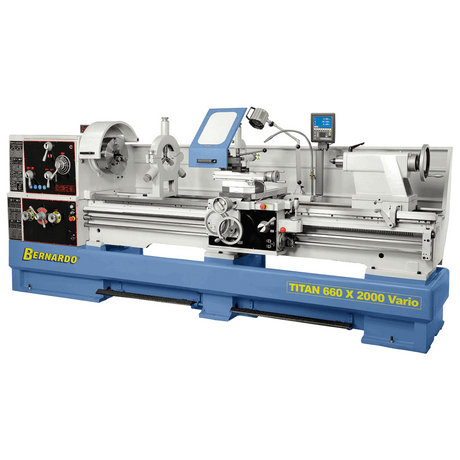

Titan 660 x 3000 Vario Continuous Speed Universal Lathe

€41.400,00Unit price /UnavailableBernardo

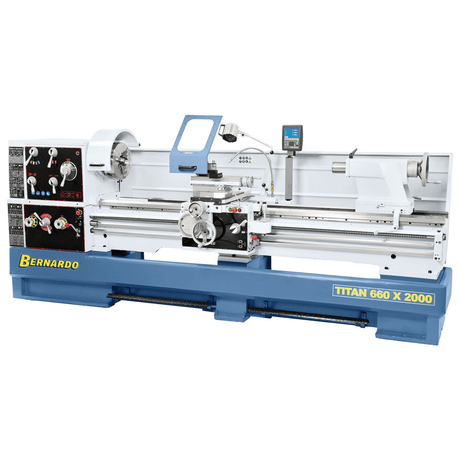

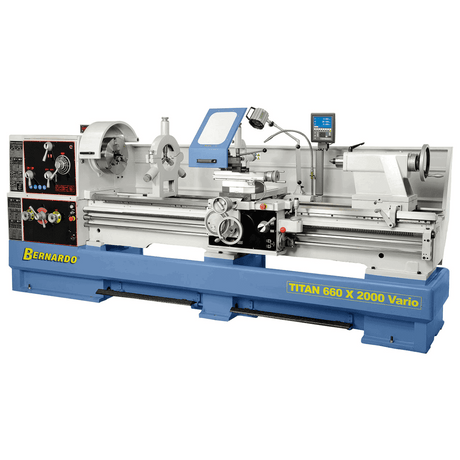

Titan 660 x 2000 Vario Continuous Speed Universal Lathe

€37.800,80Unit price /UnavailableBernardo

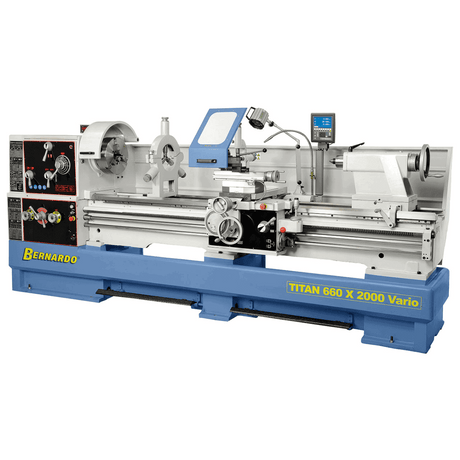

Titan 660 x 1500 Vario Continuous Speed Universal Lathe

€34.600,20Unit price /UnavailableBernardo

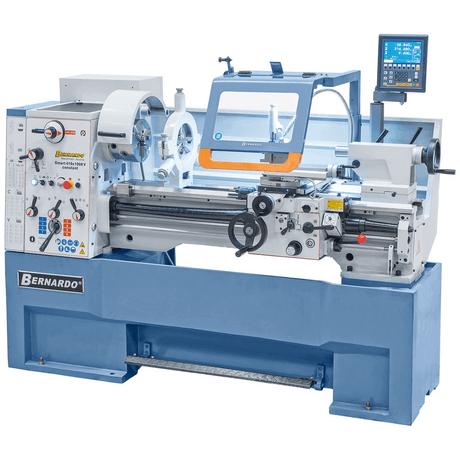

Titan 560 x 2000 Pro Vario Continuous Speed Universal Lathe

€32.000,20Unit price /UnavailableBernardo

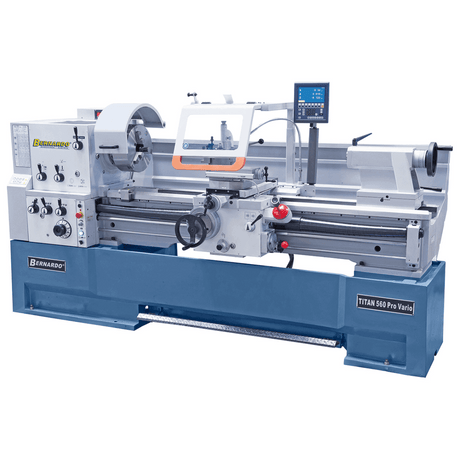

Titan 560 x 1500 Pro Vario Continuous Speed Universal Lathe

€29.000,40Unit price /UnavailableBernardo

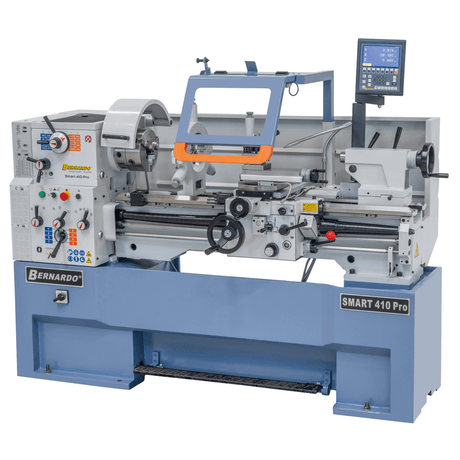

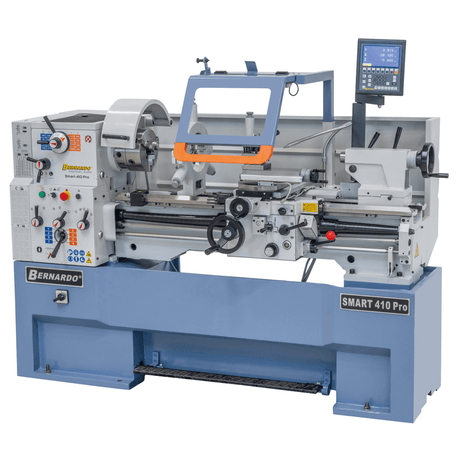

Smart 410 x 1500 Vario Continuous Speed Universal Lathe

€19.300,20Unit price /UnavailableBernardo

Smart 410 x 1500 V-constant continuous speed universal lathe

€20.990,60Unit price /UnavailableBernardo

Smart 410 x 1000 V-constant continuous speed universal lathe

€19.600,60Unit price /Unavailable

Frequently Asked Questions

Quali macchine servono per aprire una piccola officina?

Quali macchine servono per aprire una piccola officina?

Meglio macchine monofase 230V o trifase 400V?

Meglio macchine monofase 230V o trifase 400V?

Meglio un tornio convenzionale o CNC per iniziare?

Meglio un tornio convenzionale o CNC per iniziare?

Che differenza c'è tra trapano a colonna e trapano-fresa?

Che differenza c'è tra trapano a colonna e trapano-fresa?

Quali sono i costi di manutenzione ordinaria?

Quali sono i costi di manutenzione ordinaria?

Quanto spazio serve per una piccola officina attrezzata?

Quanto spazio serve per una piccola officina attrezzata?